High-speed main shaft cooling device

A technology of cooling device and high-speed spindle, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problem of unsatisfactory cooling effect, achieve good cooling effect, improve service life, and prevent damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

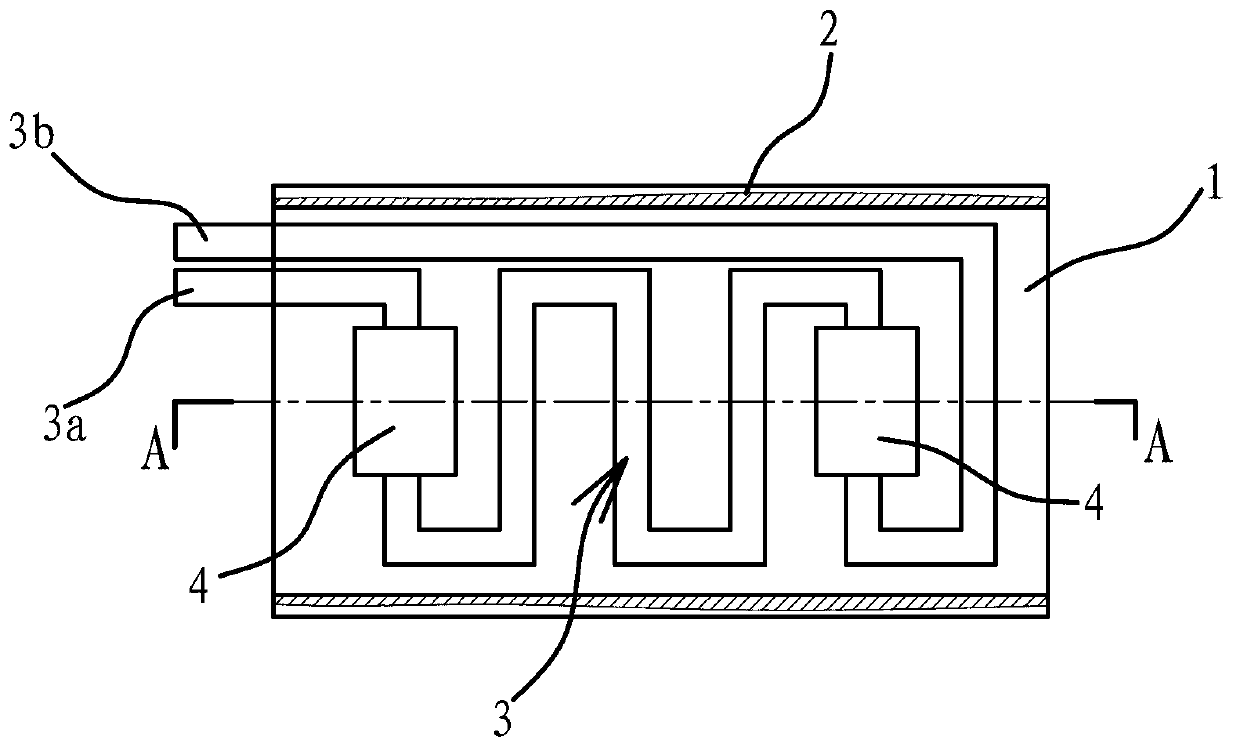

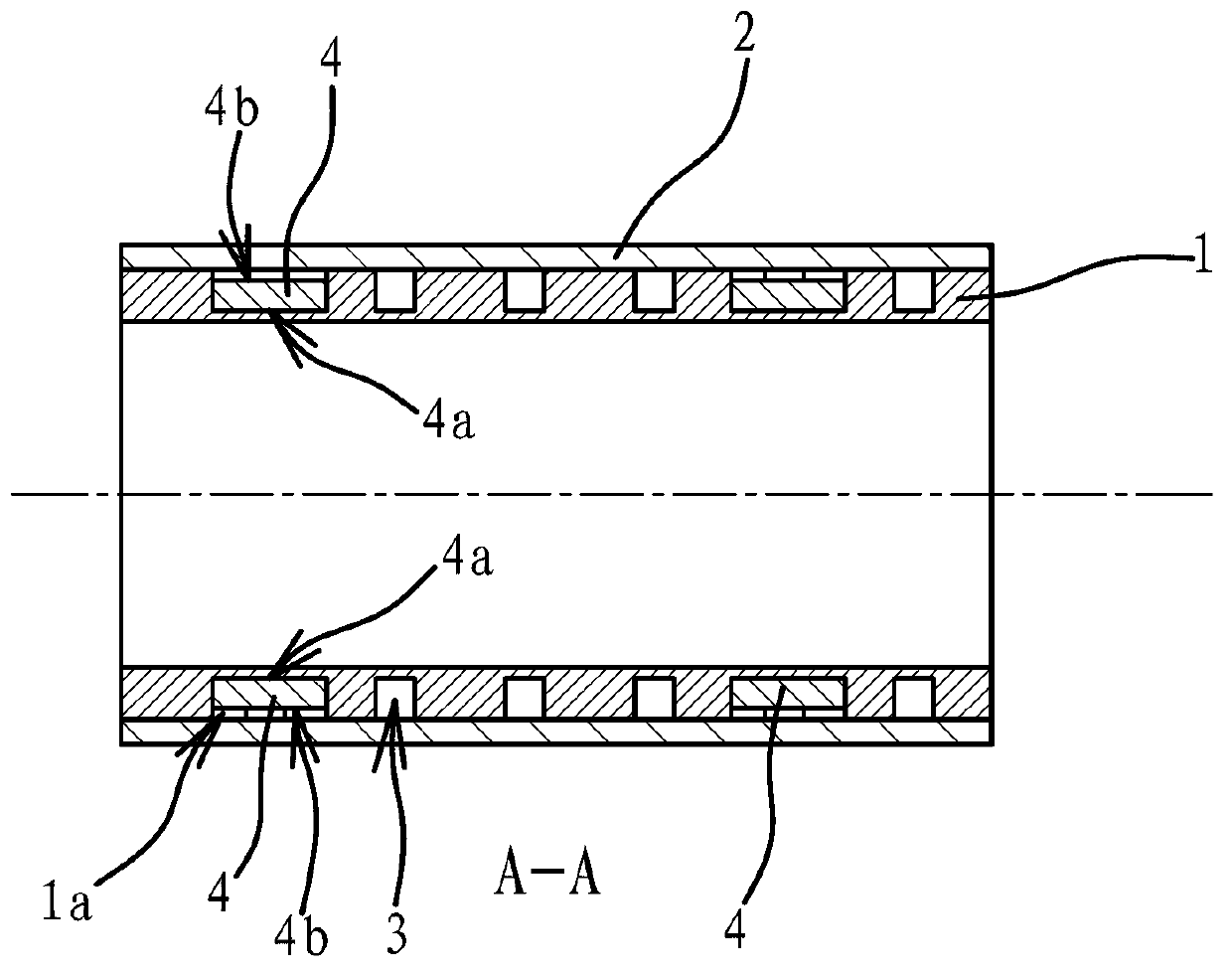

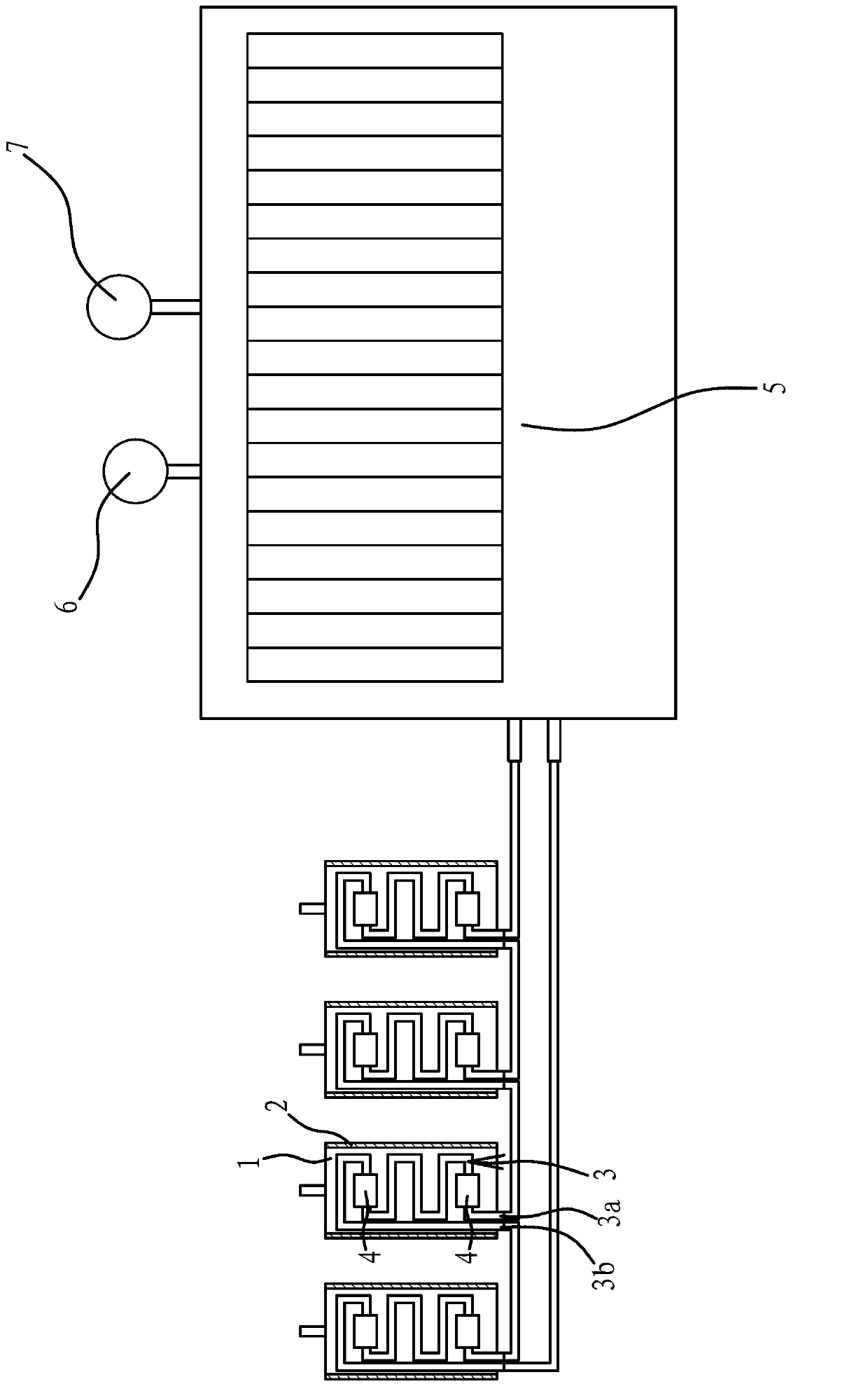

Image

Examples

Embodiment 2

[0036] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 4 As shown, the semiconductive cooling sheet 4 is arc-shaped, and the arc of the semiconducting cooling sheet 4 matches the arc surface of the outer wall of the inner tube 1 . The semiconductor refrigerating sheet 4 is arc-shaped and the arc surface of the outer wall of the inner cylinder 1 matches, so that the semiconductor refrigerating sheet 4 and the outer wall of the inner cylinder 1 can be closely attached, and has the advantage of better heat dissipation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com