Method employing temperature compensation to stabilize LED lamp temperature

A technology of temperature compensation and LED lamps, which is applied in the layout of electric lamp circuits, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problems that the influence of ambient temperature on the temperature rise of LED lamps cannot be changed, and the cooling range is limited, etc., to achieve Reduce the luminous flux, avoid shortening the service life, and prolong the effect of LED life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further elaborated below through specific embodiments. Examples will help to better understand the present invention, but the present invention is not limited only to the following examples.

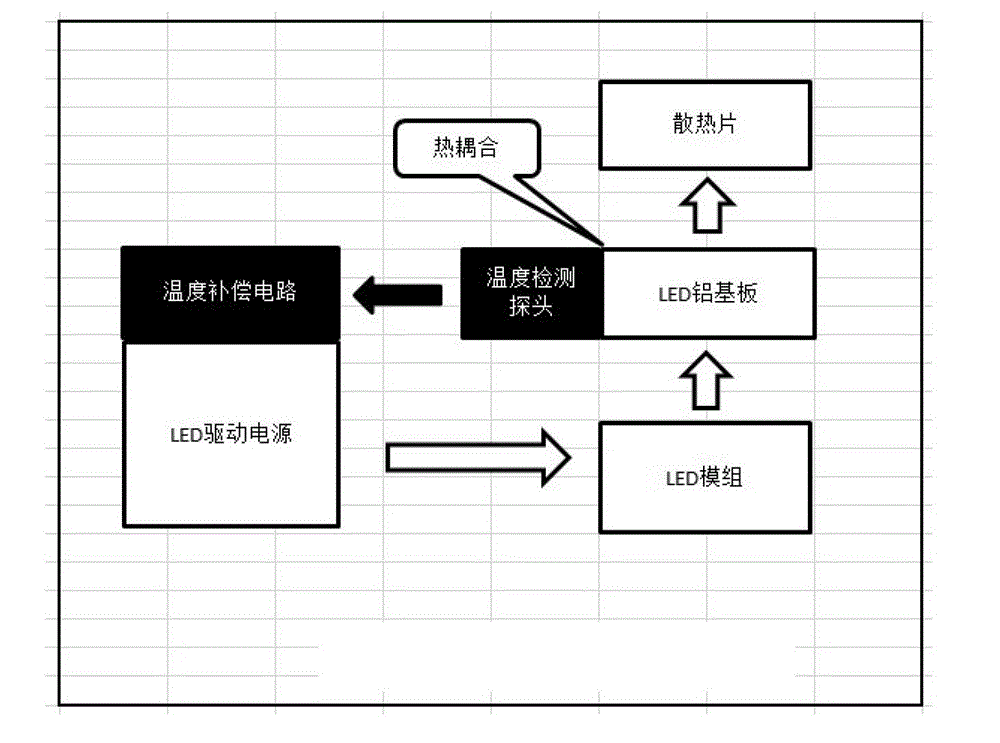

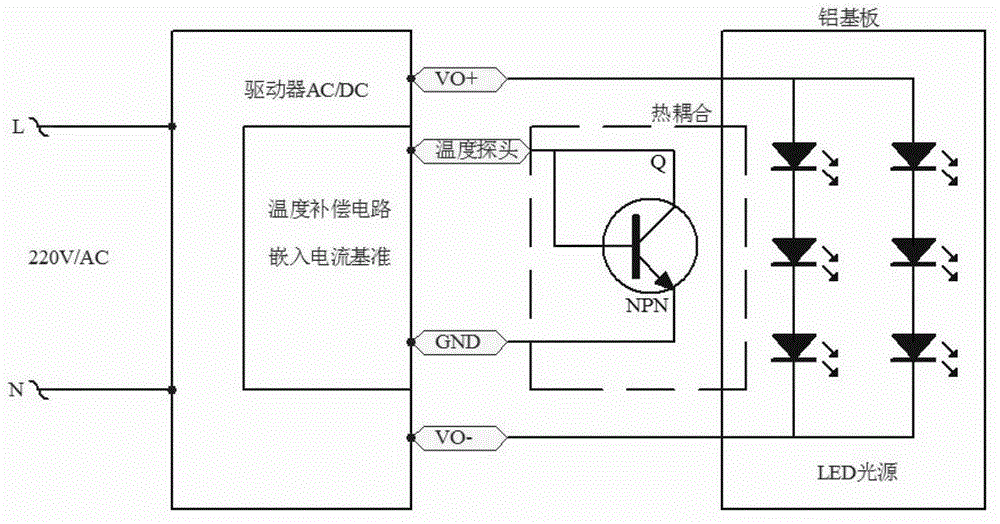

