Battery degradation state model-based lithium ion battery cycle life prediction method

A lithium-ion battery and state model technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as difficult modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

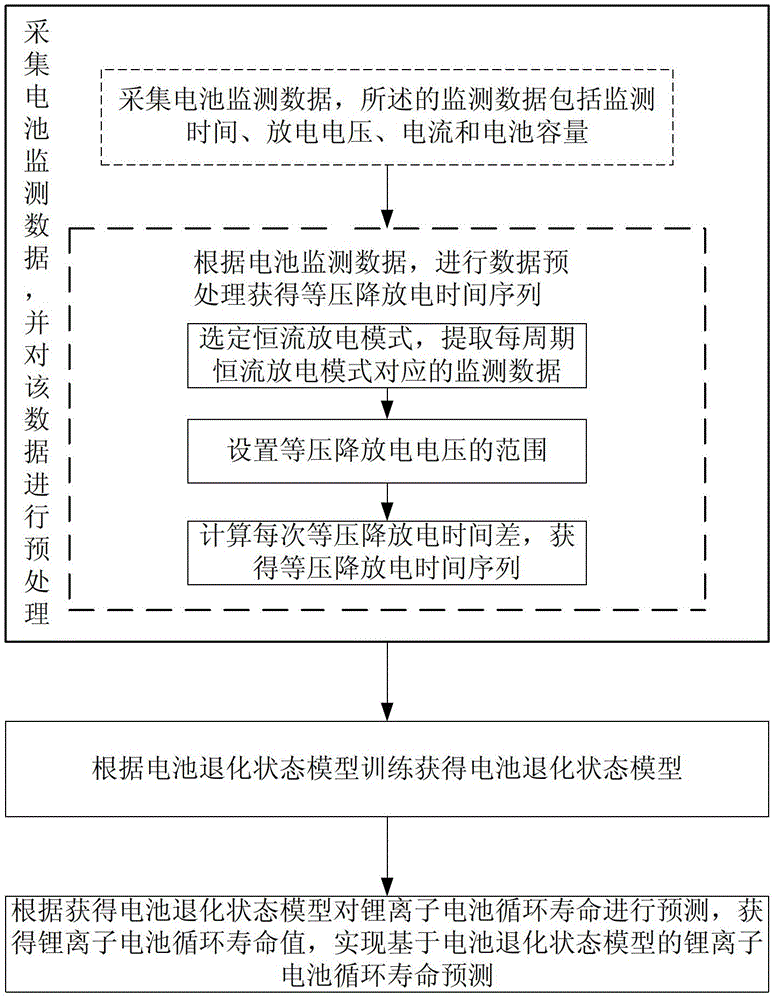

[0045] Specific implementation mode 1. Combination figure 1 Specifically explaining this embodiment, the lithium-ion battery cycle life prediction method based on the battery degradation state model described in this embodiment includes the following steps:

[0046] Step 1. Collect battery monitoring data and preprocess the data;

[0047] Step 2. Obtain the battery degradation state model according to the battery degradation state model training,

[0048] Step 3: Predict the cycle life of the lithium-ion battery based on the battery degradation state model obtained in step 2, obtain the cycle life value of the lithium-ion battery, and realize the cycle life prediction of the lithium-ion battery based on the battery degradation state model.

specific Embodiment approach 2

[0049]Specific Embodiment 2. The difference between this embodiment and the lithium-ion battery cycle life prediction method based on the battery degradation state model described in the specific embodiment 1 is that the battery monitoring data described in step 1 is collected and the data is preprocessed. The specific process is:

[0050] Step 11, collecting battery monitoring data, the monitoring data includes monitoring time, discharge voltage, current and battery capacity;

[0051] Step 12: According to the battery monitoring data, data preprocessing is performed to obtain a discharge time series with equal pressure drop.

