Stand-by pump automatically-starting control logic device with two pumps mutually serving as stand-by pumps

A standby pump and pump control technology, which is applied in the field of control logic, can solve the problems that the efficiency of the standby pump cannot be fully utilized, the working pump is easily fatigued and damaged, and the reliability is poor, so as to achieve the effects of easy operation, reliable startup, and reduced malfunction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

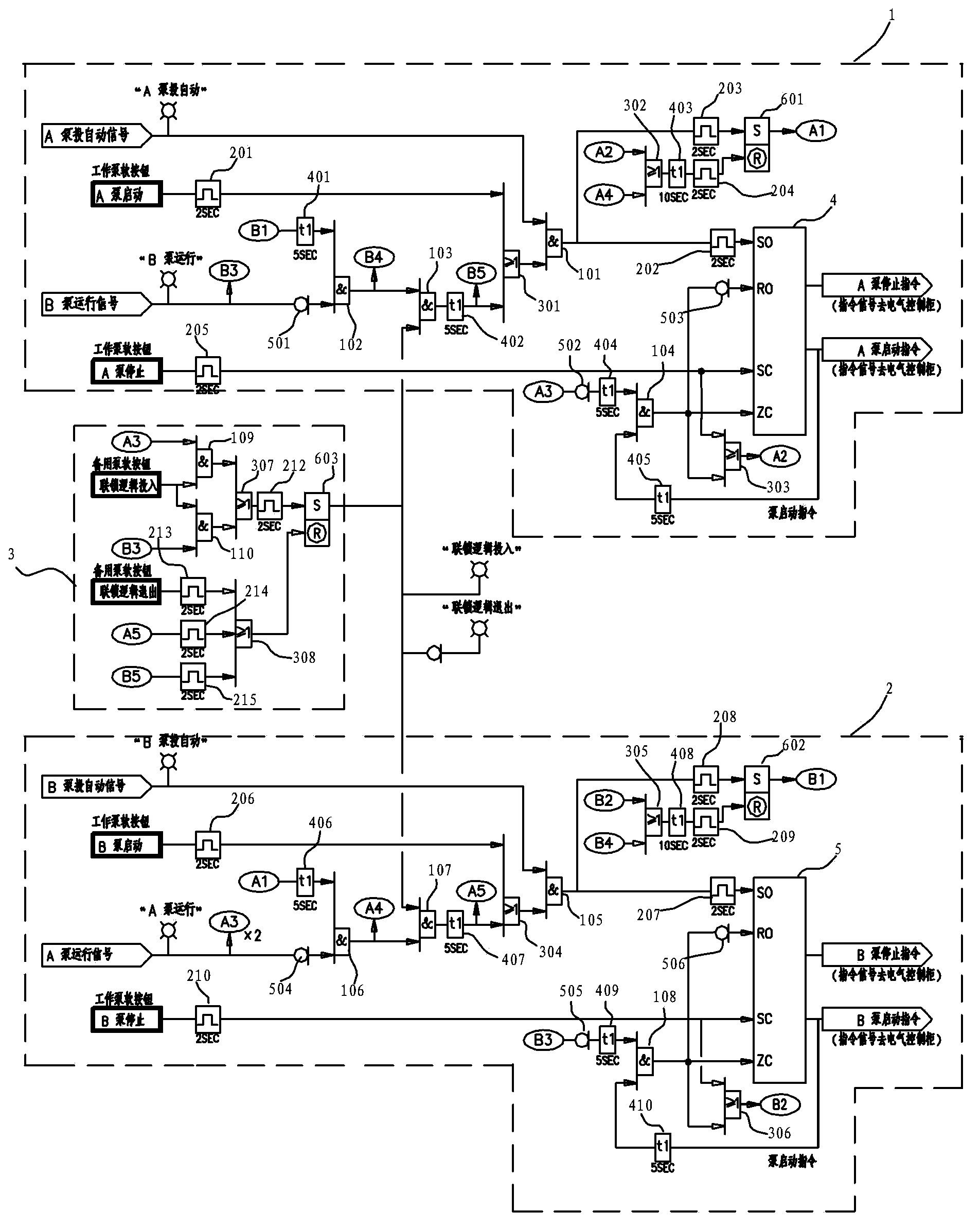

[0069] The two pumps provided in this embodiment are mutually standby and the control logic of automatically starting the standby pump is set in the control system and connected with the electrical control cabinet for controlling the A pump and the B pump, and the electrical control cabinet is connected to the output There are dry contact signals for automatic switching of pump A, dry contact signals for automatic switching of pump B, dry contact signals for pump A running, and dry contact signals for pump B running. The above control logic includes pump A control logic 1 and pump B control logic 2 , Interlock logic control module 3 three modules, A pump control logic 1, B pump control logic 2 electrical control loop wiring mode is completely consistent, specifically:

[0070] A pump control logic 1 consists of:

[0071] The A pump automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com