Machine-manufactured natural sand grading adjustment system and manufacturing method of natural sand

A technology of adjusting system and grading adjusting machine, applied in the field of machine-made sand manufacturing, can solve the problems of raw material waste, immature use, low production capacity, etc., and achieve the effect of avoiding raw material waste, avoiding pollution and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

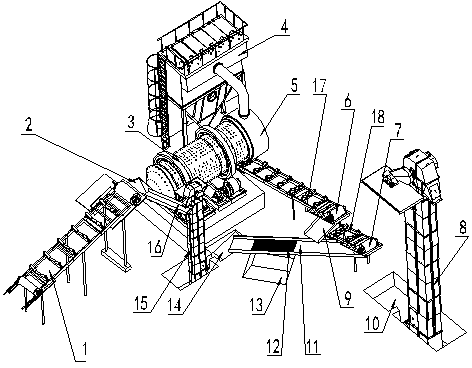

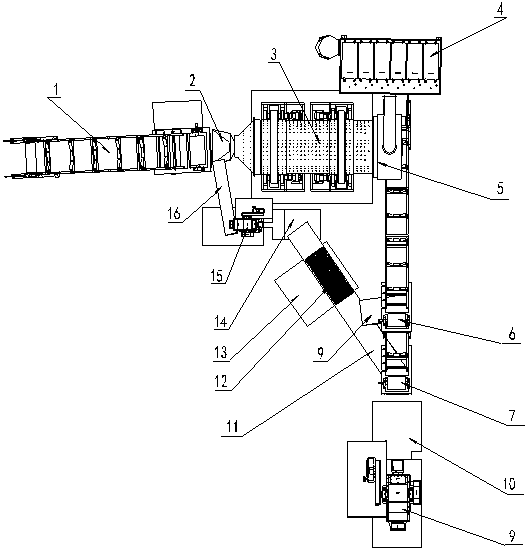

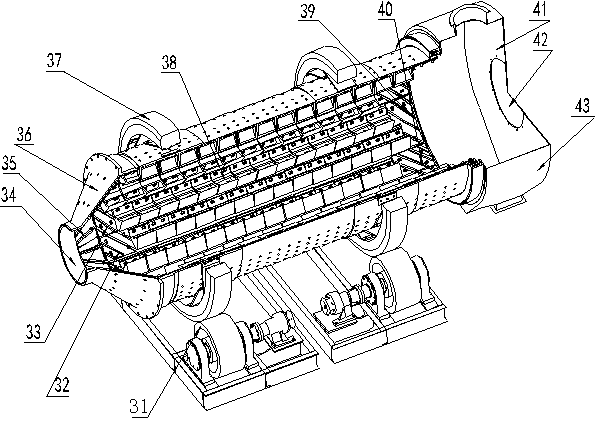

[0016] Embodiment 1: with reference to attached Figure 1-7 . A mechanical natural sand gradation adjustment system. The discharge end of the feed conveyor belt 1 is directly facing the feed port of the steel sand mixing hopper 2. The steel sand mixing hopper 2 is discharged through the steel ball feeding chute 16 and the tower type steel ball bucket elevator 15. The material inlet is opposite, the bottom end of the tower type steel ball bucket elevator 15 is located in the crude steel particle trough 14, the outlet of the steel sand mixing hopper 2 is connected with the inlet of the machine-made sand grading adjustment machine 3, and the machine-made sand grading adjustment machine 3. The dust collection cover 5 communicates with the dust collector 4 through the conveying pipe. The discharge port of the machine-made sand grading adjustment machine 3 is opposite to the feed end of the discharge conveyor belt 17. A first-stage electromagnetic filter is installed above the disch...

Embodiment 2

[0031] Example 2: On the basis of Example 1, a method for making natural sand in a machine-made natural sand gradation adjustment system, the feed conveyor belt 1 sends the machine-made sand that needs to be adjusted in gradation into the steel sand mixing hopper 2. At the same time, the tower The type steel ball bucket elevator 15 adds steel balls to the steel sand mixing hopper 2 through the feed chute 16. After the above two materials are mixed, they enter the machine-made sand grading adjustment machine 3, and through the continuous rotation of the machine-made sand grading adjustment machine 3, With the step-by-step counter-attack hopper 38 continuously improving and stepping, the machine-made sand is continuously crushed and ground, and then the machine-made natural sand is continuously sent out from the machine-made sand grading adjustment machine 3 discharge port 44. The dust removal hole 45 of the dust collector suction hood 43 on the upper part of the feed port contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com