Lean burn active ignition engine with aftertreatment system and method

An engine and engine system technology, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve problems such as NOx reduction and reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Various aspects are described below with reference to exemplary embodiments for easy understanding of the present disclosure. However, the present disclosure should not be viewed as limited to these embodiments. Rather, these embodiments are provided so that this disclosure will be thorough and complete. Descriptions of well-known functions and constructions may not be provided for clarity and conciseness.

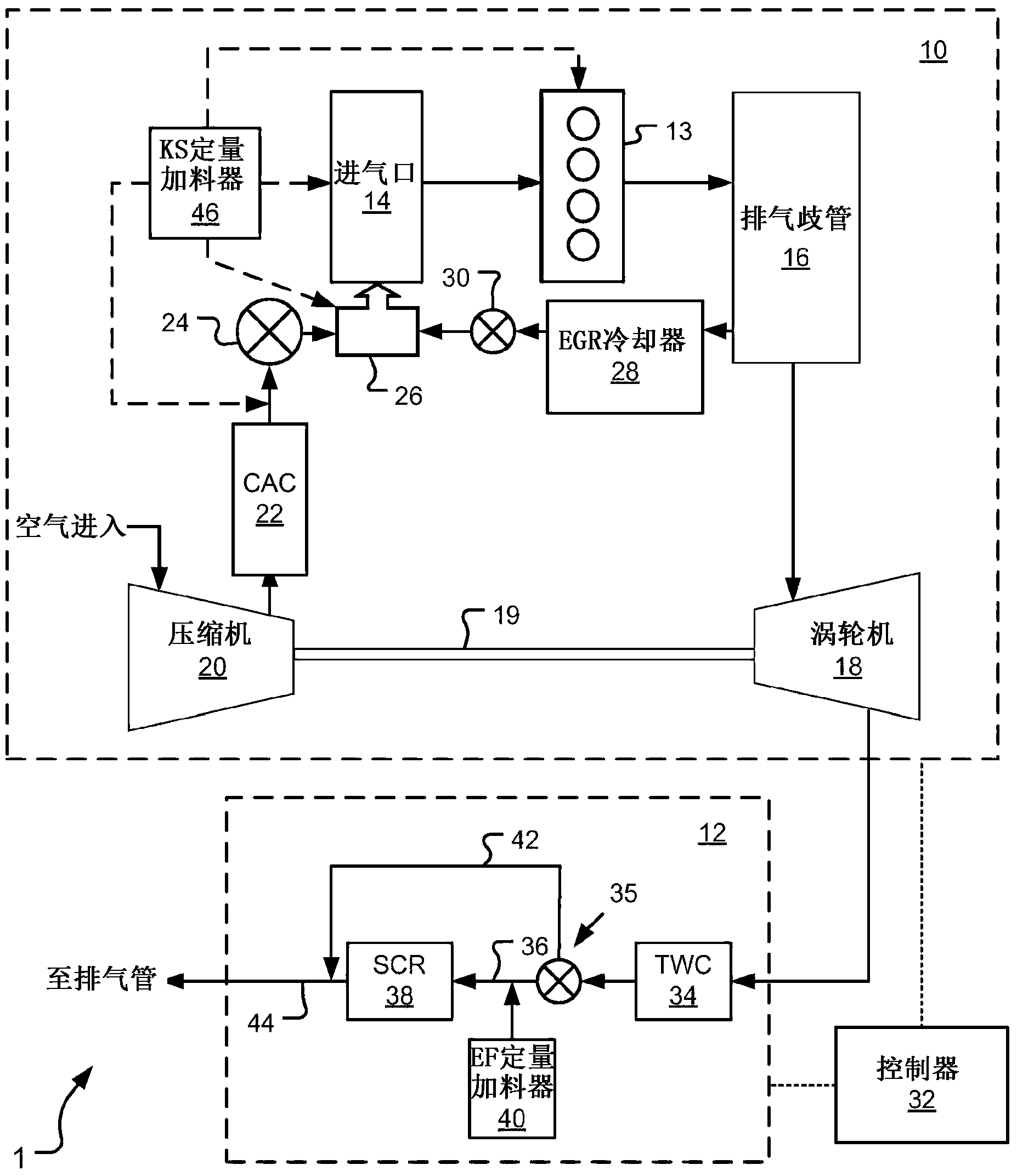

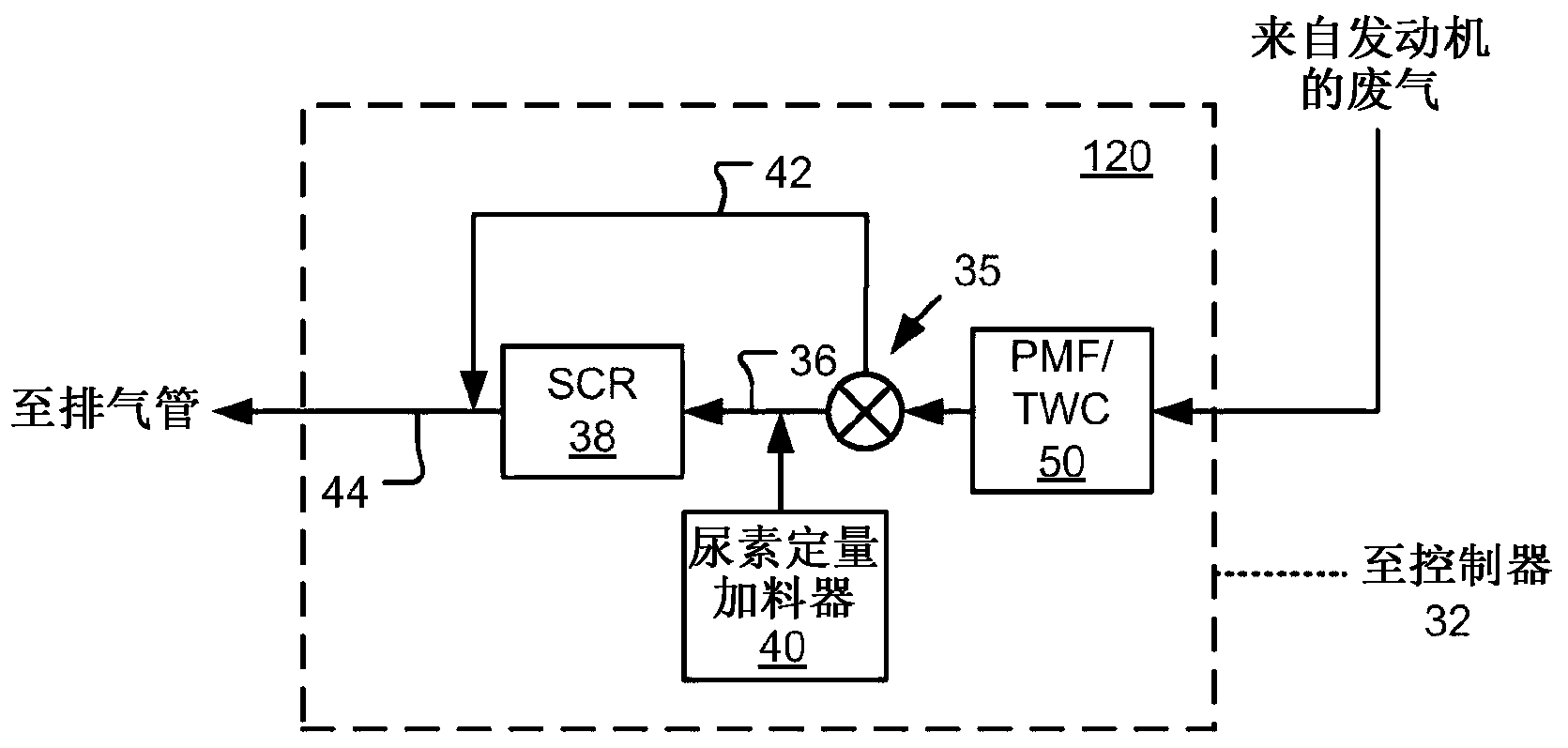

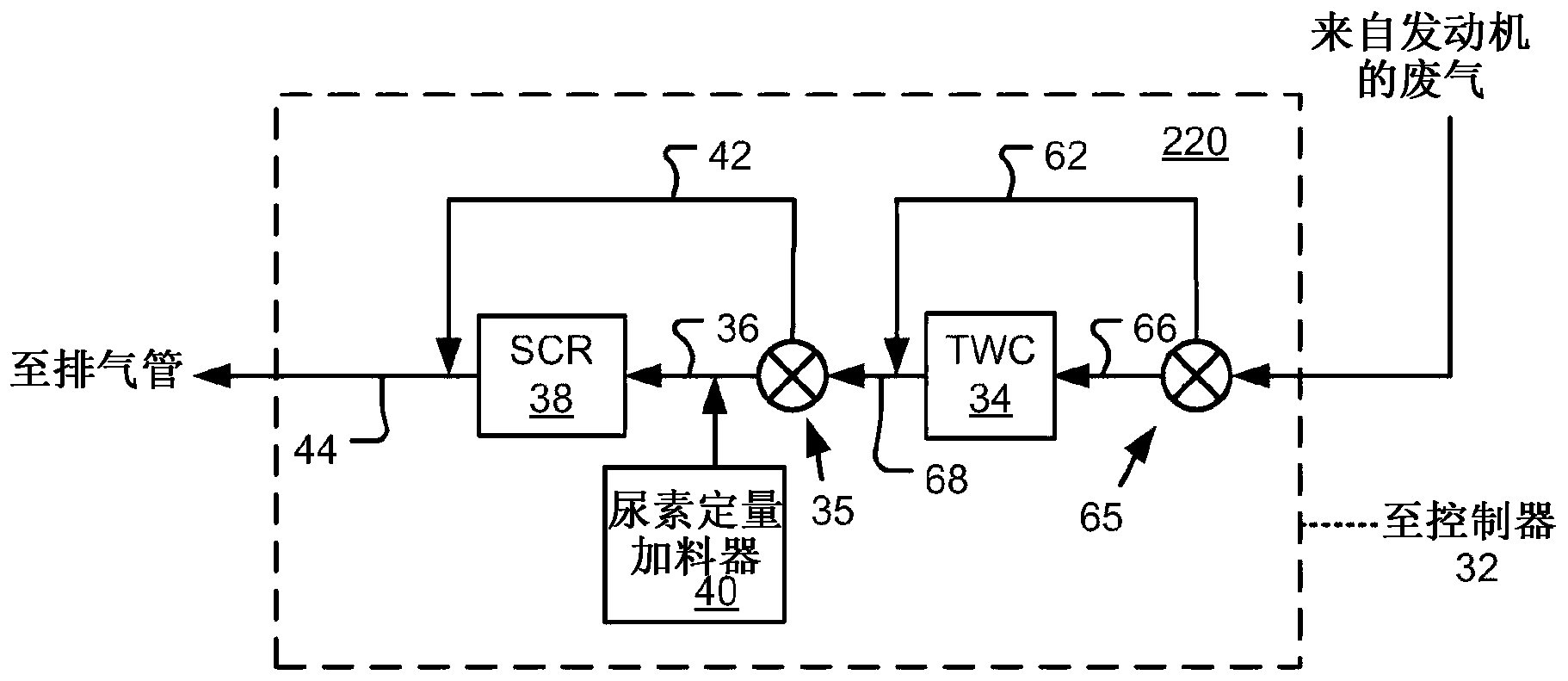

[0013] The present inventors have realized that it is possible to achieve this by utilizing an actively-ignition internal combustion engine (e.g., an engine utilizing gasoline, natural gas, ethylene-based fuels) running lean-burn conditions, with or without turbocharging, supercharging, or other means of boosting. Achieve significant fuel economy gains. As used herein, the term "active ignition engine" describes an engine in which an action is required to initiate combustion of the charge air / fuel mixture in the cylinders of the engine, such as a spark ignition (S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com