Powdery material level detection and control circuit

A powder material, control circuit technology, applied in liquid level control, non-electric variable control, control/regulation system and other directions, can solve the problems of low control accuracy, unreasonable material level measurement method, etc., to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

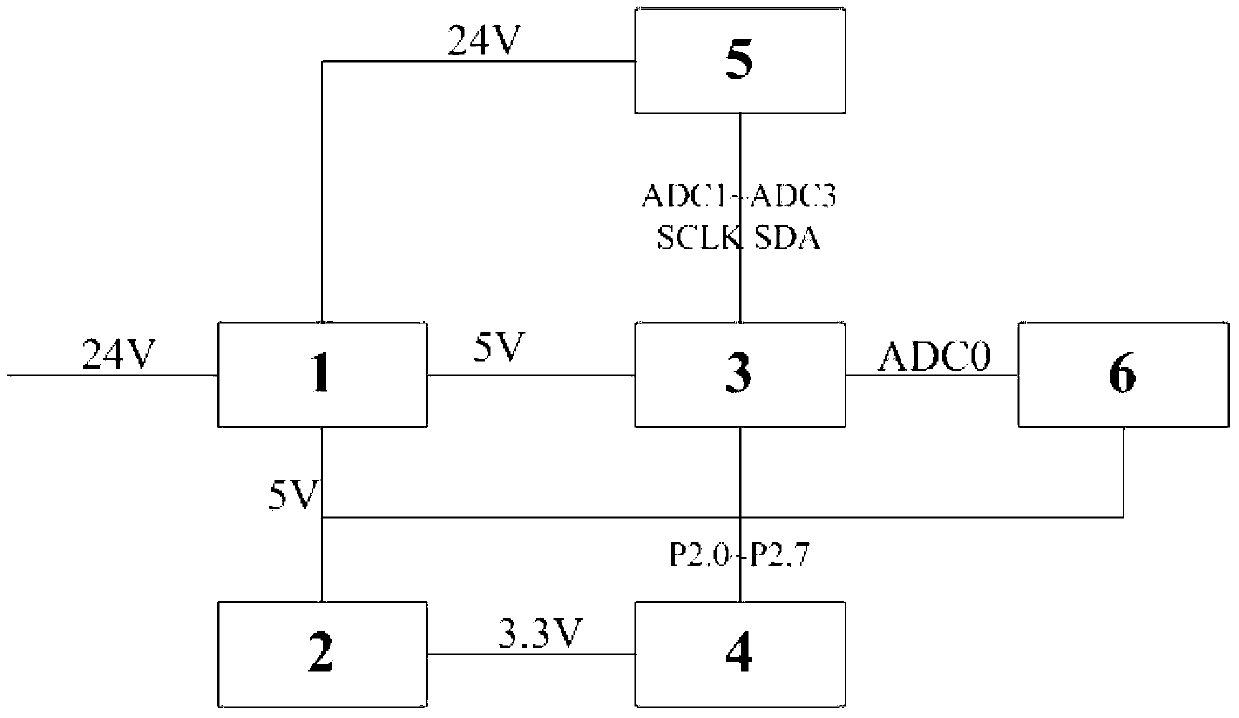

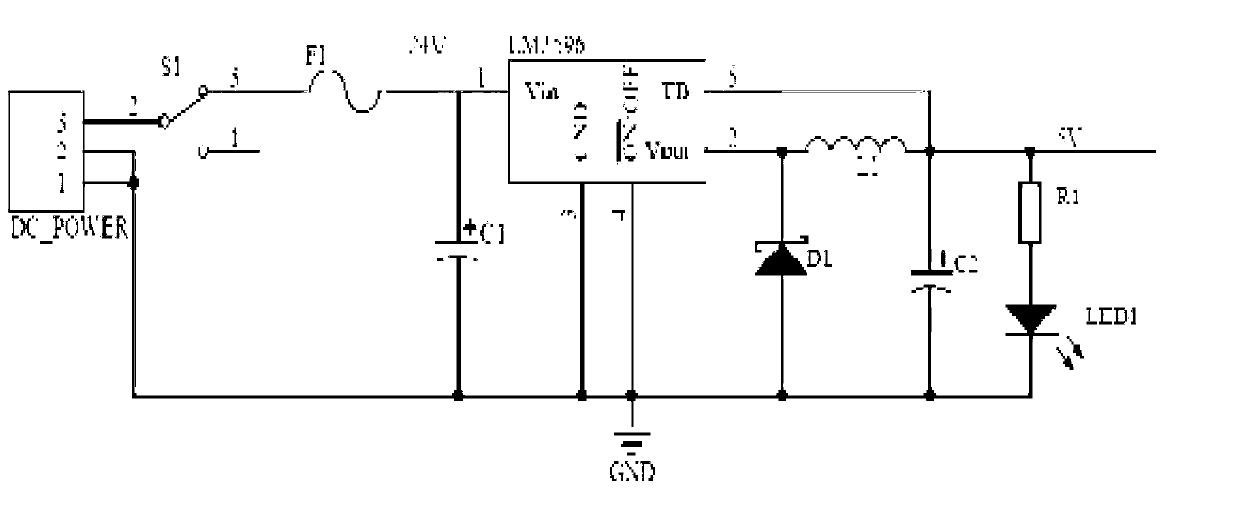

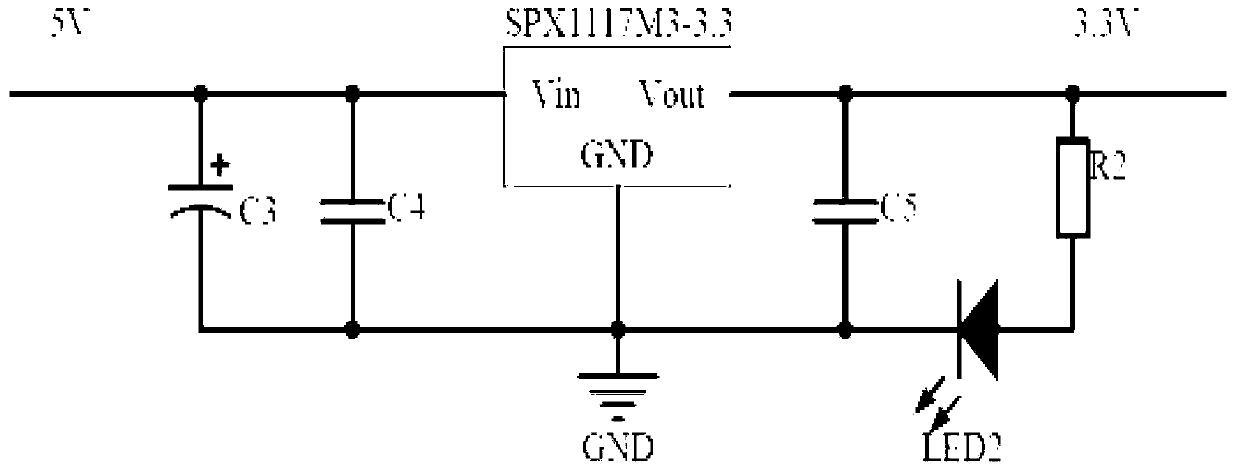

[0029] Specific embodiments of the present invention are shown in the accompanying drawings, figure 1 Shown is a schematic block diagram of the material level detection and control circuit, which is mainly composed of a first power module 1, a second power module 2, a control module 3, a display module 4, a signal detection module 5, and a flow control module.

[0030] The working process of the powder material level detection and control device is as follows: the power supply module provides a stable working voltage for the external detection circuit, and the controller obtains the result after processing the level signal or 4-20MA current signal returned from the outside . If the air pressure inside the container is too high and exceeds the warning value, the controller will send a PWM signal to the corresponding pin, thereby controlling the buzzer to sound an alarm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com