Method for preparing activated carbon/nano-platinum/polyaniline composite material from corn stalks

A technology for preparing activated carbon and corn stalks, applied in chemical instruments and methods, carbon compounds, hybrid capacitor electrodes, etc., can solve problems such as environmental pollution and resource waste, achieve the effects of reducing environmental pollution, low cost, and broadening energy channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

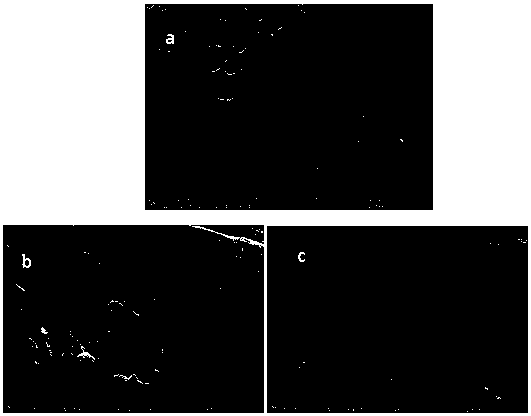

Image

Examples

Embodiment 1

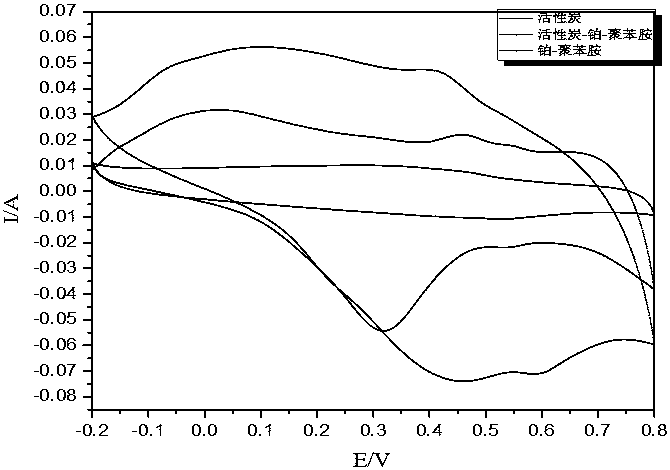

[0015] Example 1: Synthesize activated carbon / nano-platinum / polyaniline according to the following steps (activated carbon:aniline=1:5)

[0016] (1) Soak 4.0g of corn stalks crushed to 50 meshes in 32.0mL of phosphoric acid solution with a mass concentration of 18%, soak for 50min at 80°C, and then activate in a microwave oven with a power of 700W for 3min to obtain a high specific surface area activated carbon (C);

[0017] (2) Take 2.0 g of the activated carbon prepared in step (1), heat it in 30.0 mL of 6mol / L nitric acid at 60°C for 4 hours at a constant temperature in a water bath, centrifuge, wash with water until neutral, and dry to obtain activated activated carbon;

[0018] (3) Take 0.4g of the acid-treated activated carbon in step (2), add 0.38g of citric acid and 5.2mL of ethylene glycol solution containing 0.2M NaOH, inject 1.0mL of 0.04mol / L chloroplatinic acid, and heat to reflux for 1.5h. The product is centrifuged, washed, and dried to obtain activated carbon / ...

Embodiment 2

[0020] Example 2: Synthesize activated carbon / nano-platinum / polyaniline according to the following steps (activated carbon:aniline=1:20)

[0021] (1) Soak 8 g of corn stalks crushed to 50 mesh in 64 mL of phosphoric acid solution with a mass concentration of 18%, soak for 50 min at 80°C, and then activate in a microwave oven with a power of 700W for 3 min to obtain a high specific surface area Activated carbon (C);

[0022] (2) Take 4g of the activated carbon prepared in step (1), heat it in 40mL of 6mol / L nitric acid in a water bath at 60°C for 4 hours, centrifuge, wash with water until neutral, and dry to obtain activated activated carbon;

[0023] (3) Take 0.4g of activated carbon after step (2), 1.9g of citric acid, 26mL of 0.2mol / L sodium hydroxide in ethylene glycol, and 5mL of 0.04mol / L chloroplatinic acid solution in a round bottom flask , heated to reflux for 2 hours, and the product was centrifugally washed and dried to obtain a composite material of activated carbo...

Embodiment 3

[0025] Example 3: Synthesize activated carbon / nano-platinum / polyaniline according to the following steps (activated carbon:aniline=1:10)

[0026] (1) Soak 4.0g of corn stalks crushed to 50 meshes in 32.0mL of phosphoric acid solution with a mass concentration of 18%, soak for 50min at 80°C, and then activate in a microwave oven with a power of 700W for 3min to obtain a high specific surface area activated carbon (C);

[0027] (2) Take 2.0 g of activated carbon prepared in step (1), heat it in 60.0 mL of 6mol / L nitric acid at 60°C for 4 hours at a constant temperature in a water bath, centrifuge, wash with water until neutral, and dry to obtain activated activated carbon;

[0028] (3) Take 0.4g of the acid-treated activated carbon in step (2), add an appropriate amount of 0.76g of citric acid and 10.4mL of ethylene glycol solution containing 0.2M NaOH, inject 2.0mL of 0.04mol / L chloroplatinic acid, and heat to reflux for 1.5h , the product was centrifuged, washed, and dried to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com