3D stack printing method and 3D stack printer

A printer and 3D technology, applied in the field of 3D printing, can solve the problems of small applicable product range, slow printing, and few types of consumables, and achieve the effect of novel design ideas, overcoming slow printing, and unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

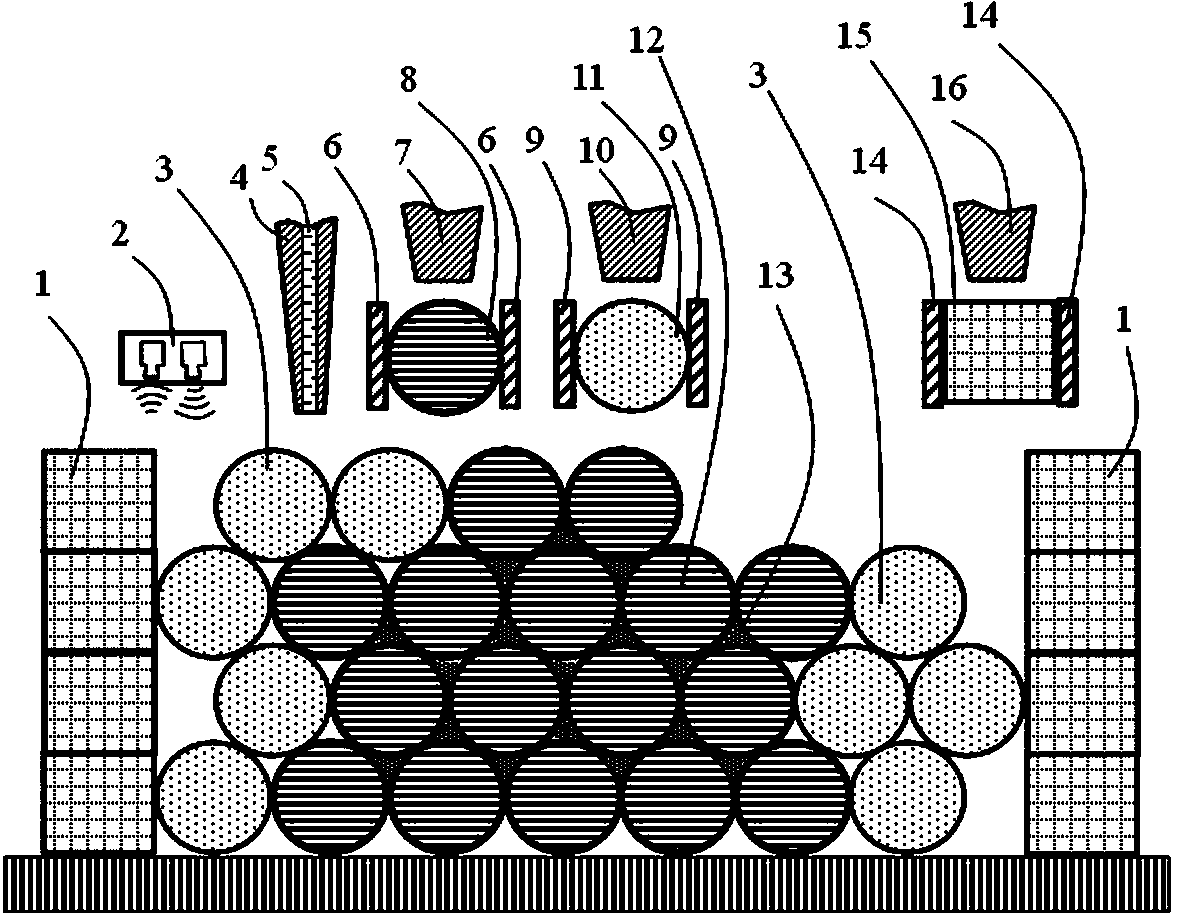

[0024] The 3D stack printing method includes printing consumables and printing auxiliary materials, wherein the consumables are preformed prefabricated consumables. Fast stack-up printing of models or products with relatively low precision requirements by using pre-formed preform consumables and their accessories.

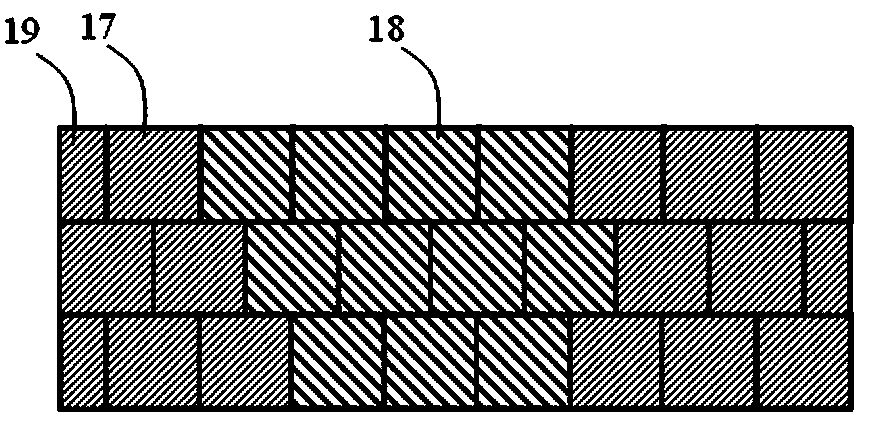

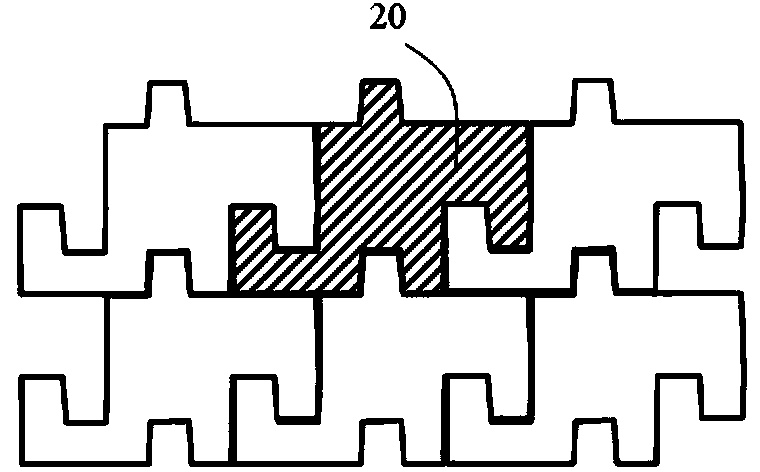

[0025] The preformed prefabricated consumables are 3D stacked printing units, whose unit shape is square, rectangular, hexagonal, cylindrical, spherical, or a shape that can be interlocked and interlocked with itself (such as image 3 20 self-connected interlocking mosaic units), these stacked printing units can be prefabricated, or processed on-site by pressing, mold forming, stamping, cutting and cutting.

[0026] The preformed prefabricated consumables, that is, the 3D stacked printing unit can be solid body, hollow body, microporous (foaming) body, elastic body; the materials used can be various metals, plastics, rubber, ceramics, glass, food materials Some kin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com