Remote-control comprehensive locomotive oil and water make-up system

A technology of remote control and replenishment system, applied in the field of remote control locomotive oil and water comprehensive replenishment system, can solve the problem of no remote control, etc., and achieve the effect of rapid replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

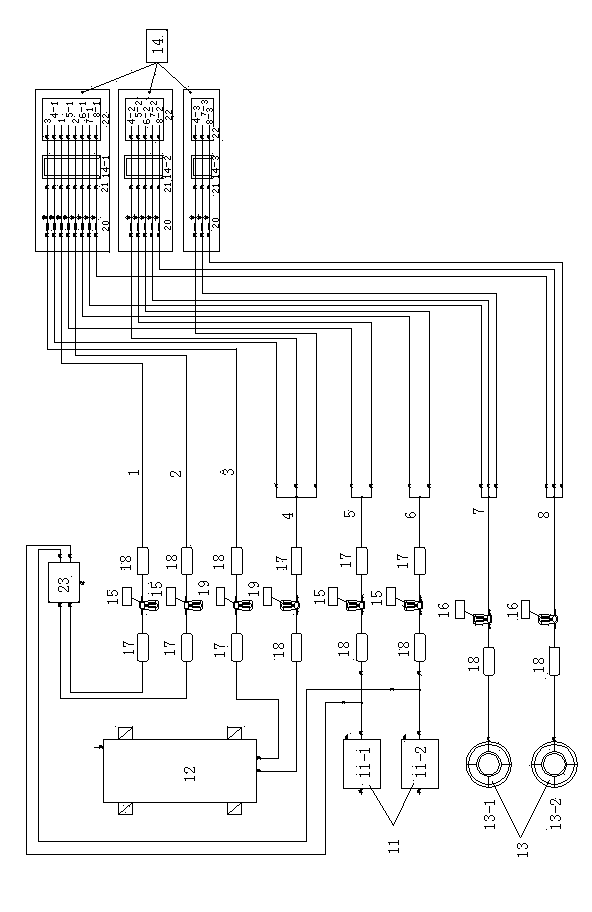

[0018] Such as figure 1 It is a structural schematic diagram of the present invention, a remote control locomotive integrated oil-water supply system, including an engine oil supply storehouse 11, a fuel supply storehouse 12, a cooling water supply storeroom 13 and a remote control terminal 14, and the remote control terminal 14 is provided with three microcomputer points The consoles are sub-console 14-1 for refueling and watering line, sub-console 14-2 for water resistance test bench, and sub-console 14-3 for delivery station. The pipelines are equipped with pressure monitoring 20, electric control valve 21, and liquid filling seat 22. The engine oil supply depot 11 includes a fourth-generation oil depot 11-1 and a fifth-generation oil depot 11-2. The engine oil supply depot 11 is provided with an independent fourth-generation oil pumping circuit 1, a fifth-generation oil pumping circuit 2, and a fourth-generation oil refueling circuit 5. The fifth-generation engine oil ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com