A trigger mechanism for a water level switch

A technology of trigger mechanism and water level switch, applied in liquid level control, non-electric variable control, instruments, etc., can solve the problems of cumbersome setting, uneconomical, and shorten the service life of equipment, and achieve unique float design and low secondary cost. , reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

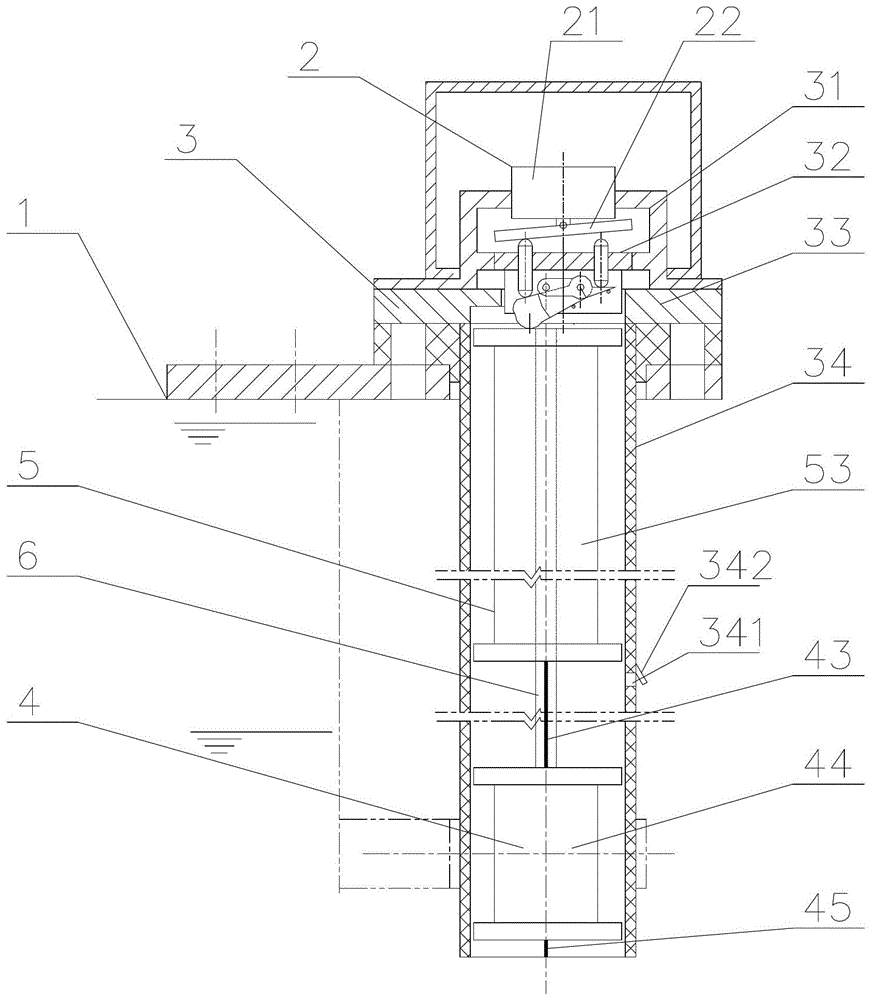

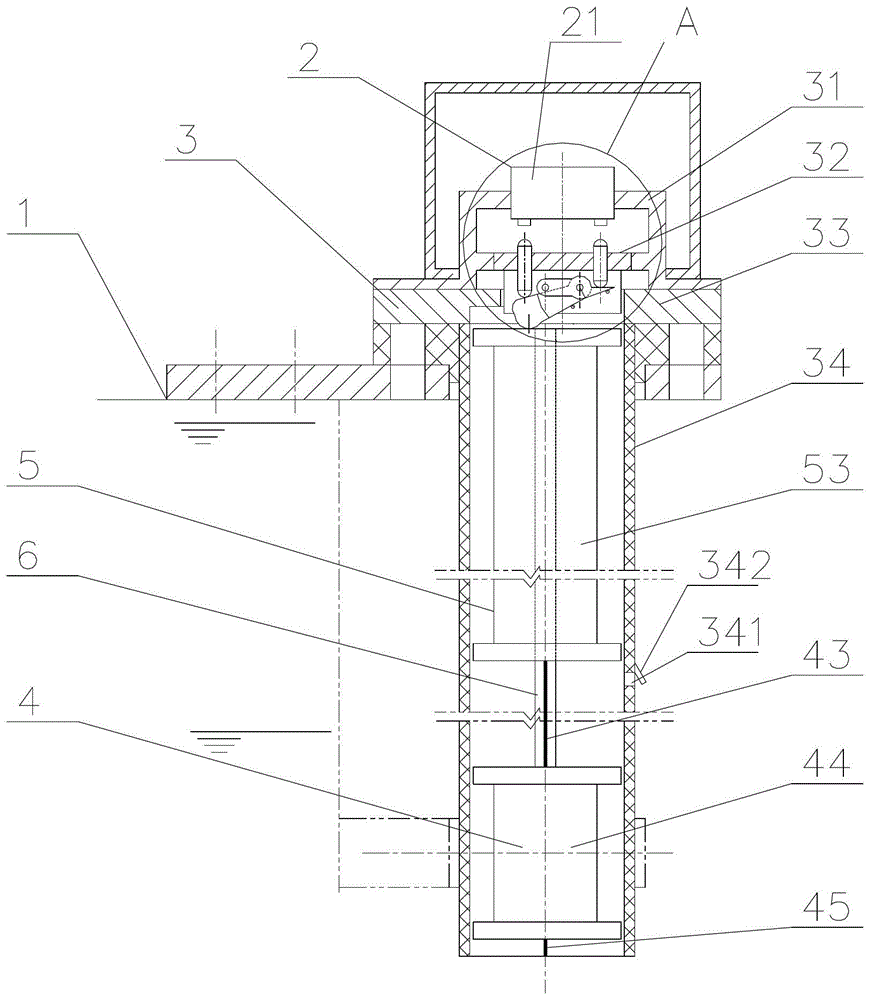

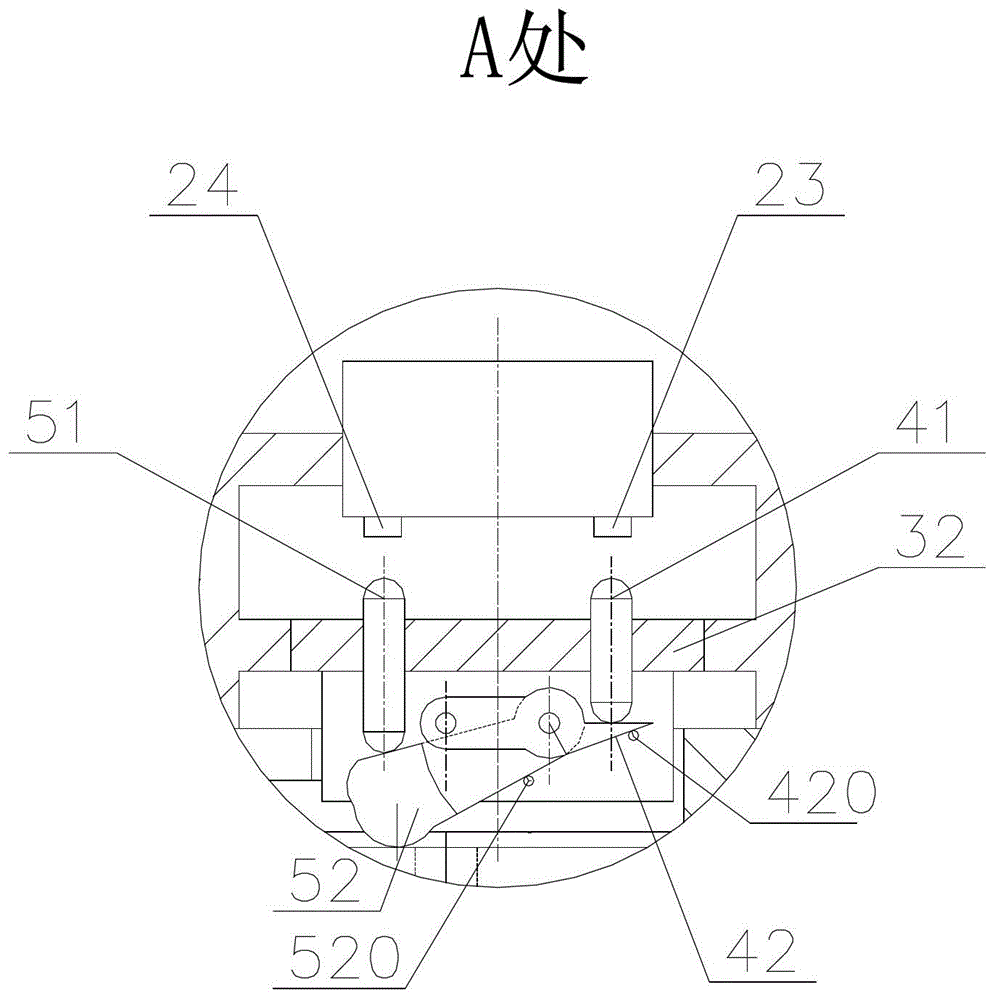

[0053] The invention as Figure 1-8 As shown, the trigger mechanism includes a housing assembly 3, a water replenishment mechanism 4 and a water shutoff mechanism 5;

[0054] The housing assembly 3 includes a base 32 , a connecting plate 33 and a sleeve 34 sequentially from top to bottom, the base 32 is provided with a water supply hole and a water closing hole, and the connecting plate 33 is provided with an accommodating hole ;

[0055]The water shut-off mechanism 5 includes a water shut-off jack 51, a floating pendulum 52 and a float 53, the water shut-off jack 51 is set in the water shut-off hole, and the float 53 is set in the casing 34; One end of the floating pendulum 52 is hinged in the accommodating hole, and the other end is arranged between the water-closing jack 51 and the float 53, so that the float 53 drives the water-closing jack through the floating pendulum 52. Rod 51 moves up and down;

[0056] The water replenishment mechanism 4 includes a water replenish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com