Powerful pressing method and apparatus for disk spring

The technology of a disc spring and a return spring is applied in the field of spring strong pressing methods and devices, which can solve the problems of affecting production efficiency, disc springs flying out and hurting people, low work efficiency, etc., so as to improve efficiency and safety guarantee and improve safety performance, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order for those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

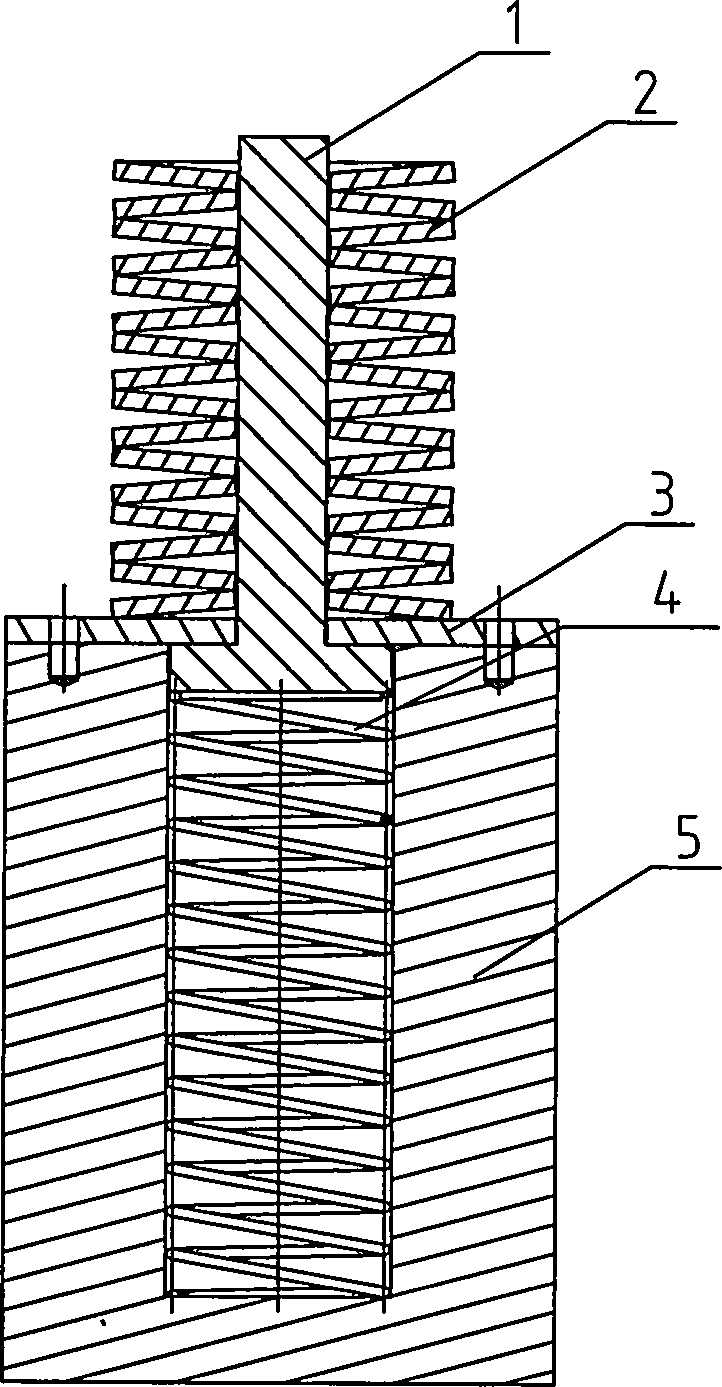

[0017] see figure 1 As shown, the disk spring group of the pressure device of the disk spring of the present invention is formed by stacking several disk springs 2 in opposite directions, and also includes a guide rod 1, an upper pressing plate 3, a return spring 4, and a base 5 , the return spring 4 is placed in the base 5, the upper part of the guide rod 1 passes through the disc spring group and is placed on the return spring 4, and the upper pressing plate 3 is fixedly connected with the base 5 by screws; by setting the guide rod 1, the The disc springs 2 stacked on each other are connected in series, and radially positioned through the cooperation of the upper outer diameter of the guide rod 1 and the inner diameter of the spring group, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com