Method for preparing MnO2 nano array through normal-temperature two-electrode electrodeposition and product thereof

A nano-array and electrodeposition technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of high cost and complicated process, and achieve the effect of low cost, simple operation, and powerful effective surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of MnO by a two-electrode electrodeposition at room temperature 2 The method of nanometer array, its step is as follows:

[0028] First, dissolve 12.5505 g of Mn(NO 3 ) 2 4H 2 O solid adds a certain amount of deionized water and mixes to obtain 500ml0.1mol / L of Mn(NO 3 ) 2 aqueous solution; then, measure 8ml of Mn(NO 3 ) 2 The aqueous solution was mixed with 72ml deionized water and stirred to obtain 80ml 0.01mol / L of Mn(NO 3 ) 2 solution, pour it into the electrolytic tank, use carbon fiber as the positive and negative electrodes for electrolysis, and apply a voltage of 9V (positive and negative electrode voltage) to electrolyze it for 20 minutes; then use deionized water and absolute ethanol to alternately wash the negative electrode for 60 minutes; Dry at 100°C for 4h to get MnO deposited on the surface 2 Nanoarrays of carbon fibers.

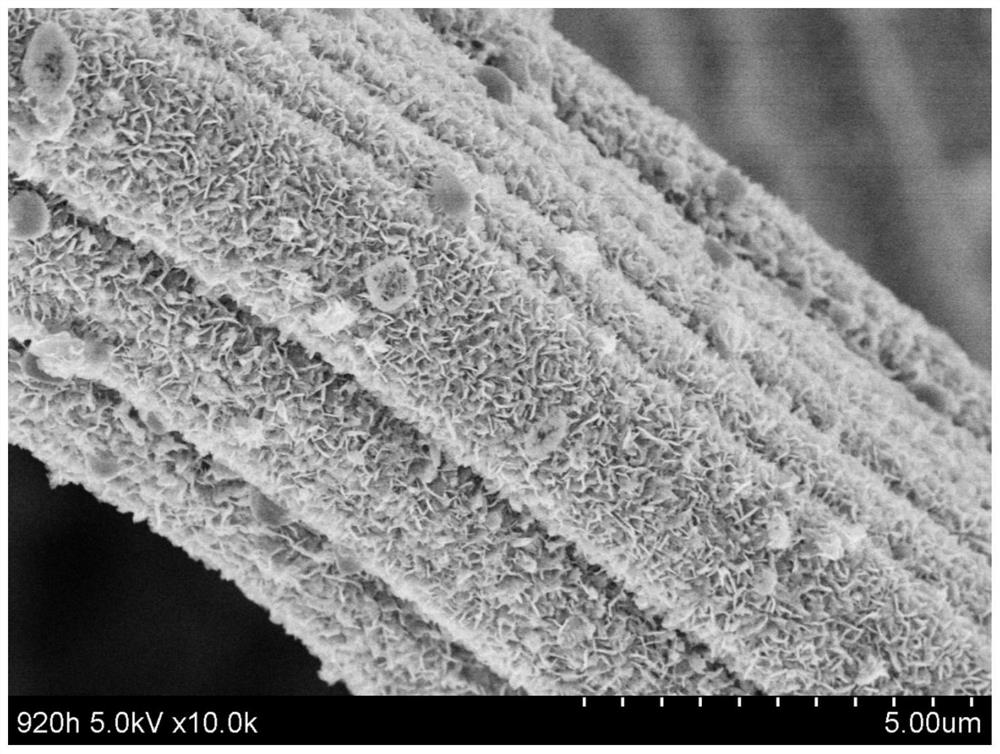

[0029] The prepared surface was deposited with MnO 2 SEM images of carbon fibers in nanoarrays such as figure...

Embodiment 2

[0041] Preparation of MnO by a two-electrode electrodeposition at room temperature 2 The method of nanometer array, its step is as follows:

[0042] First, dissolve 12.5505 g of Mn(NO 3 ) 2 4H 2 O solid adds a certain amount of deionized water and mixes to obtain 500ml0.1mol / L of Mn(NO 3 ) 2 aqueous solution; then measure 16ml of Mn(NO 3 ) 2 The aqueous solution was mixed with 64ml deionized water and stirred to obtain 80ml 0.02mol / L of Mn(NO 3 ) 2 Solution, pour it into the electrolytic tank, use carbon fiber as the positive and negative electrodes for electrolysis, apply 12V voltage (positive and negative electrode voltage) to electrolyze it for 40min; then use deionized water and absolute ethanol to wash the negative electrode alternately for 10min; finally in Dry at 80°C for 2h to get MnO deposited on the surface 2 Nanoarrays of carbon fibers.

Embodiment 3

[0044] Preparation of MnO by a two-electrode electrodeposition at room temperature 2 The method of nanometer array, its step is as follows:

[0045] First, dissolve 12.5505 g of Mn(NO 3 ) 2 4H 2 O solid adds a certain amount of deionized water and mixes to obtain 500ml0.1mol / L of Mn(NO 3 ) 2 aqueous solution; then measure 8ml of Mn(NO 3 ) 2 Mix and stir the aqueous solution with 64ml deionized water and 8ml DMSO to obtain 80ml 0.01mol / L Mn(NO 3 ) 2 Solution, pour it into the electrolytic tank, use carbon fiber as the positive and negative electrodes for electrolysis, apply 9V voltage (positive and negative electrode voltage) to electrolyze it for 30min; then use deionized water and absolute ethanol to wash the negative electrode alternately for 1min; finally in Dry at 100°C for 4h to get MnO deposited on the surface 2 Nanoarrays of carbon fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com