Ultra-narrow row rotary tillage and fertilization integrated type wheat high-yield seeding machine

An ultra-narrow, integrated technology, applied in the field of agricultural farming machinery, can solve the problems of high soil moisture loss, many production processes, damage to agricultural ecological resources, etc., to solve the congestion of fertilization and sowing operations, reduce labor and material resources, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

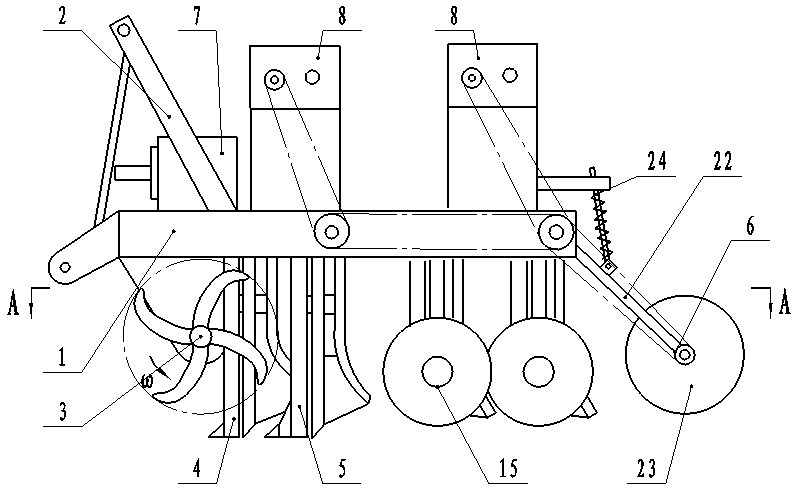

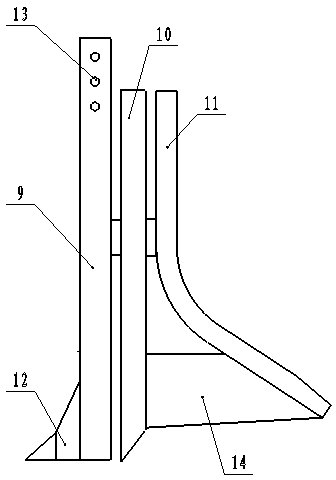

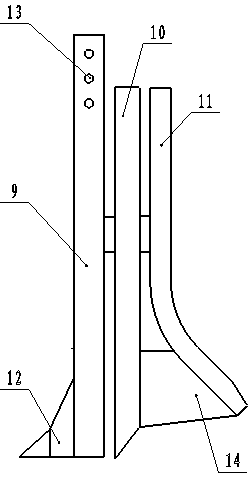

[0034] like Figure 1-6 As shown in the figure, the ultra-narrow row rotary tillage and fertilization integrated wheat high-yield seeder of the present invention includes a frame 1, a hanger 2, a rotary tillage mechanism 3, an arrow-type fertilization and sowing trenching mechanism, a double-disc fertilizing and sowing trenching mechanism, and a repression mechanism. The mechanism 6 and the fertilizing and seeding box 8, the suspension frame 2 is fixedly installed above the front end of the frame 1, the rotary tillage mechanism 3 is installed below the front end of the frame 1, and the arrow type is installed in order from front to back at the bottom of the middle of the frame 1. The fertilization and seeding ditching mechanism and the double-disc fertilization and sowing ditching mechanism, the arrow-type fertilization and sowing ditching mechanism and the double-disc fertilization and seeding ditching mechanism are both equipped with a fertilization and seeding box 8 and two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com