An automatic teller machine channel load self-checking device and method

A technology of automatic teller machines and self-checking devices, which is applied in the direction of complete banking systems, instruments, coin-free or similar appliances, etc., can solve the problems of reducing machine usage, increasing maintenance costs, and having no alarm mechanism, etc., to reduce unnecessary Necessary burden, improvement of maintenance efficiency, effect of avoiding belt breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

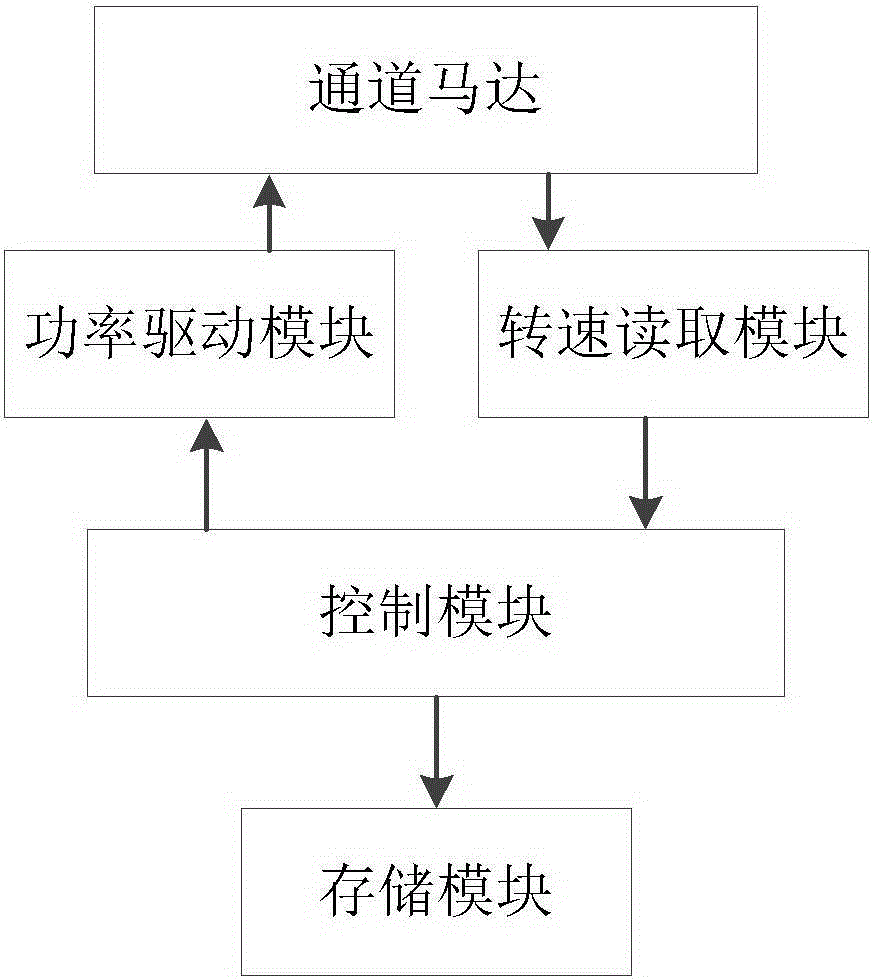

[0028] Such as figure 1 , An automatic teller machine channel load self-checking device, including: a control module, which communicates with the speed reading module to read the motor speed in real time; communicates with the motor power drive module to control the motor speed; connects with the storage module to store each reading The power value taken; compare the motor speed read in real time with the preset power threshold, and judge the load status of the ATM according to the comparison result. The preset power threshold includes the minimum power value and the safe power Threshold T1, alarm power threshold T2 and limit value T3, according to the rated power of the motor is P1 and the maximum allowable power is P2, the control module detects that the current motor speed exceeds the safe power threshold T1 and does not exceed the alarm power threshold T2. The control module only sends out an alarm; the control module detects that the current motor speed exceeds the alarm po...

