Testing device of desulphurization efficiency and testing method thereof

A technology for desulfurization efficiency and testing device, applied in measurement devices, chemical method analysis, instruments, etc., can solve problems such as high cost, high consumption, affecting test results, etc., achieve accurate and reliable experimental data, simplify experimental steps, and reduce experimental costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

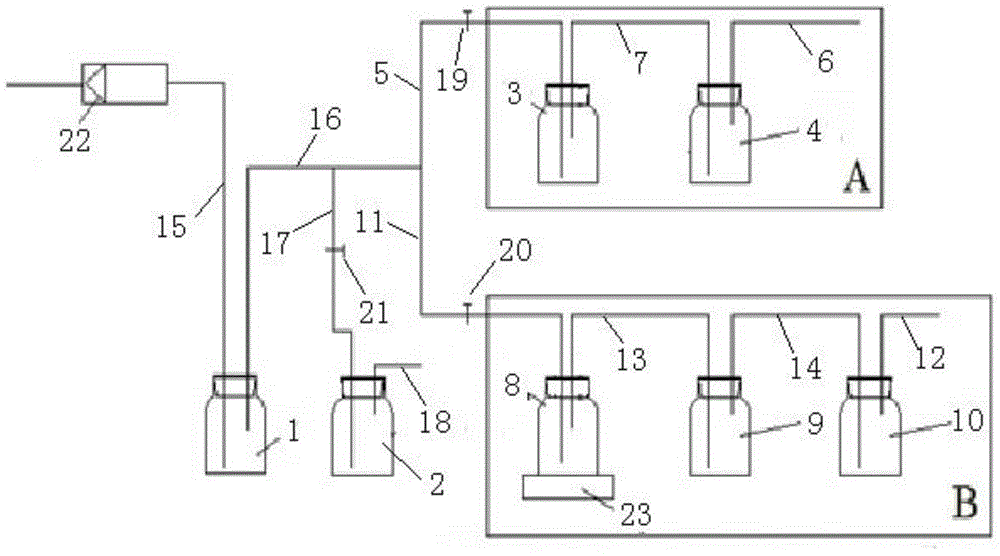

[0026] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0027] As shown in the figure, a kind of desulfurization efficiency testing device of the present invention comprises buffer bottle 1, SO 2 Absorption bottle I2, A absorption system and B absorption system;

[0028] The A absorption system includes SO 2 Absorption bottle Ⅱ3 and SO 2 The absorption bottle III4, the SO2 absorption bottle II3 is provided with an air inlet pipe I5, and the SO 2 The absorption bottle III4 is equipped with an exhaust pipe I6, and the SO 2 Absorption bottle Ⅱ3 and SO 2 The absorption bottle Ⅲ4 communicates through the connecting pipe Ⅰ7;

[0029] The B absorption system includes limestone slurry bottle 8, SO 2 Absorption bottle Ⅳ9 and SO 2 Absorption bottle V10, the limestone slurry bottle 8 is provided with an air inlet pipe II11, the SO 2 The absorption bottle V10 is provided with an exhaust pipe II12, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap