Rotary type particle filling machine

A filling machine, rotary technology, applied in the field of rotary granule filling machine, can solve the problems of affecting filling quality, complex manufacturing process, short service life, etc., and achieve the effect of simple structure, expanded application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

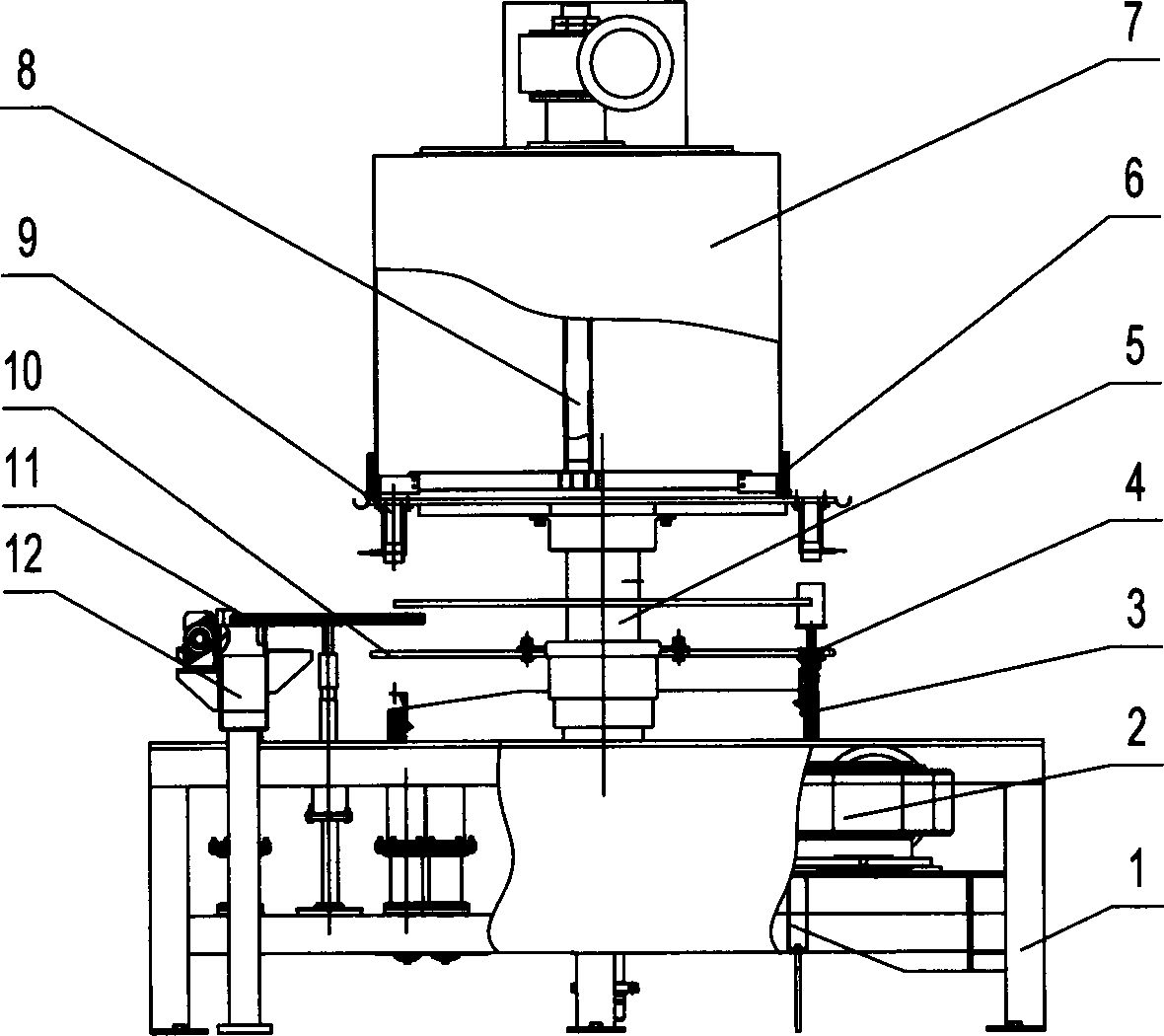

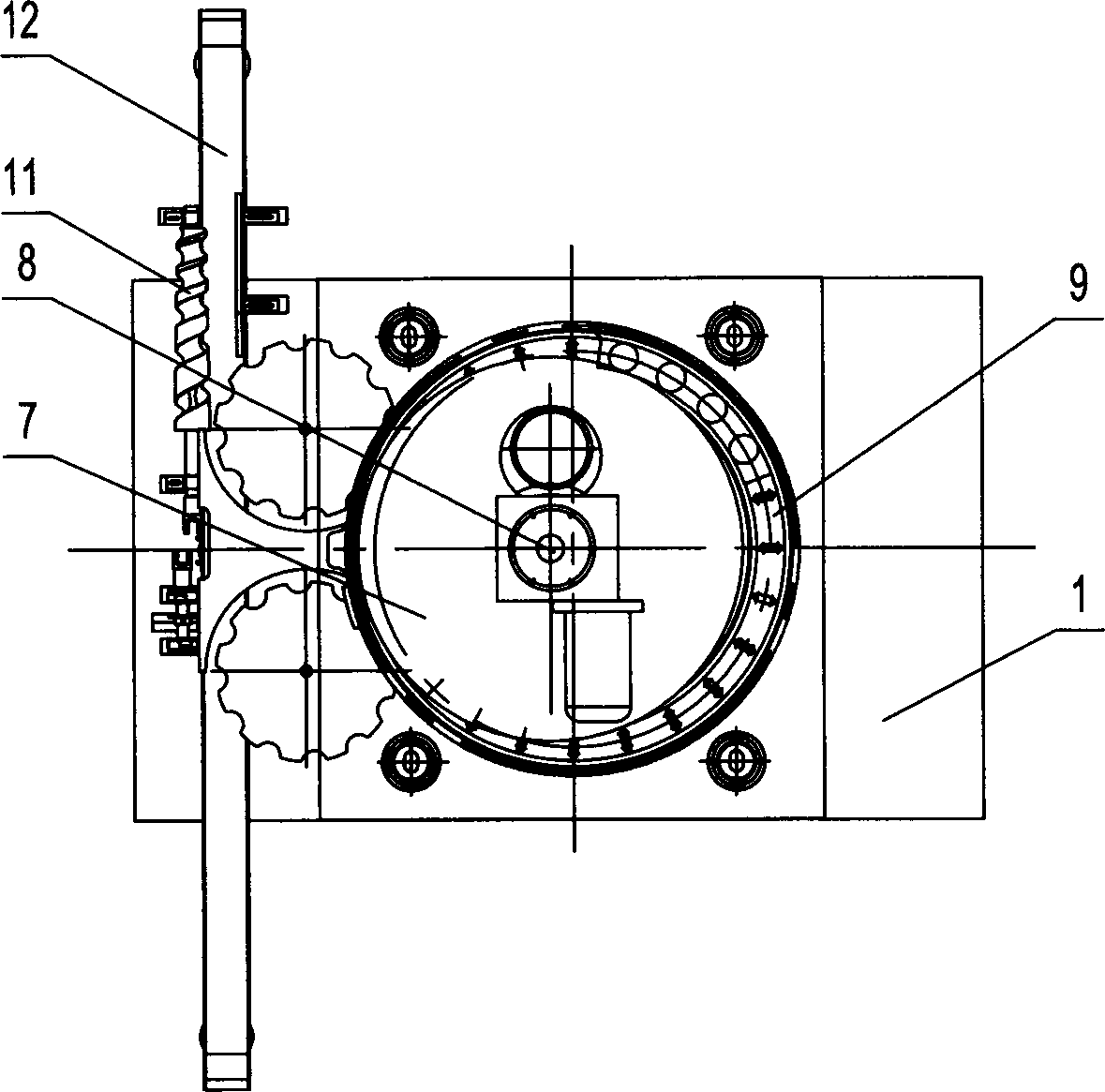

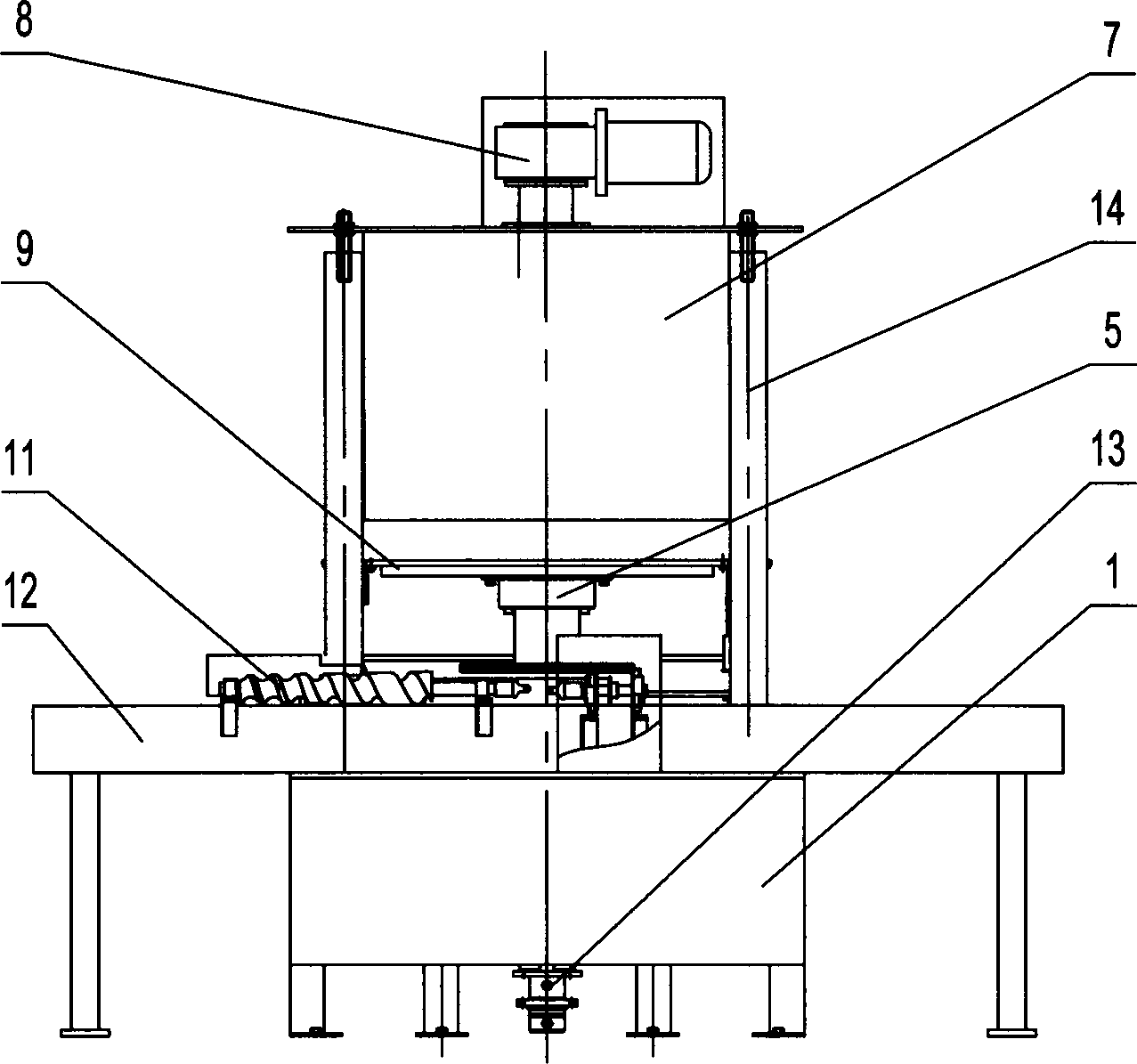

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] Figure 1 to Figure 10 Among them, including frame 1, main transmission device 2, track 3, bottle supporting device 4, main shaft 5, sealing device 6, material box 7, stirring device 8, filling metering device 9, filling platform 10, bottle separating device 11 , conveying device 12, lifting device 13, column 14, stirring bracket 15, gear motor 16, agitator 17, stirring shaft 18, scraper mechanism 19, stirring bushing 20, straight scraper 21, arc scraper 22, soft Scraper 23, outer pressure plate 24, seal ring 25, screw 26, top side pressure plate 27, pressure plate 28, inner pressure plate 29, bolt 30, nut 31, rotary disc 32, main flange 33, feeding hole 34, hoop 35 , Oil tank 36, upper measuring cup 37, lower measuring cup 38, gate plate 39, gate box 40, feeding pipe 41, etc.

[0028] Such as Figure 1 ~ Figure 3 As shown, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com