A kind of molybdenum oxide/carbon coated titanium nitride nanotube array composite material and its preparation method and application

A nanotube array and titanium nanotube technology, applied in the field of electrochemical new energy and new materials, can solve the problems of poor charge-discharge cycle stability, unsatisfactory electrical conductivity, and unsatisfactory electrochemical corrosion resistance, so as to improve electrochemical resistance. Corrosion performance, improved electrochemical energy storage performance, good effect on charge and discharge cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

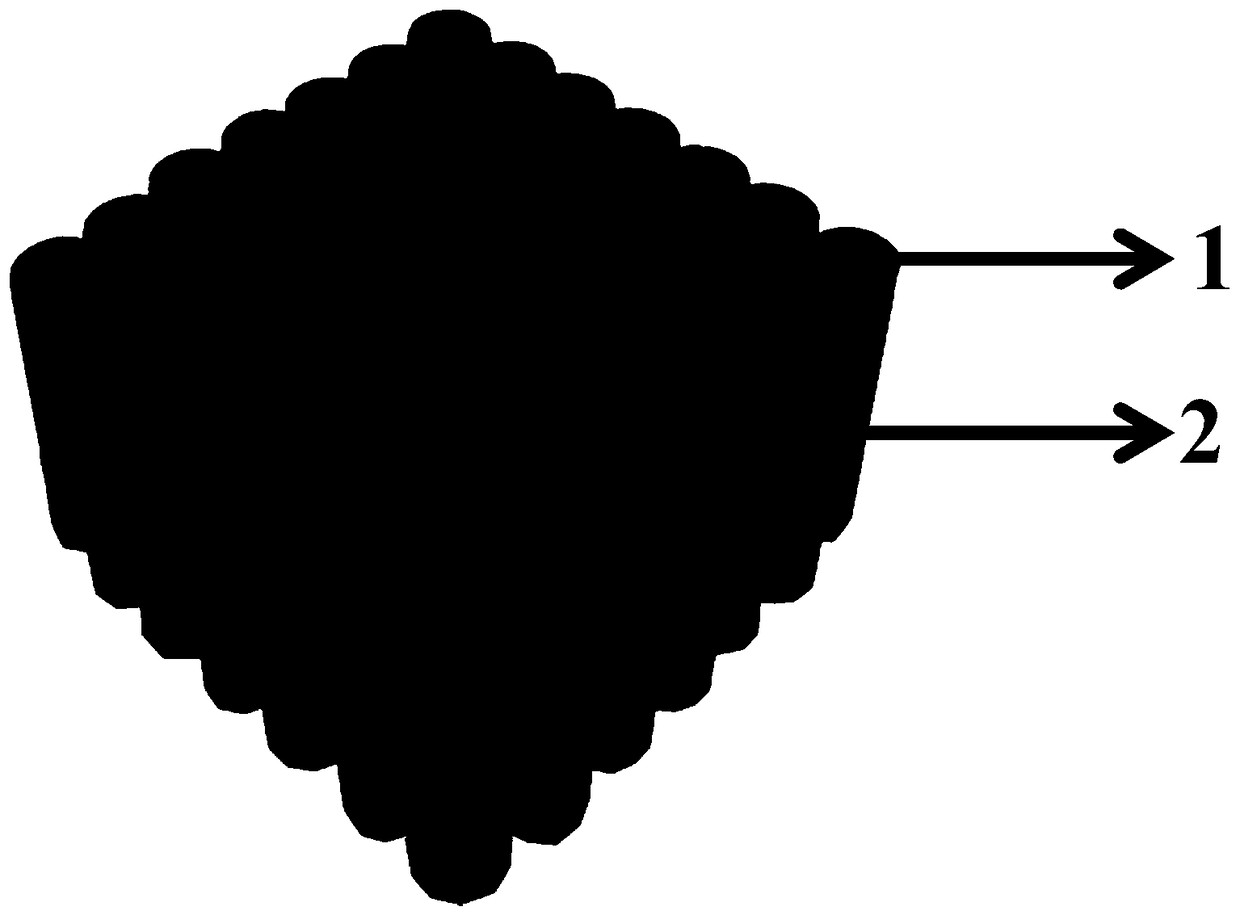

[0042] The structural schematic diagram of the molybdenum oxide / carbon coated titanium nitride nanotube array composite material described in the present invention is detailed in the appendix of the description. figure 1 . The molybdenum oxide / carbon-coated titanium nitride nanotube array composite material includes a molybdenum oxide nanofilm 1 and a carbon-coated titanium nitride nanotube array 2; The titanium nanotube array 2 serves as a conductive base layer, and the molybdenum oxide nanofilm 1 completely covers the surface of the carbon-coated titanium nitride nanotube array 2, forming an integrated molybdenum oxide / carbon-coated titanium nitride nanotube array composite material The molybdenum oxide nano-membrane 1 has a microporous membrane structure assembled from nanoparticles, and the carbon-coated titanium nitride nanotube array 2 has a nanotube array structure with tube walls connected and orderly and closely arranged.

[0043] Molybdenum oxide nano-membrane 1 is ...

Embodiment 2

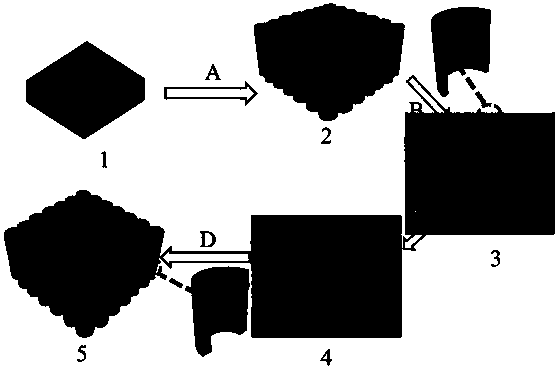

[0046] The preparation process flow chart of the molybdenum oxide / carbon-coated titanium nitride nanotube array composite material described in the present invention is detailed in the appendix of the specification figure 2 . Among them, (1) is a titanium sheet, (2) is a titanium dioxide nanotube array, (3) is a titanium nitride nanotube array, (4) is a carbon-coated titanium nitride nanotube array, and (5) is an oxide Molybdenum / carbon coated titanium nitride nanotube array; (A) anodic oxidation and calcination, (B) high temperature nitriding method, (C) organic carbon source carbonization method, (D) cyclic voltammetry electrochemical deposition method .

[0047] The specific preparation steps of molybdenum oxide / carbon coated titanium nitride nanotube array composite material are as follows:

[0048] (1) Titanium dioxide nanotube array material prepared by anodic oxidation and calcination method:

[0049] A two-electrode electrochemical reaction system was established, ...

Embodiment 3

[0057] The preparation method of molybdenum oxide / carbon coated titanium nitride nanotube array composite material.

[0058] (1) Titanium dioxide nanotube array material prepared by anodic oxidation and calcination method:

[0059] A two-electrode reaction system was established. The titanium sheet was chemically polished in nitric acid and hydrofluoric acid polishing solution for 10 seconds, fully washed with deionized water and dried. The prepared titanium sheet was used as the anode and the platinum sheet was used as the cathode. The mass percent concentration was 0.25 An ethylene glycol solution composed of % ammonium fluoride and 1% water by mass was used as the reaction electrolyte. Under the condition of 60V voltage and constant reaction temperature of 25°C, the titanium dioxide nanotube array was prepared by anodic oxidation reaction for 3 hours. Then, put the titania nanotube array into a muffle furnace for high-temperature calcination to perform crystal transformatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com