Novel double-printing-head UV flatbed printer

A flatbed printer and dual-nozzle technology, applied in printing and other directions, can solve the problems of troublesome cleaning method and complicated operation, and achieve the effect of simple structure and prolonged use time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

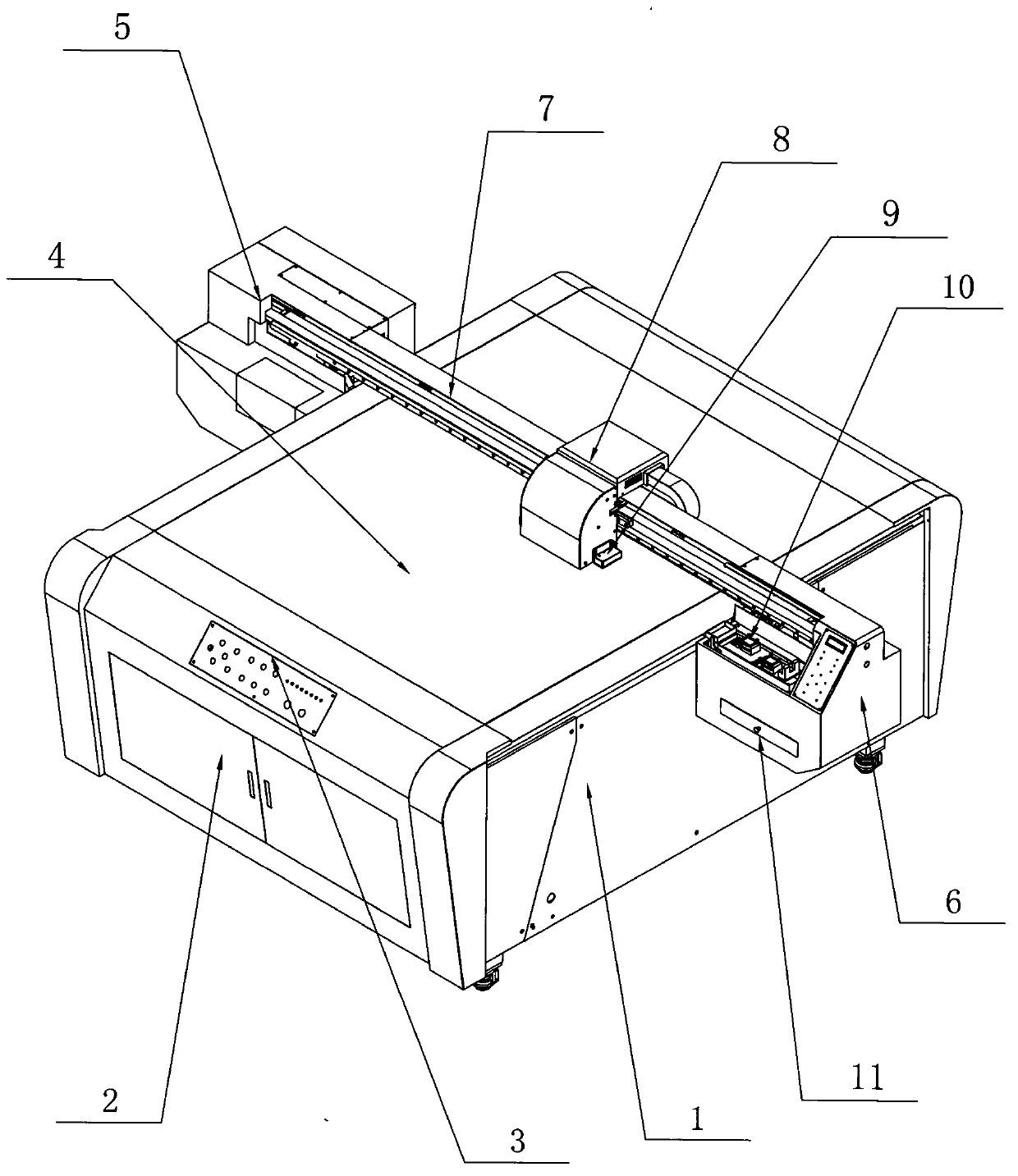

[0010] see figure 1 , the specific embodiment adopts the following technical solutions: it includes a printer body 1, a power distribution box 2, a control panel 3, a printing platform 4, an ink supply device 5, a waste ink collection device 6, a connecting beam 7, an inkjet print head 8, LED water-cooled UV curing lamp 9, ink absorbing cup 10, waste ink drawer 11, the front end of the printer body 1 is provided with a distribution box 2, the upper end of the distribution box 2 is provided with a control panel 3, the upper surface of the printer body 1 A printing platform 4 is provided, an ink supply device 5 is provided on the left side of the printer body 1, a waste ink collection device 6 is provided on the right side of the printer body 1, and a connecting beam 7 is connected between the ink supply device 5 and the waste ink collection device 6 An inkjet printing head 8 is arranged in the middle of the connecting beam 7, an LED water-cooled UV curing lamp 9 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com