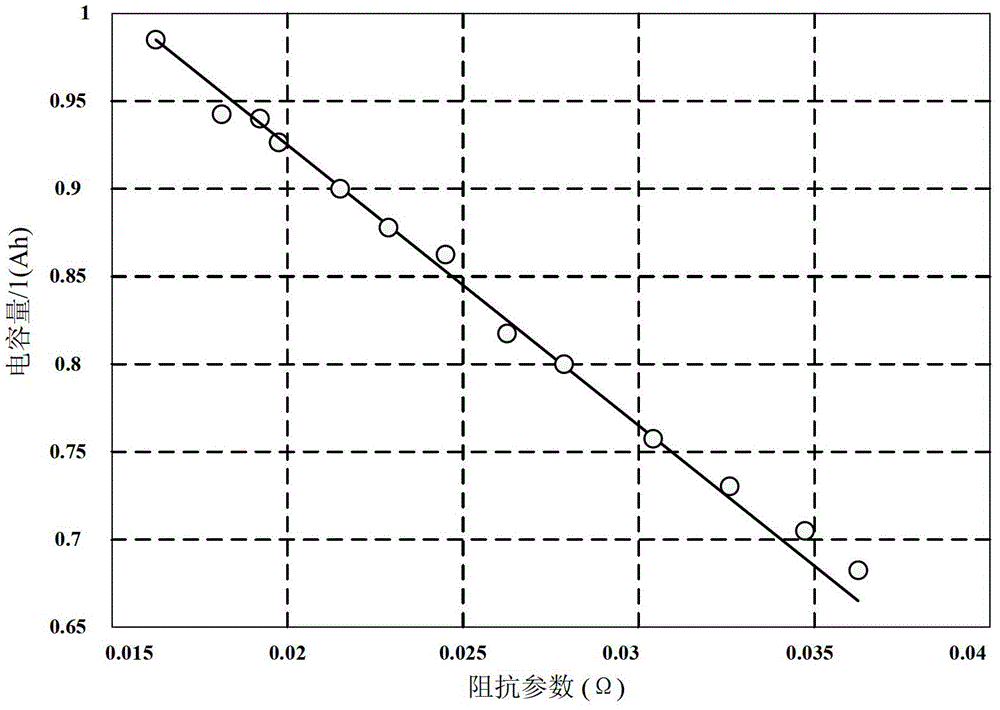

[0052] Through the gray relational analysis, it can be seen that the correlation degree between the equal pressure drop discharge time series and the battery capacity series described in this embodiment is relatively large, that is, the equal pressure drop discharge time can be used to characterize the battery capacity.

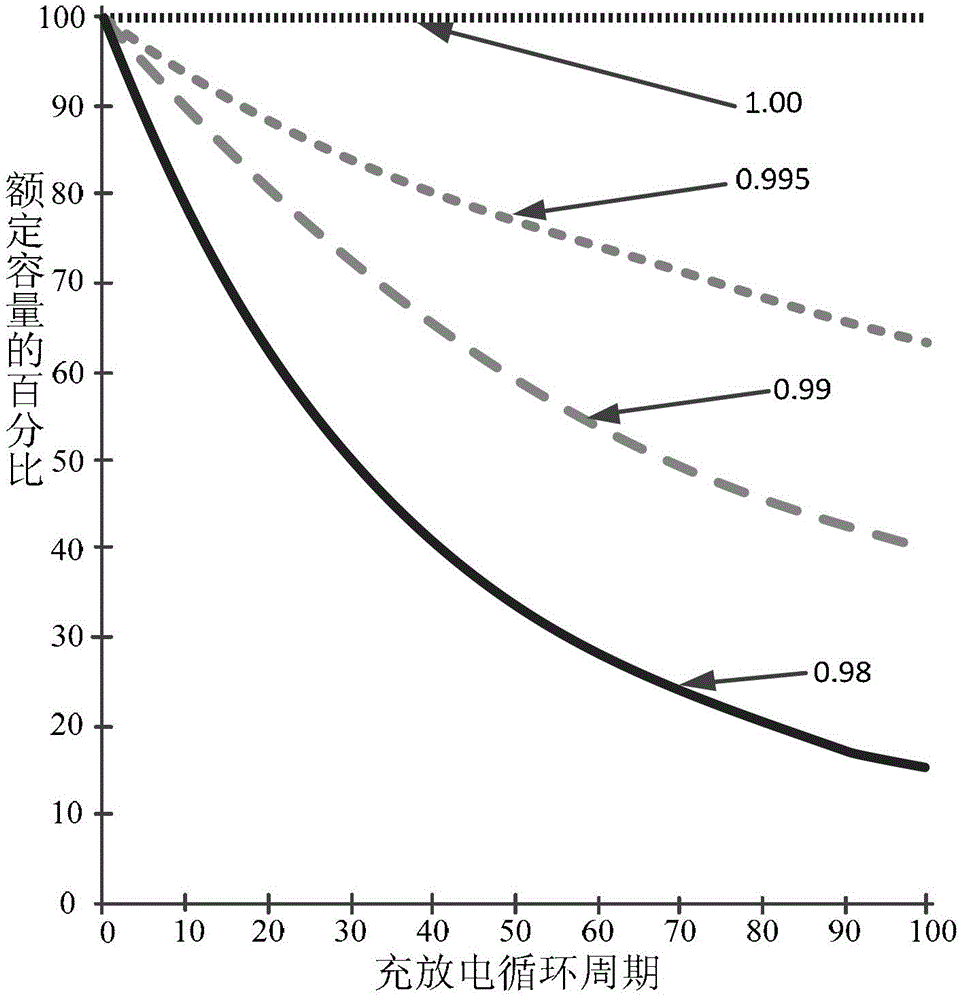

[0053] The lithium-ion battery...

specific Embodiment approach 3

[0067] Specific Embodiment 3. The difference between this embodiment and the lithium-ion battery cycle life prediction method based on the battery degradation state model described in Embodiment 2 is that the specific process of obtaining the discharge time series with equal pressure drop described in steps 1 and 2 is as follows: :

[0068] Step 121, select the constant current discharge mode, and extract the monitoring data corresponding to the constant current discharge mode per cycle;

[0069] Step 122, setting the range of equal pressure drop discharge voltage;

[0070] Step 1, 2, and 3: Calculate the time difference of equal-voltage-drop discharge each time, and obtain the time series x(n) of equal-voltage-drop discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com