Cold ring rolling forming process for asymmetric shape of hub bearing outer ring and closed cold rolling forming die

A technology of wheel hub bearing and forming process, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of poor process design, unreasonable, inability to stabilize the cold rolling expansion of finished products, etc., and achieve reasonable internal metal streamlines. , easy to process, ensure long life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical process of the present invention will be further described below in conjunction with the accompanying drawings, but it cannot be construed as a limitation of the present invention, and the remaining unexplained parts of the present invention are consistent with the prior art.

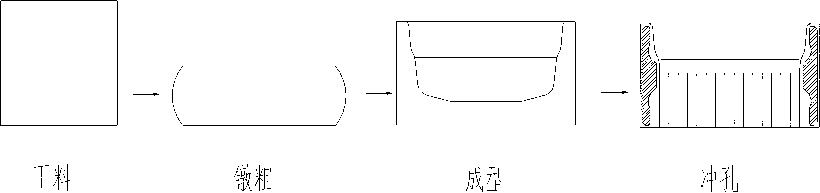

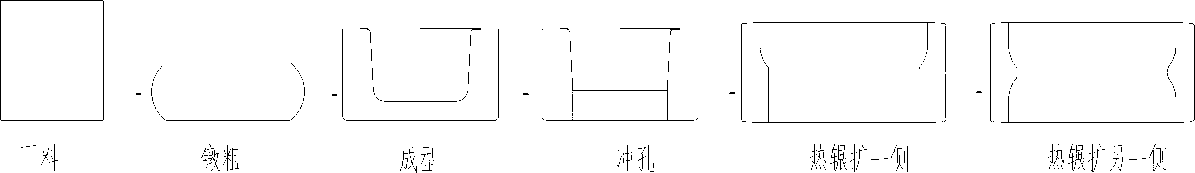

[0034] refer to Figure 3~Figure 5 As mentioned above, the asymmetric shape cold rolling and expanding forming process of the wheel hub bearing outer ring according to the present invention includes the following steps:

[0035] Step 1) Blanking: Get the weight of the blanking according to the size of the forged part, and then select a suitable bar according to the length-to-diameter ratio of 0.8-1.2, and then obtain the blanking size. In the embodiment, the diameter of the bar is 45mm and the length is 50mm;

[0036] Step 2) Upsetting: The upsetting diameter can be obtained by subtracting 1 mm from the maximum outer diameter of the forged part, and then the upsetting thickness can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com