A positive electrode of energy storage photosensitive solar cell and preparation method thereof

A solar cell and cathode technology, applied in photosensitive equipment, circuits, capacitors, etc., can solve the problems of bulky size, inconvenient universal application, complex solar cell composition, etc., and achieve the effect of uniform coating of the cathode and good power storage function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

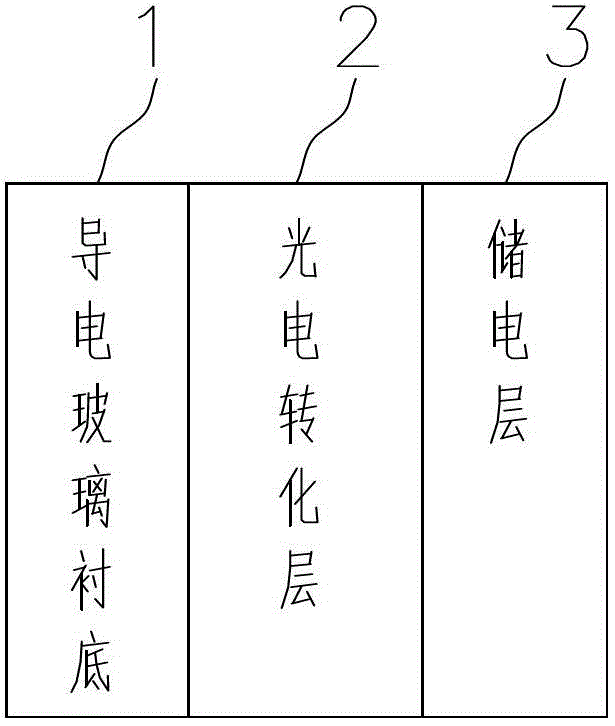

[0025] Add 1 mL of 0.15 mol / L acetic acid solution dropwise to 1 g of nano-TiO with a particle size of 10-20 nm. 2 Grind the powder in a mortar until viscous, apply it on the conductive surface of the conductive glass substrate 1, bake at 130°C for 0.5 hours, soak in 0.3mmol / L photosensitive dye C106 (sonication for 20 minutes before use) for 12 hours, and dried to form a photoelectric conversion layer 2 with a thickness of 200 μm; add 1 mL of 0.15 mol / L acetic acid solution dropwise into a mortar containing 1 g of carbon airgel powder, grind until viscous, and apply On the side of the photoelectric conversion layer 2 away from the conductive glass substrate, bake at 130° C. for 0.5 hour to form a power storage layer 3 with a thickness of 400 μm; then coat the conductive glass substrate with the photoelectric conversion layer 2 and the power storage layer 3 1 Baking at 100°C for 1 hour to form the positive electrode of the energy storage photosensitive solar cell.

[0026] Th...

Embodiment 2

[0028] Add 1 mL of N-methylpyrrolidone dropwise to 1 g of nano-TiO with a particle size of 10-20 nm. 2 Grind the powder in a mortar until viscous, apply it on the conductive surface of the conductive glass substrate 1, bake at 130°C for 0.5 hours, soak in 0.3mmol / L photosensitive dye N719 (sonication for 20 minutes before use) for 14 hours, and dried to form a photoelectric conversion layer 2 with a thickness of 250 μm; 1 mL of N-methylpyrrolidone was added dropwise into a mortar containing 1 g of carbon airgel powder, ground until viscous, and coated on the photoelectric conversion layer 2. On the side of layer 2 away from the conductive glass substrate, bake at 130° C. for 0.5 hour to form a storage layer 3 with a thickness of 400 μm; then place the conductive glass substrate 1 coated with photoelectric conversion layer 2 and storage layer 3 at 100 Bake at ℃ for 1 hour to form the positive electrode of the energy storage photosensitive solar cell.

[0029] The thickness of ...

Embodiment 3

[0031] Add 1 mL of N-methylpyrrolidone dropwise to 1 g of nano-TiO with a particle size of 10-20 nm. 2 Grind the powder in a mortar until viscous, apply it on the conductive surface of the conductive glass substrate 1, bake at 130°C for 0.5 hours, soak in 0.3mmol / L photosensitive dye N3 (sonication for 20 minutes before use) for 16 hours, and dried to form a photoelectric conversion layer 2 with a thickness of 300 μm; 1 mL of N-methylpyrrolidone was added dropwise into a mortar containing 1 g of carbon airgel powder, ground until viscous, and coated on the photoelectric conversion layer 2. On the side of layer 2 away from the conductive glass substrate, bake at 130° C. for 0.5 hour to form a storage layer 3 with a thickness of 400 μm; then place the conductive glass substrate 1 coated with photoelectric conversion layer 2 and storage layer 3 at 100 Bake at ℃ for 1 hour to form the positive electrode of the energy storage photosensitive solar cell.

[0032] The thickness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com