Reinforced synchronizer

A synchronizer and force-enhancing technology, applied in clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problem of reducing the working reliability of the self-enhancing synchronizer, increasing the production cost of the self-enhancing synchronizer, and affecting the force increase. It can achieve significant economic and social benefits, reduce the volume of the drive device, and reduce the output force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

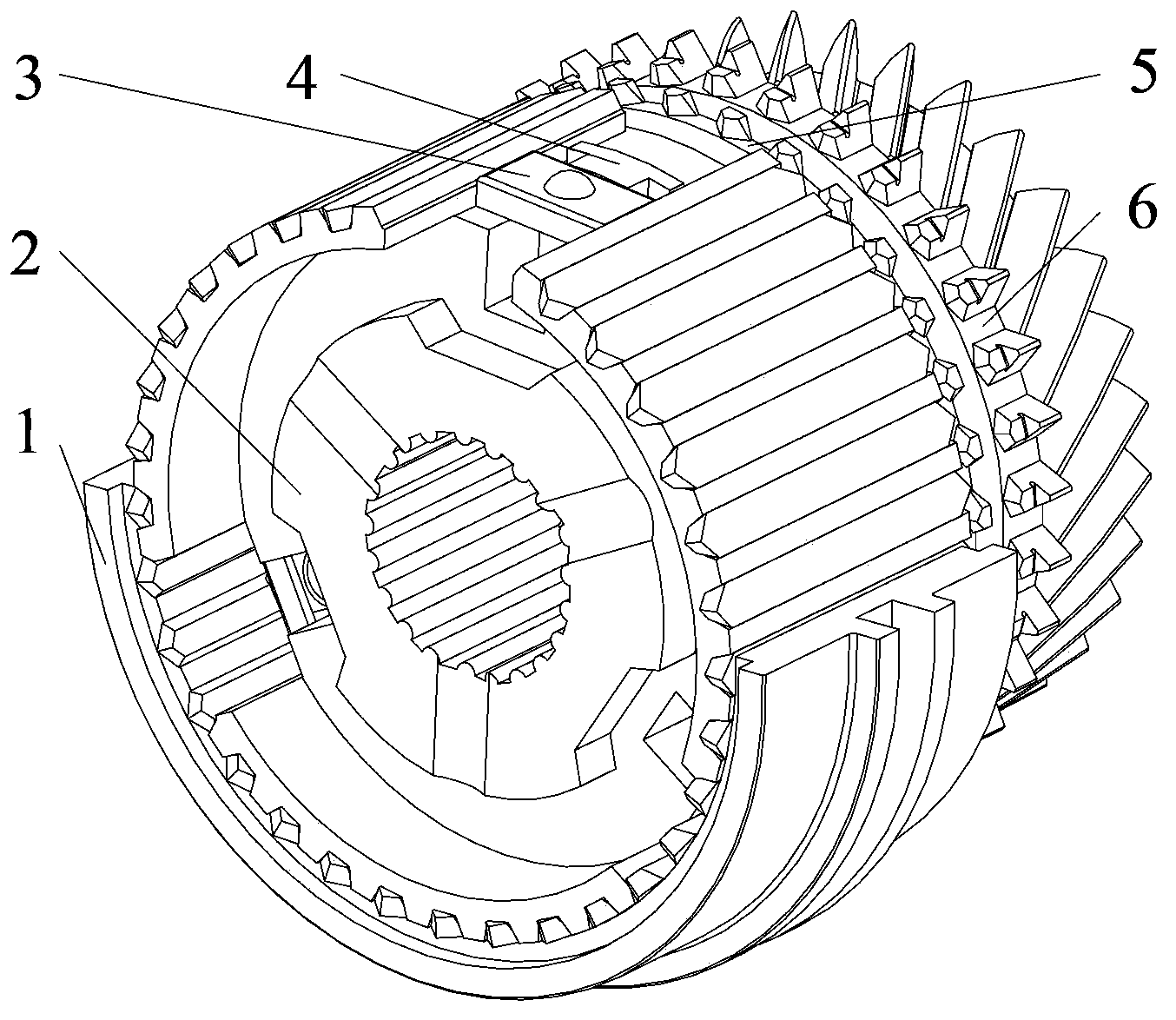

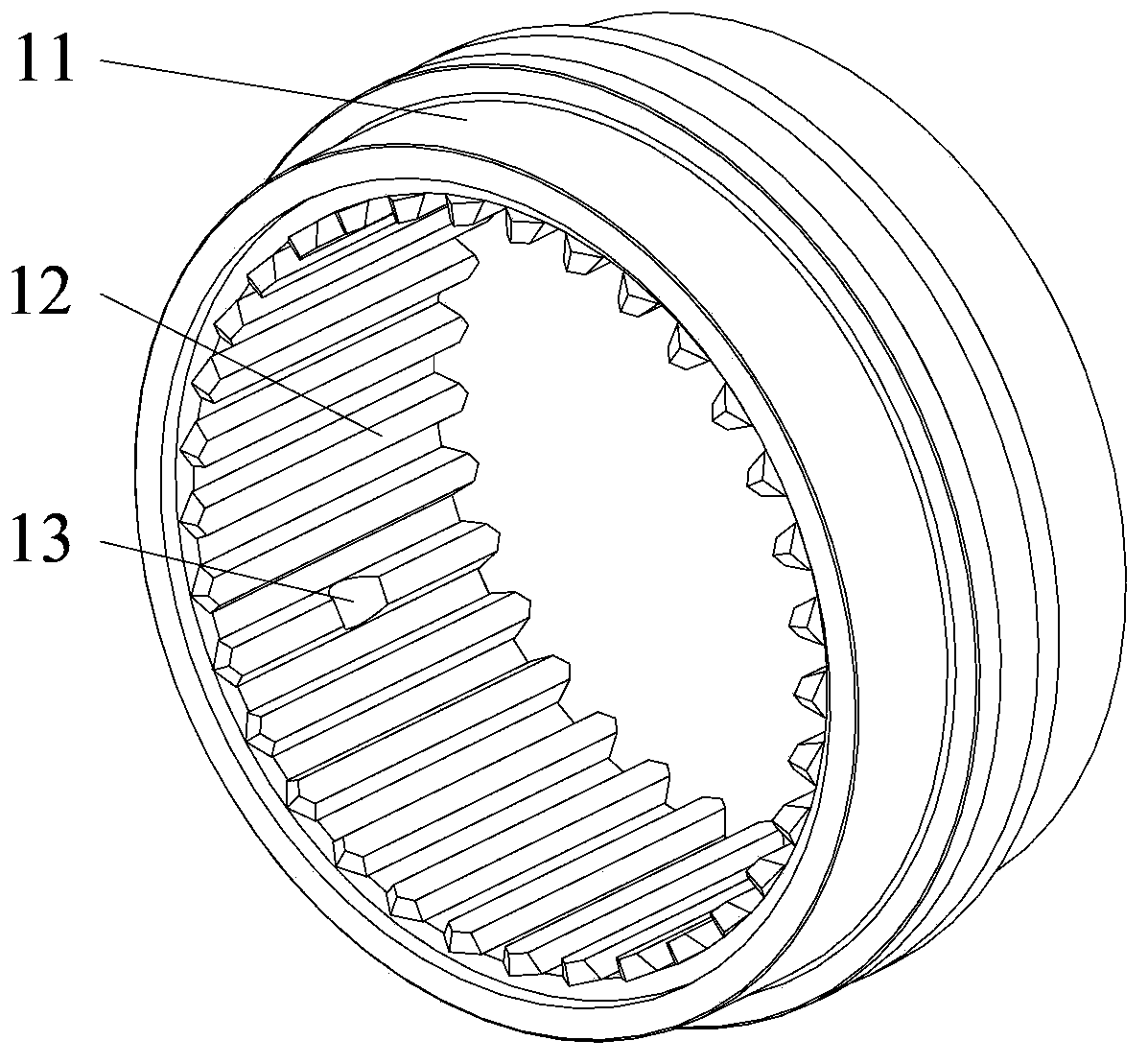

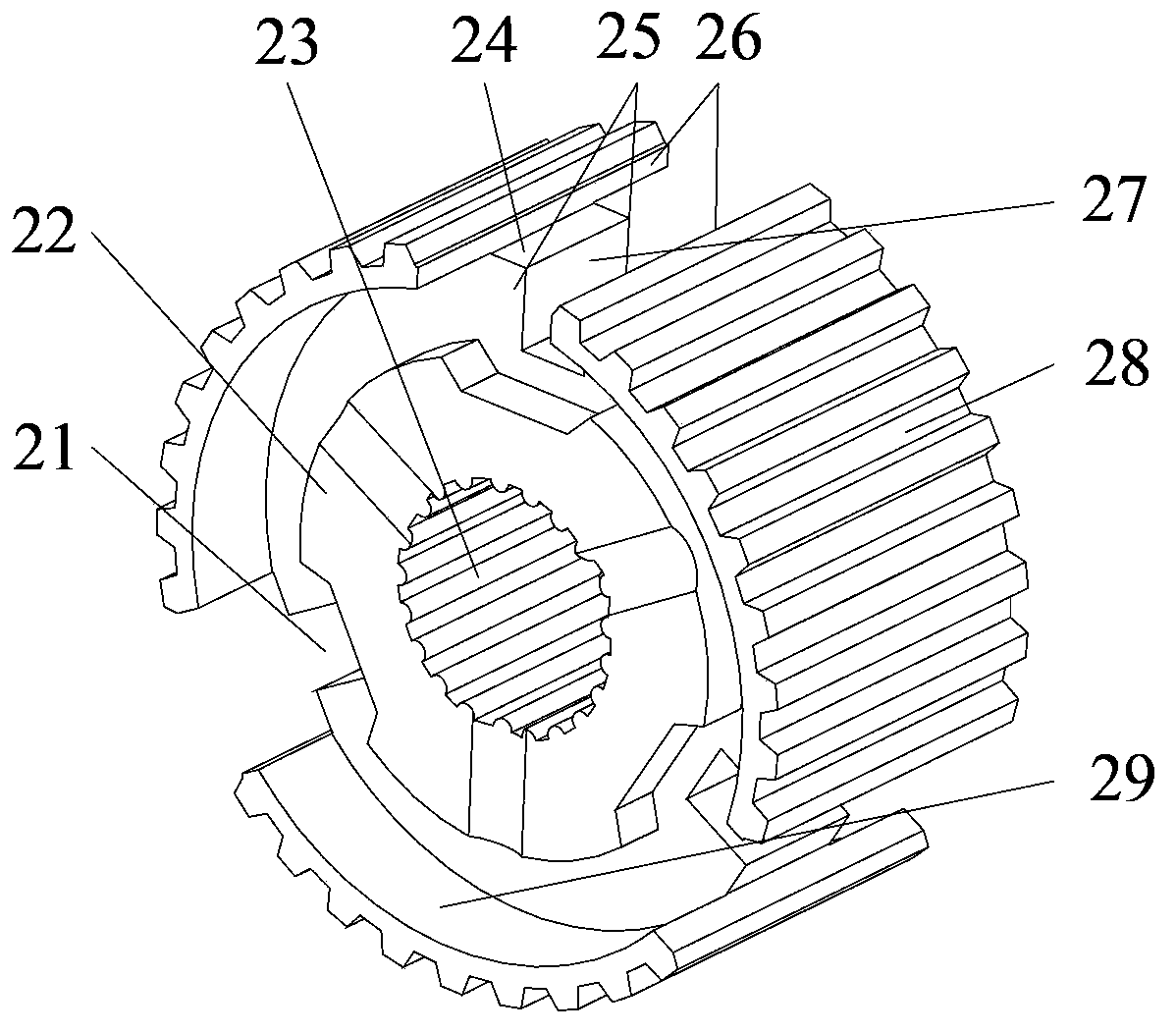

[0030] Such as Figures 1 to 12 As shown, the present invention proposes a booster synchronizer, which includes an adapter sleeve (1), a spline hub (2), a positioning slider (3), a synchronization ring (5) and a target gear (6), The adapter sleeve (1) is set on the spline hub (2), and a positioning slider (3) is provided between the adapter sleeve (1) and the spline hub (2); the spline hub (2) is provided with a concave The side of the groove (27) and the inner surface of the ring gear (29), the positioning slider (3) is provided with an axial end surface (32), and the target gear (6) is provided with an external friction cone (62), which is characterized in that the synchronization ring A booster ring (4) is provided between (5) and the splined hub (2), wherein:

[0031]The booster ring (4) is provided with a circular body (41), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com