Method for manufacturing superplastic forming ceramic thin-wall product

A technology for superplastic molding and thin-walled products, which is applied in the field of thin-walled product manufacturing, can solve problems such as gas sealing difficulties, and achieve the effects of increased production efficiency, low efficiency, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

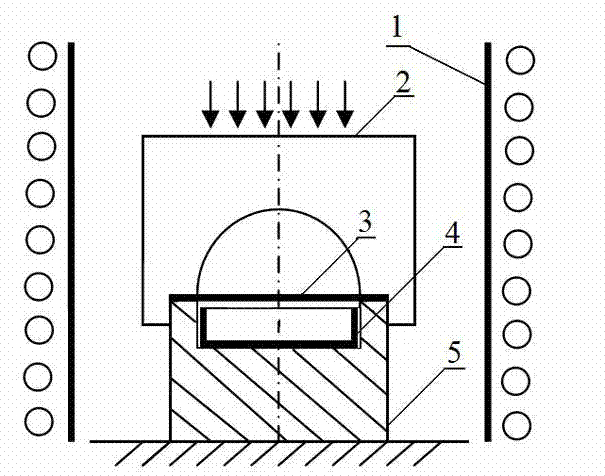

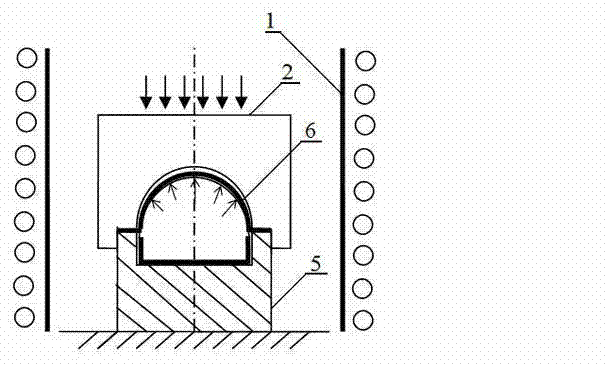

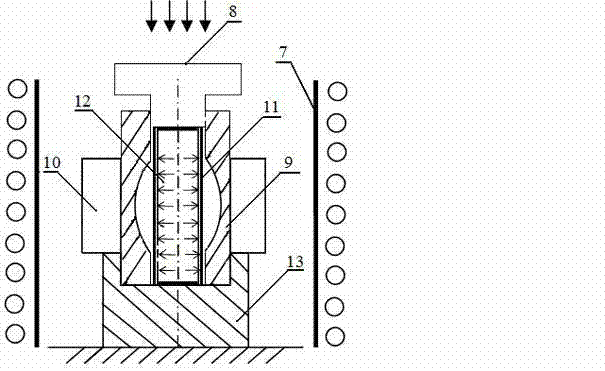

[0010] Embodiment 1: The manufacturing method of superplastic molded ceramic thin-walled products in this embodiment is as follows: 1. Put the gasification agent into a container made of superplastic titanium alloy, and then seal the container to form an air bag; 2. Put the air bag Put it into the groove in the lower mold, then cover the upper surface of the groove of the lower mold with a superplastic ceramic circular thin plate with a thickness of 2mm to 6mm, and then place the upper mold on the lower mold to obtain the workpiece; 3. Put the workpiece Put it into a vacuum hot-pressing sintering furnace, and keep it warm for 10-30 minutes under the condition that the upper surface pressure of the workpiece is 1MPa-10MPa and the temperature is 800-1000℃; 4. The upper surface pressure of the workpiece processed in step 3 is 15MPa ~30MPa, temperature 1400℃~1700℃ under the condition of heat preservation for 30~90 minutes, then cooling to room temperature, demoulding, and then mach...

specific Embodiment approach 2

[0011] Embodiment 2: This embodiment differs from Embodiment 1 in that the superplastic molded ceramic thin-walled product is a superplastic molded ceramic hemispherical product. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2, the superplastic ceramic circular thin plate is a composite ceramic circular thin plate mixed with ultra-fine grained zirconia and ultra-fine grained alumina. Fine-grain zirconia ceramic round sheet or ultra-fine-grain alumina ceramic round sheet. Others are the same as those in the first or second embodiment.

[0013] In this embodiment, in the multi-phase ceramic circular thin plate mixed with ultrafine grain zirconia and ultrafine grain alumina, the ratio of ultrafine grain zirconia to ultrafine grain alumina is arbitrary.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com