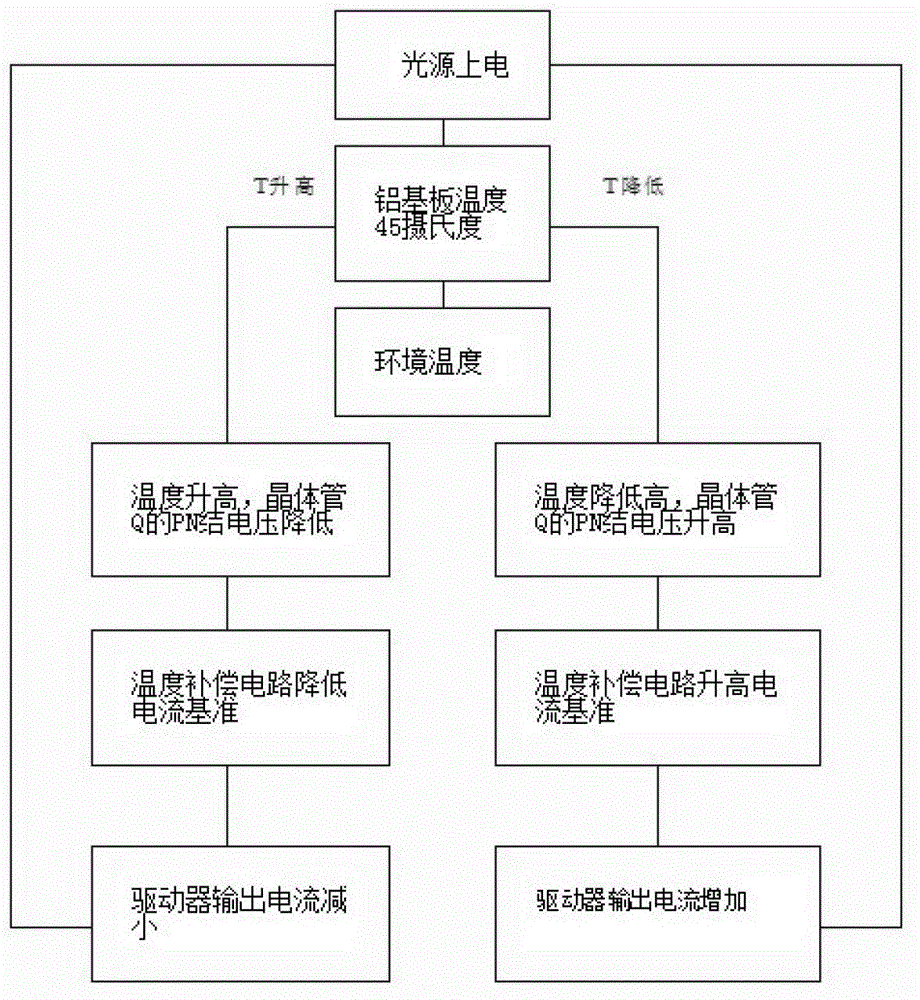

[0014] High-power LED lamps generally work in a constant current state. When the external environment temperature changes, the LED forward voltage decreases, and the LED drive power supply reduces the output voltage accordingly, basically maintaining the output current and output power constant. The invention utilizes the temperature compensation technology to monitor the temperature of the LED lamp, and feeds back to the LED driving power supply in real time for current regulation. When the temperature is high, the temperature compensation system reduces the output current to achieve the purpose of limiting and reducing the temperature rise; when the temperature decreases, the temperature compensation system increases the output current appropriately,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com