Whole-process monitoring waste cooking oil recovery system

A recovery system and technology of waste oil, which is applied in the direction of fat material recovery, oil/fatty acid recovery from waste, recycling technology, etc., can solve the problem of unscrupulous merchants, lack of scientific and technological content, catering waste oil recovery system, recycling waste Problems such as oil flow direction and use supervision are weak, so as to achieve the effect of easy promotion, convenient use and controllable supervision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

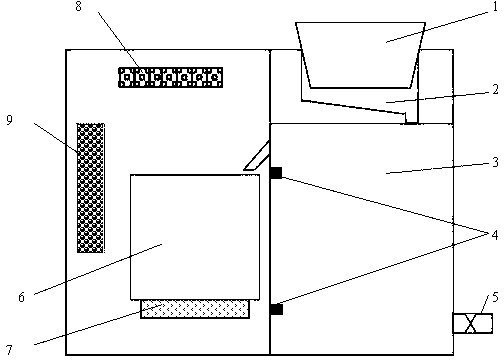

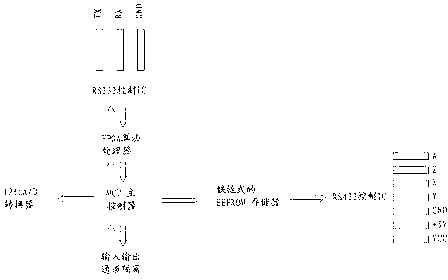

[0013] A whole-process monitoring and recycling system for catering waste oil and fat is composed of a working station, N workstations and other associated hardware and monitoring software systems. Its function is to separate and recycle waste catering oil, and to effectively monitor and manage the whole recycling process.

[0014] Below we give a detailed introduction to each part of the system:

[0015] A. Workstation The workstation is the station for food waste processing and information recording in the system, and it consists of two parts: oil storage type oil-water separator and electric control device.

[0016] There is a filter residue net 1 on the oil storage type oil-water separator, which leads to the feed tank 2 of the oil-water separation mechanism 3. On one side of the oil-water separation mechanism 3, there are upper and lower liquid level sensors 4, waste water outlet 5, and oil-water separation. The other side of mechanism 3 is placed with recovered oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com