Embodiment 2

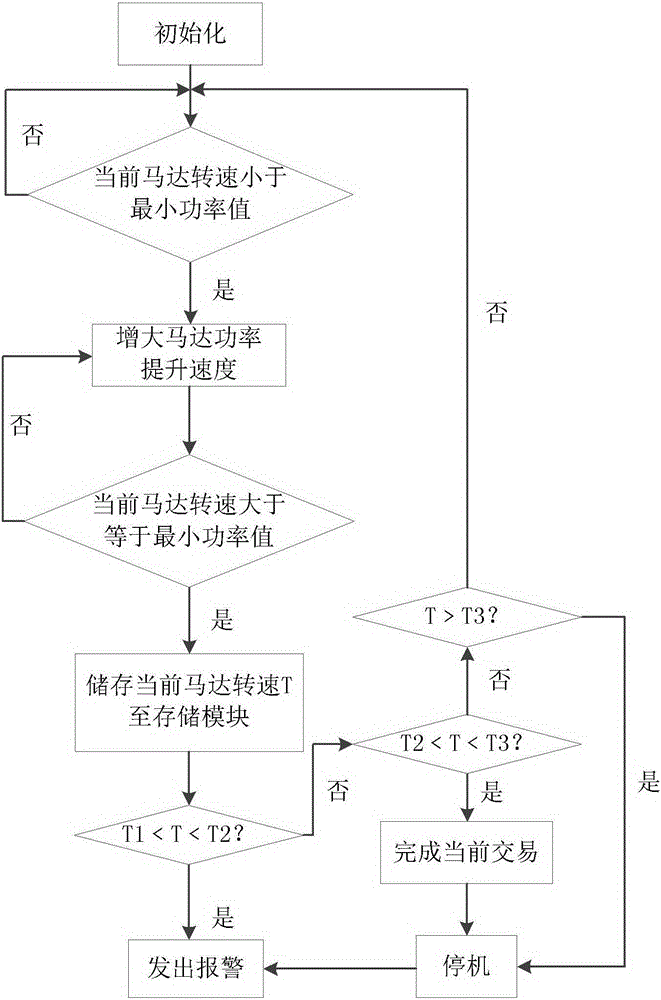

[0030] Such as figure 2 , A self-checking method for automatic teller machine channel load, including the following steps:

[0031] Step 1. After initialization, the speed reading module reads the current motor speed in real time, and sends the read current motor speed value to the control module, and the control module converts the motor speed into the corresponding power value T;

[0032] Step 2. The control module compares the current motor speed T with the preset power threshold T'. The power threshold T'can be divided into three levels of power thresholds: safe power threshold T1, alarm power threshold T2, and limit value T3; According to the rated power of the motor is P1 and the maximum allowable power is P2, the safe power threshold T1, alarm power threshold T2 and limit value T3 are respectively: T1=P1; T2=P1+10%*(P2- P1); T3=P2; For example, if the rated power of a certain type of motor is 100W and the maximum allowable power is 196W, then T1=100W, T2=109.6W, T3=196W;

...

Embodiment 3

[0036] The control module compares the current motor speed T with the preset power threshold T'. The power threshold T'can be divided into three levels of power thresholds: safe power threshold T1, alarm power threshold T2, and limit value T3; The rated power of the motor is P1 and the maximum allowable power is P2. The safe power threshold T1, alarm power threshold T2, and limit value T3 are respectively: T1=P1; T2=P1+30%*(P2-P1); T3=P2; For example, if the rated power of a certain type of motor is 100W and the maximum allowable power is 196W, then T1=100W, T2=128.8W, T3=196W;

[0037] If T≤100W, the channel is in a normal load state, if 100W<T<128.8W, the ATM needs maintenance personnel to check at this time, and the control module issues an alarm. Since the alarm power threshold T2 is not exceeded, the automatic teller can continue to work; If 128.8W≤T﹤196W, the ATM does not exceed the limit value T3 at this time, the control module will automatically stop after the current tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com