C/ZrC composite material prepared on basis of vapor infiltration reaction, preparation method thereof and equipment for process

A composite material and process technology, which is applied in the field of preparation of ultra-high temperature thermal protection structures, can solve the problem that the product structure uniformity and performance consistency cannot be guaranteed, it is difficult to control the reaction time, the degree of internal penetration of the reaction volume, and the impact on the high temperature of the composite material. Stability and mechanical properties and other issues, to achieve the effect of increasing effective evaporation, excellent performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A C / ZrC composite material prepared based on vapor phase infiltration reaction of the present invention, the C / ZrC composite material is based on zirconium carbide, and carbon fiber prefabricated body is used as a reinforcing phase, and the reinforcing phase in this embodiment has a volume fraction of about 15% three-dimensional needle felt, the density of the C / ZrC composite is 4.12g / cm 3 , the porosity is 15%, and the content of metal zirconium in the C / ZrC composite material is 0.1wt%. The measurement method of the residual metal Zr is: cut the C / ZrC composite material into 3mm×3mm×5mm blocks, and weigh them after ultrasonic cleaning and drying with ethanol. 1 , soaked in 10% acid solution (HCl:HF=3:1) for 12h, then took out distilled water and ultrasonically cleaned several times, dried and weighed m 2 , the residual metal Zr content is obtained as (m 1 -m 2 ) / m 1 .

[0038] The preparation method of the above-mentioned C / ZrC composite material of the present e...

