Gear case fault diagnosis method based on non-timescale short-time phase demodulation

A technology of phase demodulation and fault diagnosis, which is applied in the testing of machine gears/transmission mechanisms, etc., can solve the problems of no signal detail research, needing time-scale signals, and inability to dig out fault features.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

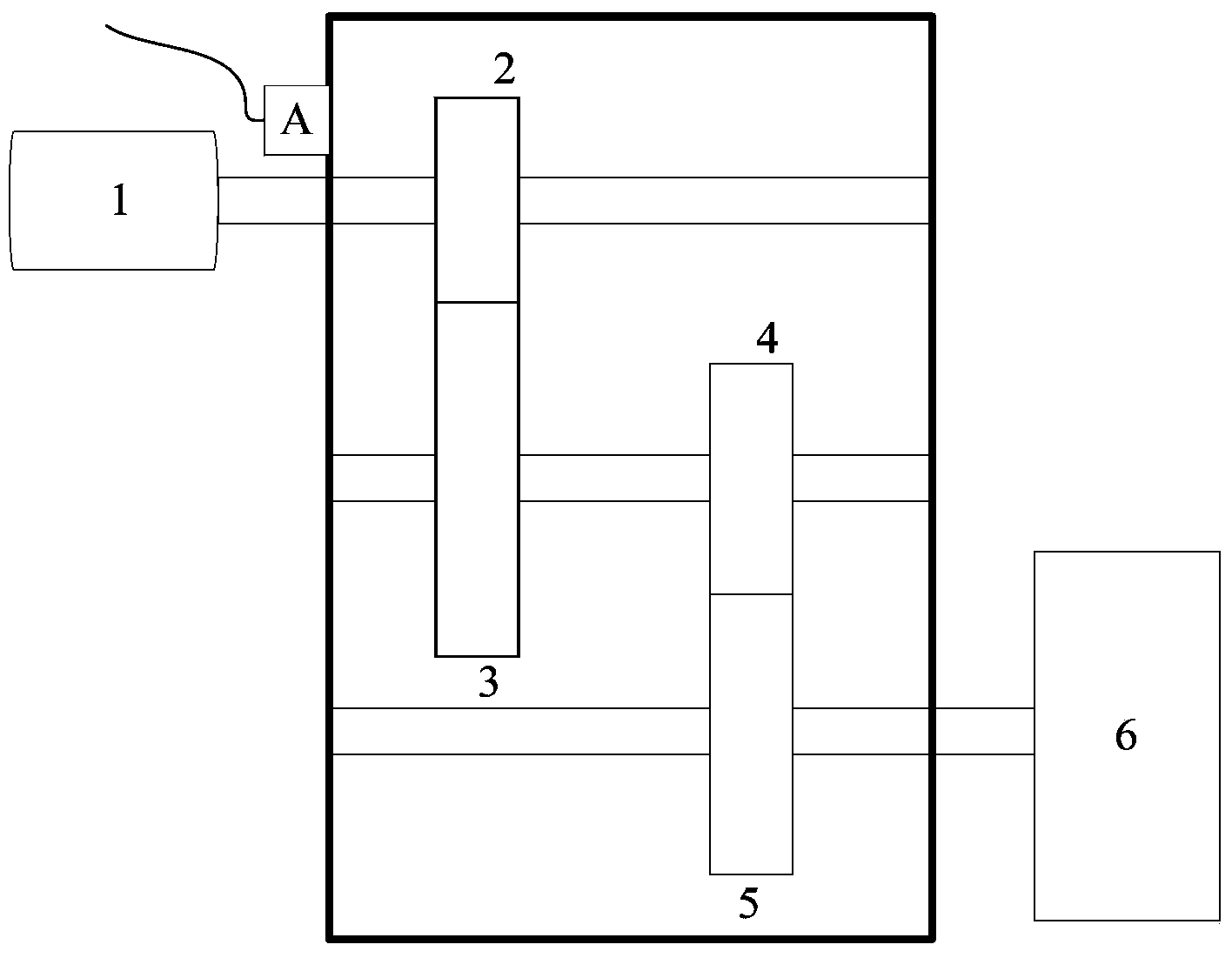

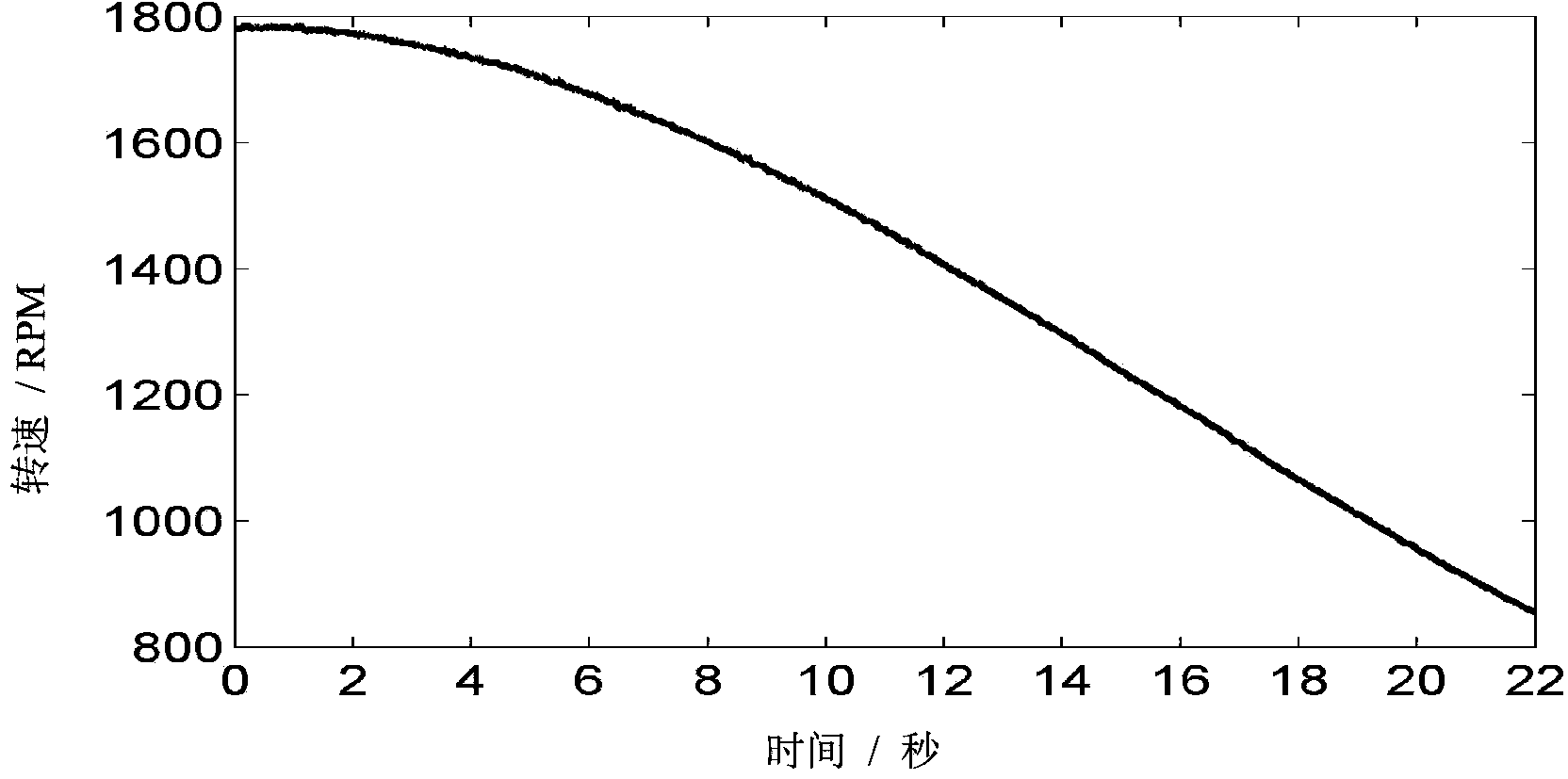

[0041] Taking the short-term phase demodulation of the gear test bench as an example during the deceleration process, the gearbox test bench is composed of a drive motor 1, a first gear 2, a second gear 3, a third gear 4, a fourth gear 5, and a brake 6 components ,Such as figure 1 As shown, the output shaft of the drive motor 1 is connected to the first gear 2, the first gear 2 meshes with the second gear 3, the second gear 3 and the third gear 4 are installed on the same transmission shaft, the third gear 4 and the fourth gear The gear 5 meshes, the transmission shaft of the fourth gear 5 is connected to the brake 6, and the first gear 2 has a peeling fault, such as figure 2 As shown, in the test, the vibration acceleration sensor A is adsorbed at the position close to the bearing end cover of the first gear 2 . In the test, the rotation speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com