Inventory area integrating stocking and sorting, inventory management system and inventory management method

An inventory management and integrated technology, applied in the field of warehousing, can solve problems such as low work efficiency, low degree of automation, and heavy workload of operators, and achieve the effects of reducing workload, improving work efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

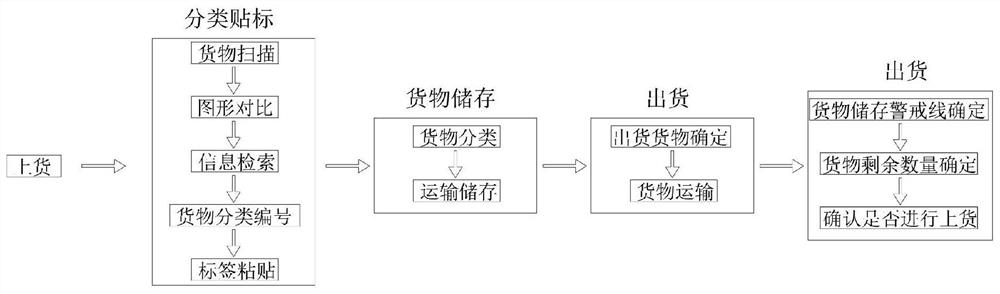

[0050] see figure 1 As shown, the present invention is an inventory area and an inventory management method integrating stock preparation and picking, and the method includes the following steps:

[0051] S1. Loading, used to move the goods to the goods pre-arrival area;

[0052] S2. Classification and labeling, which is used to classify the goods and paste labels. The labels are provided with two-dimensional codes, and the detailed information of the goods can be obtained by scanning the two-dimensional codes;

[0053] Here, the detailed information includes the type, shape, serial number and loading time of the goods;

[0054] The classification and labeling at least consists of the following steps:

[0055] S201. Cargo scanning, used to scan the shape of the goods and form a three-dimensional graphic;

[0056] S202. Graphic comparison, which is used to compare the 3D graphics with the cargo graphics stored in the server, and retrieve the graphics with the highest similar...

Embodiment 2

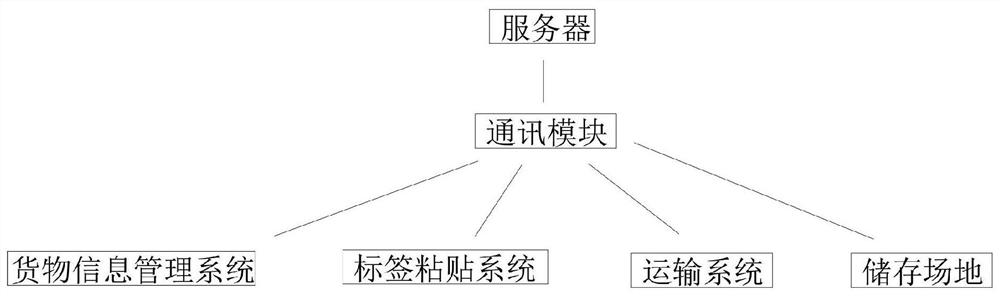

[0075] On the basis of Embodiment 1, a kind of storage area and inventory management system integrating stock preparation and picking is disclosed, please refer to figure 2 As shown, the system includes:

[0076] The server is used to store the shape and detailed information of various types of goods, monitor and record the quantity and time of goods loaded and shipped in real time, and set a warning line for goods storage;

[0077] A transport system for transporting goods, the transport system may be one or more of a forklift, a mechanical arm, a crane, and a transport belt;

[0078] Here, the forklift, the mechanical arm, the crane and the conveyor belt are all equipped with scanning guns for scanning the two-dimensional code;

[0079] A storage site, which is divided into a cargo pre-entry area, a cargo storage area and a shipping area;

[0080] The cargo information management system is used to manage the information of the cargo, and the cargo information management s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com