Embodiment 2

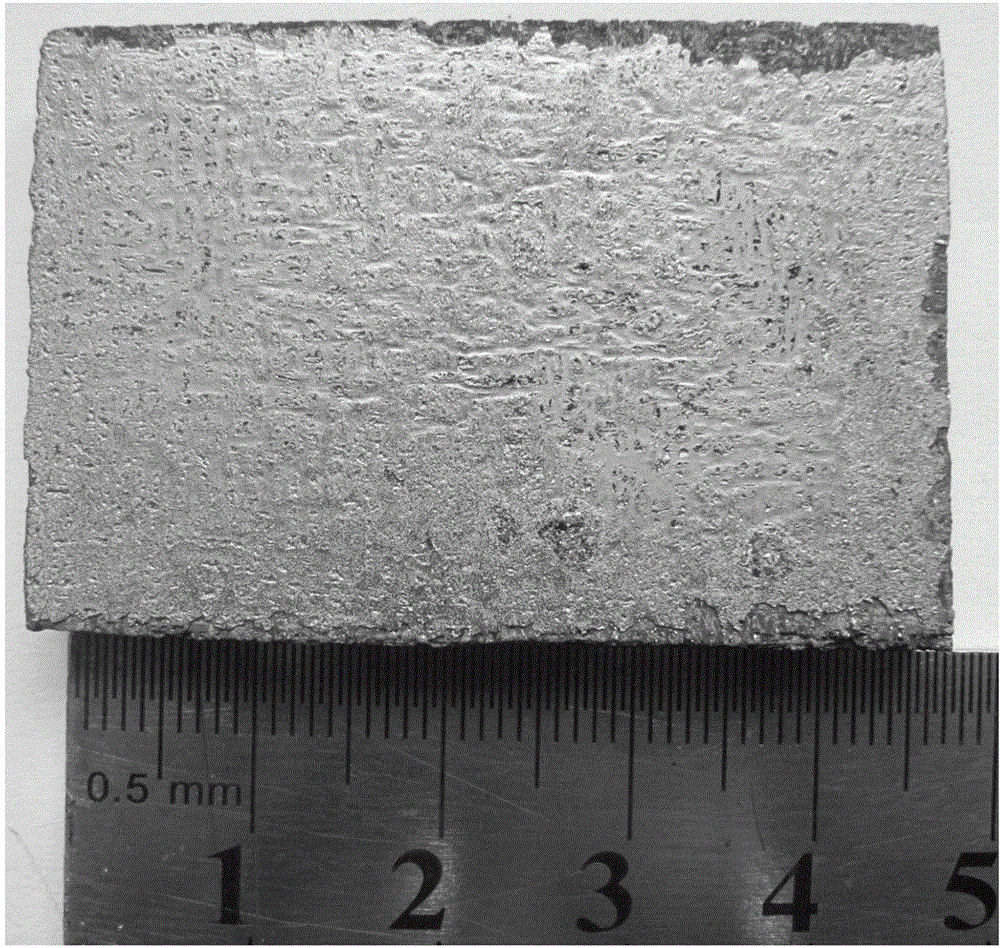

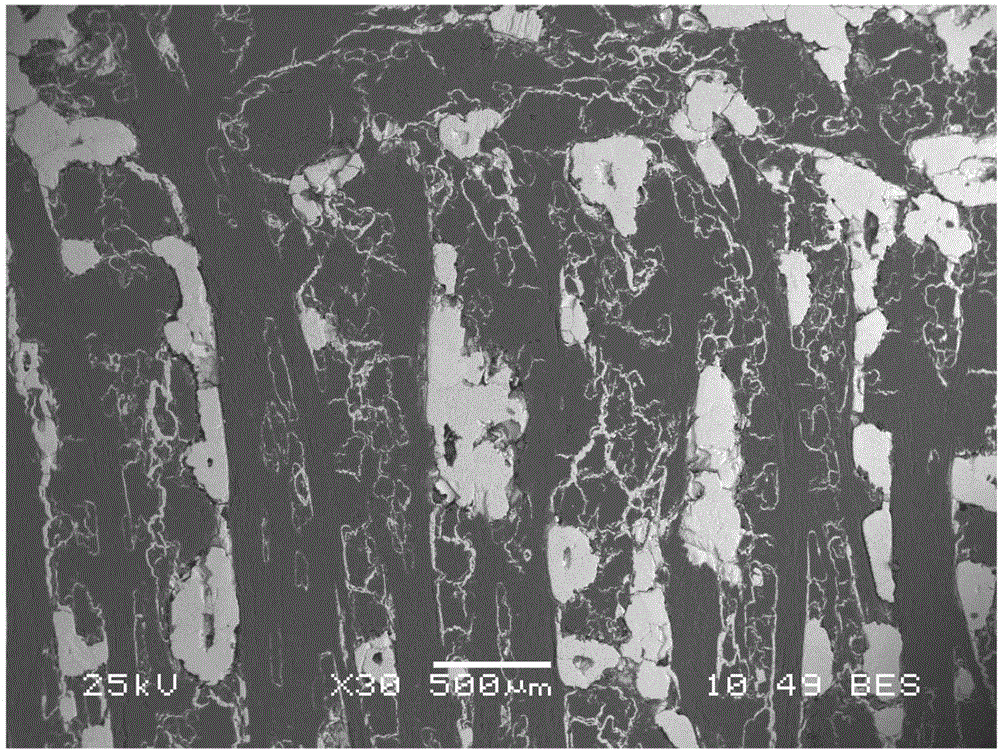

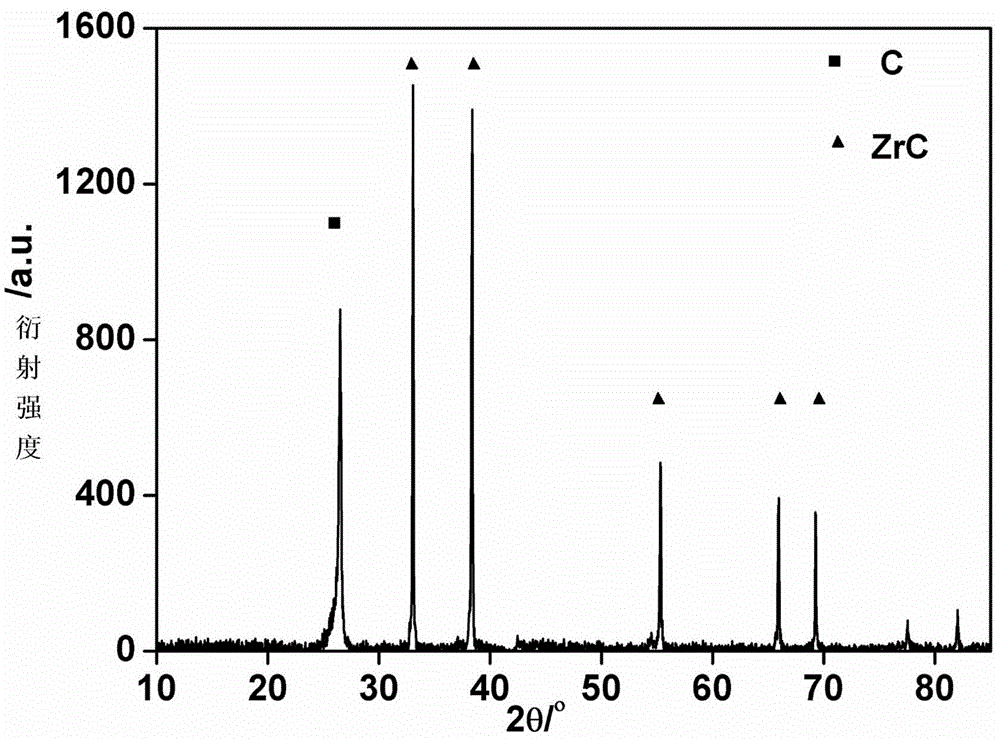

[0046] a kind of like figure 2 , image 3 The C / ZrC composite material prepared based on the vapor phase infiltration reaction of the present invention is shown. The C / ZrC composite material uses zirconium carbide as the matrix and carbon fiber prefabricated body as the reinforcing phase. The reinforcing phase in this embodiment has a volume fraction of about 15% three-dimensional needle felt, the density of the C / ZrC composite is 3.07g / cm 3 , the porosity is 13%, and the content of metal zirconium in the C / ZrC composite material is 0.5wt%.

[0047] The preparation method of the above-mentioned C / ZrC composite material of the present embodiment specifically comprises the following steps:

[0048] (1) Forming of fiber prefabricated body: the continuous fiber cloth and short fibers are arranged and three-dimensionally needled to obtain a carbon fiber prefabricated body; the volume fraction of the carbon fiber prefabricated body is 15%;

[0049] (2) Preparation of fiber prote...

Embodiment 3

[0056] A C / ZrC composite material prepared based on gas phase infiltration reaction of the present invention, the C / ZrC composite material is based on zirconium carbide, and carbon fiber prefabricated body is used as a reinforcing phase. The reinforcing phase in this embodiment has a volume fraction of about 45% three-dimensional punctured fiber cloth, the density of the C / ZrC composite is 2.75g / cm 3 , the porosity is 8%, and the content of metal zirconium in the C / ZrC composite material is 0.2wt%.

[0057] The preparation method of the above-mentioned C / ZrC composite material of the present embodiment specifically comprises the following steps:

[0058] (1) Forming of fiber prefabricated body: the carbon cloth is laminated and punctured in the Z direction to obtain a carbon fiber prefabricated body; the volume fraction of the carbon fiber prefabricated body is 45%;

[0059] (2) Preparation of fiber protective coating: A cracked carbon coating was deposited on the fiber surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com