Surface drying device used during copper wire tinning

A technology for surface drying and tinning of copper wires, applied in heating devices, progressive dryers, drying solid materials, etc., can solve the problems affecting the working efficiency of the tinning process and the tin liquid is easy to remain on the surface of copper wires, etc., to achieve reduction Effects of waiting time, preventing bending, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

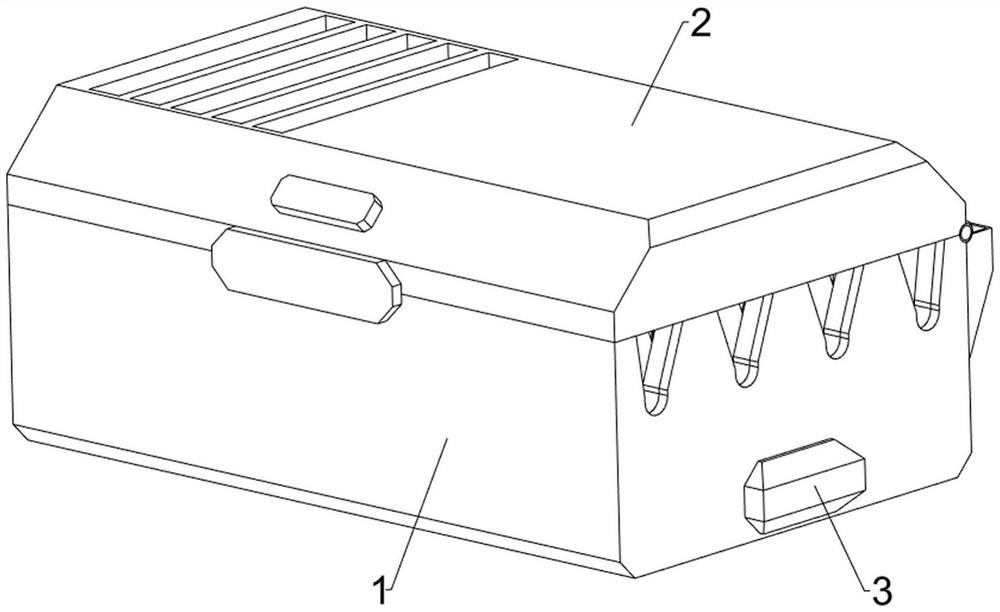

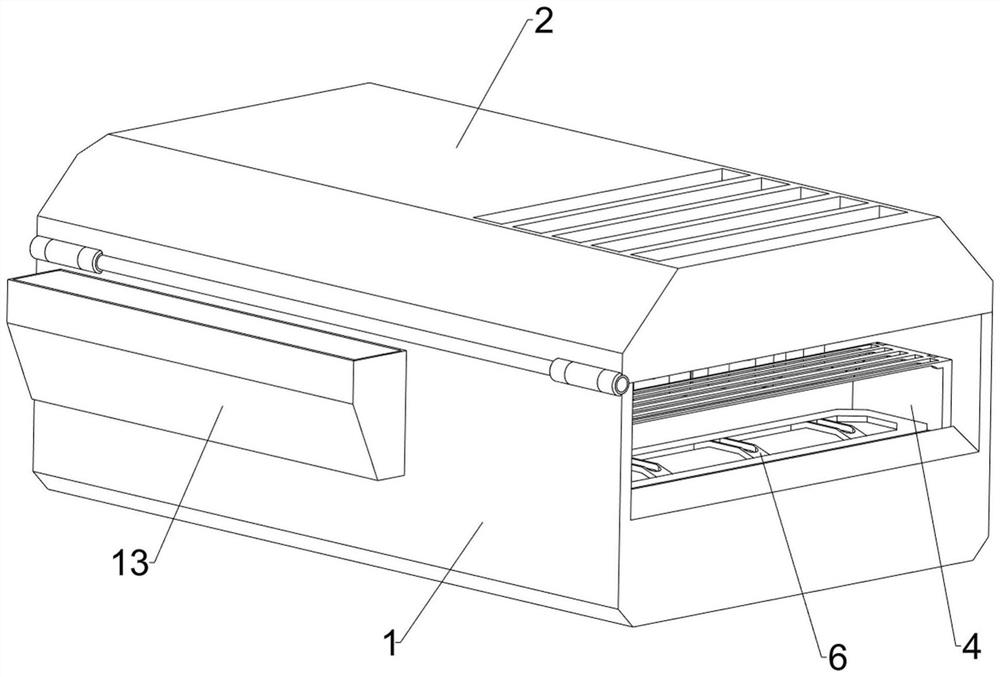

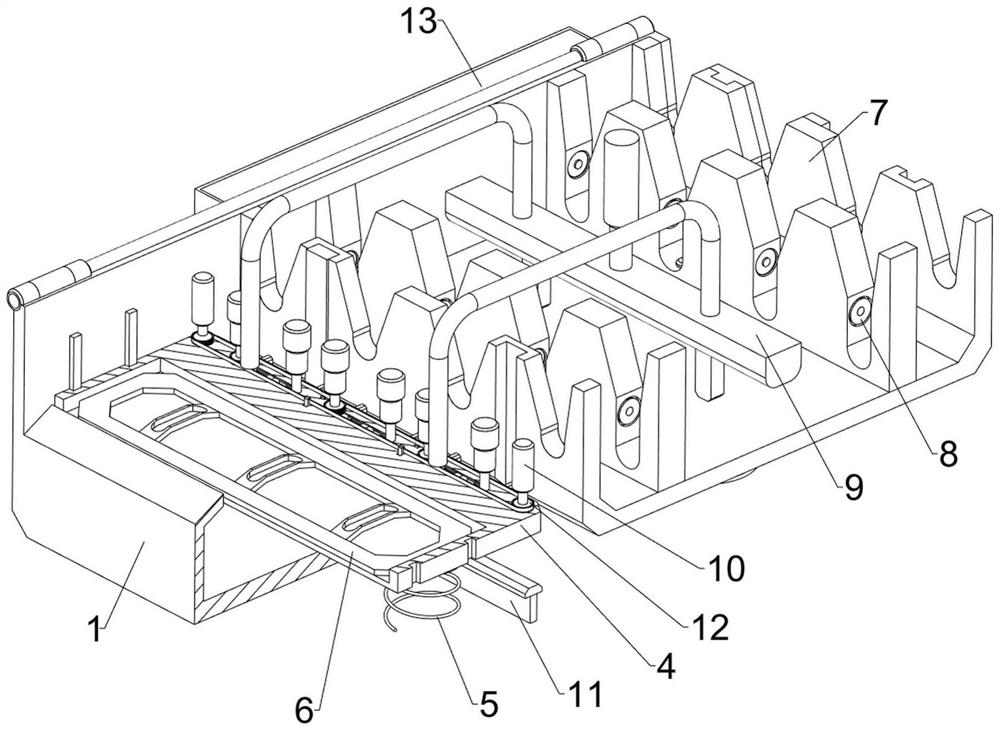

[0038] A surface drying device for copper wire tinning, such as Figure 1-Figure 10 As shown, it includes a working box 1, a cover 2, a connecting frame 4, a first spring 5, a heating plate 6, a tinning component 7, an auxiliary fixing component 8, a pressing component 9 and an adjusting component 10, and the rear side of the top of the working box 1 The rotating type is provided with a cover 2, and the sliding type is provided with a connecting frame 4 on the upper left side inside the working box 1. There are two first springs 5 between the bottom of the connecting frame 4 and the working box 1. There is a heating device on the left side of the connecting frame 4. Plate 6, after heating plate 6 starts working, can heat the copper wire after tinning, work box 1 inner upper side is provided with tinning assembly 7, copper wire is placed on the tinning assembly 7, tinning assembly 7 can Tinning the copper wire, the tinning assembly 7 is provided with an auxiliary fixing assem...

Embodiment 2

[0045] On the basis of Example 1, such as figure 2 , image 3 , Figure 11 , Figure 12 , Figure 13 , Figure 14 with Figure 15 As shown, a wire take-up assembly 11 is also included, and the wire take-up assembly 11 includes a distance sensor 1101, a drive motor 1102, a transmission wheel 1103 and a belt 1104, and a distance sensor 1101 is arranged at the left middle part of the inner bottom of the working box 1, and the inside of the connecting frame 4 The lower part of the rear side is provided with a driving motor 1102. After the driving motor 1102 starts to work, it can drive the auxiliary roller 101 to rotate. The output shaft of the driving motor 1102 is provided with a drive wheel on the lower side of the second connecting rod 102 which is not adjacent to four of them. 1103 , a belt 1104 is wound between the transmission wheels 1103 .

[0046] Also includes a limiting assembly 12, the limiting assembly 12 includes a T-shaped limiting rod 1201, a clamping rod 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com