Epoxy resin-modified rubber asphalt

A technology of epoxy resin and modified rubber, used in building components, building insulation materials, buildings, etc., to achieve good rutting resistance, extended service life, and less stress damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

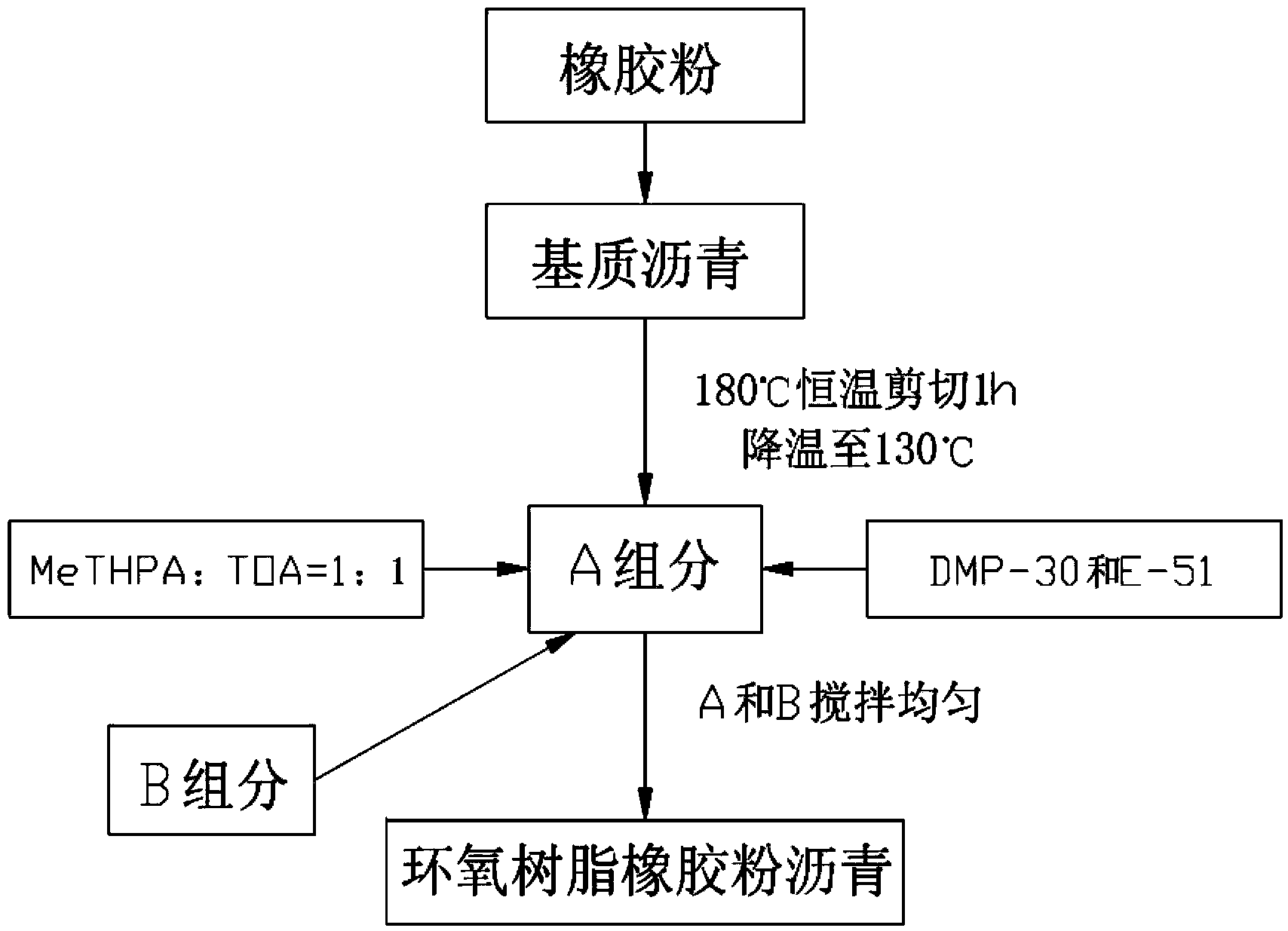

[0012] Add rubber powder with 18% of the weight of asphalt to the base asphalt at 170~180°C, and after shearing and stirring for 1 hour, slowly cool down to 130°C, add compound compound with 40% of the weight of base asphalt to the rubber asphalt sheared at 6000 rpm Mix curing agent, 2,4,6-tris(dimethylaminomethyl)phenol (DMP-30) with 5% weight of base asphalt and epoxy resin E-51 with 5% weight of base asphalt to obtain component A; group B The component is E-51 epoxy resin; the components A and B are mixed according to the ratio of 2:1 by weight at 120°C for 20 minutes to obtain the epoxy resin modified rubber asphalt. The compound curing agent is prepared by reacting methyl hexahydrop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretching rate | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com