Digital intelligent drilling fuel tank

A fuel tank and drilling technology, applied in the field of digital intelligent drilling fuel tank, can solve the problems of large measurement error, fuel theft, abnormal consumption, etc., and achieve the effect of convenient use and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

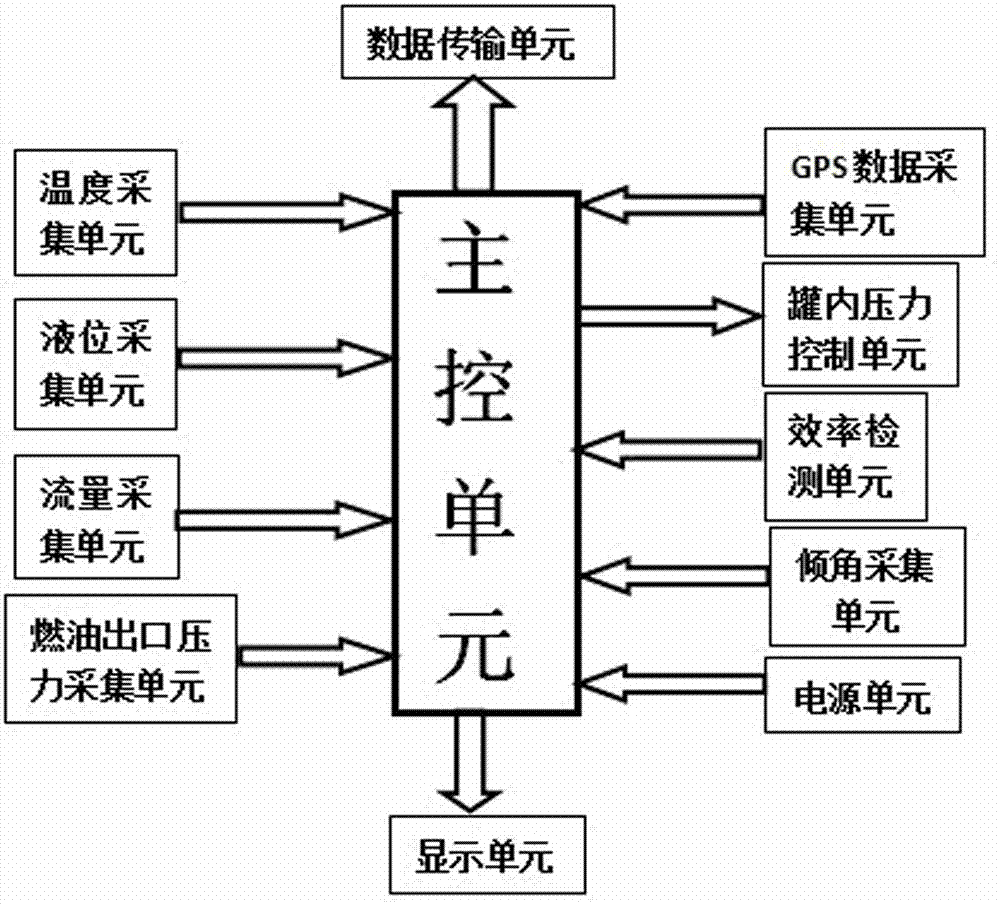

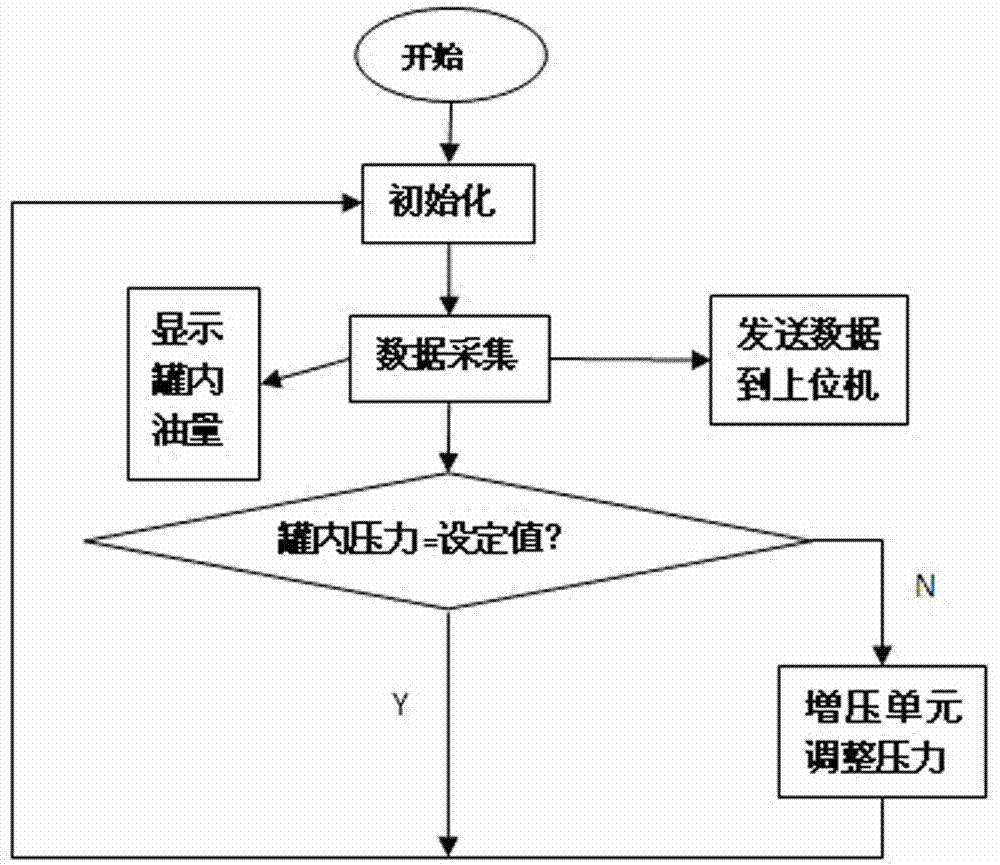

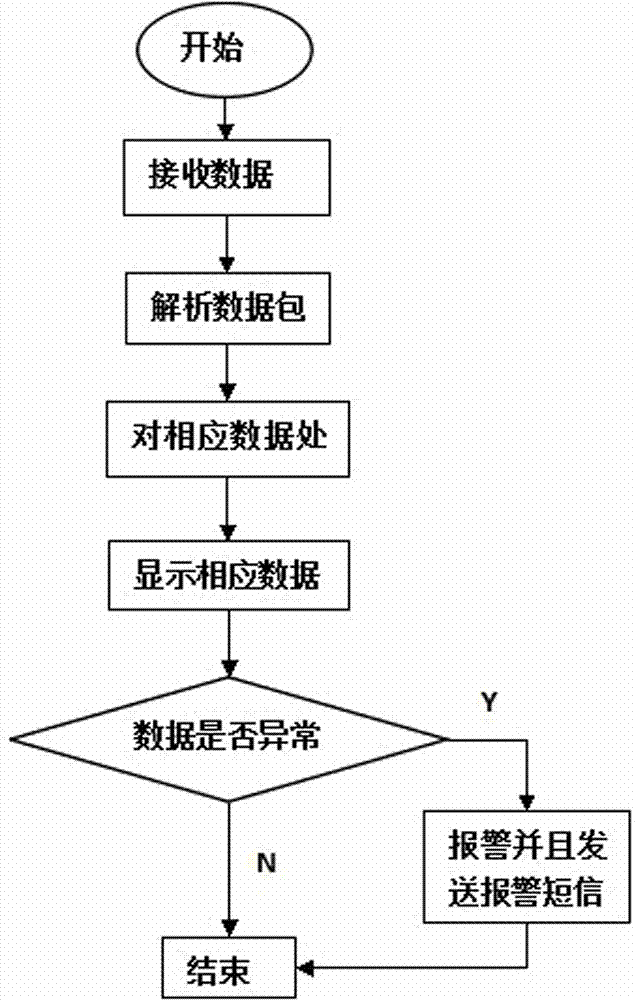

[0016] Examples of the present invention Figures 1 to 8 As shown, the digital intelligent drilling fuel tank applies computer technology, automatic control technology, wireless communication technology, and automatic detection technology, and is composed of an oil tank system and a host computer; the oil tank system is provided with a square tank body 1 and connected to The control cabin 2 on the tank body, the square tank body is convenient for accurate calculation, the electrical part is composed of flow acquisition unit, liquid level acquisition unit, temperature acquisition unit, inclination angle acquisition unit, display unit, fuel outlet pressure acquisition unit, Composed of GPS data acquisition unit, tank pressure control unit, efficiency detection unit, data transmission unit, and power supply unit. The flow acquisition unit is provided with a shut-off valve 15, an ultrasonic flowmeter 3, and a check valve 14 at the oil outlet 12. The ultrasonic flowmeter is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com