Method for forming aluminum silicon carbide substrate for high-power module

An aluminum silicon carbide-based and silicon carbide-based technology is applied in the field of forming aluminum silicon carbide substrates, which can solve the problems of high processing costs, difficulties in preparing aluminum silicon carbide substrates, and low forming costs, and achieve improved compactness, low expansion, and The effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

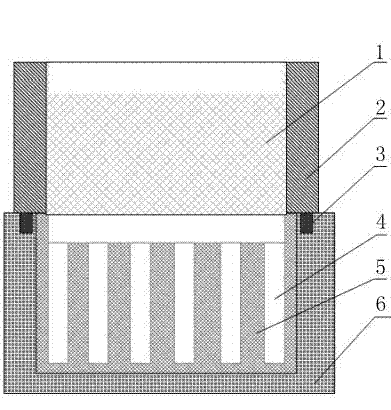

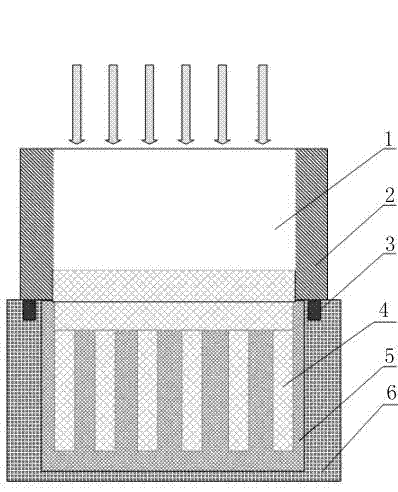

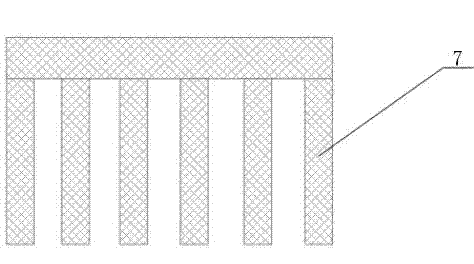

[0036] Use investment casting technology to prepare a mold shell 5 for aluminum silicon carbide substrates of a certain shape, put silicon carbide powder into the mold shell 5, compact the silicon carbide powder through two-dimensional mechanical vibration, and preheat the mold shell 5 to 800 After ℃, the aluminum alloy melt 1 is poured in, filled and solidified under hydraulic pressure, and the mold shell 5 is removed to obtain the aluminum silicon carbide substrate 7 . The surface roughness and appearance dimensions of the prepared aluminum silicon carbide substrate 7 were measured, and the surface roughness was Ra1.6, and the size deviation was ±0.05mm.

Embodiment 2

[0038] Use the shell casting technology to prepare a mold shell 5 for aluminum silicon carbide substrates of a certain shape, put the silicon carbide powder into the mold shell 5, compact the silicon carbide powder through three-dimensional mechanical vibration, and fill the gypsum into the sand box 6 before loading Fix the mold shell 5 and assemble it with the mold 2. After the mold shell 5 is preheated to 600°C, pour the aluminum alloy melt 1 and let it fill and solidify under the action of air pressure. Remove the mold shell 5 to obtain aluminum carbonization. Silicon substrate 7. The surface roughness and appearance dimensions of the prepared aluminum silicon carbide substrate 7 were measured, and the surface roughness was R3.2, and the size deviation was ±0.1mm.

Embodiment 3

[0040] Use investment casting technology to prepare a mold shell 5 for aluminum silicon carbide substrates of a certain shape, put silicon carbide powder into the mold shell 5, compact the silicon carbide powder by ultrasonic vibration, and fill the mullite into the sand box 6 Fix the mold shell 5 and assemble it with the mold 2. After the mold shell 5 is preheated to 400°C, pour the aluminum alloy melt 1 and let it be filled and solidified under hydraulic pressure. Remove the mold shell 5 to obtain aluminum alloy. Silicon carbide substrate 7 . The surface roughness and appearance dimensions of the prepared aluminum silicon carbide substrate 7 were measured, and the surface roughness was Ra1.6, and the size deviation was ±0.1mm.

[0041] The invention utilizes the molding shell forming technology, and the aluminum silicon carbide substrate whose surface quality and size meet product requirements has low manufacturing cost, convenient processing and no waste of resources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com