Wide-viewing angle wave plate and application thereof

A wide viewing angle and wave plate technology, applied in optics, instruments, nonlinear optics, etc., can solve problems such as high material requirements and difficult manufacturing processes, and achieve the effects of reducing environmental hazards and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

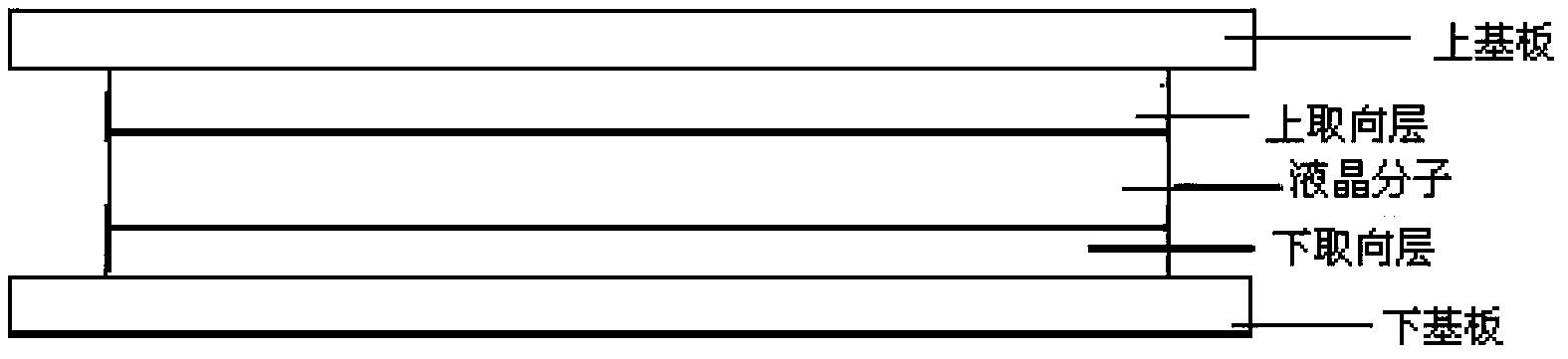

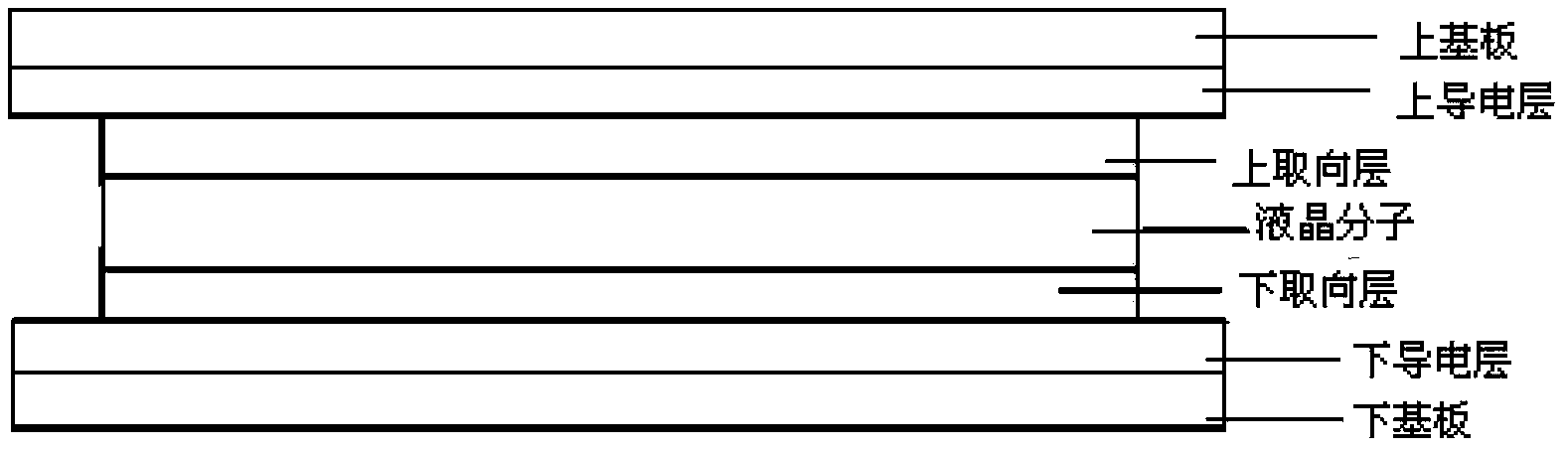

[0058] Prepare four pieces of ITO glass (obtained through commercial channels) for orientation treatment: two of them have a pretilt angle of 2° (A), and the other two have a pretilt angle of 88° (B). Lay one piece of glass A and one piece of B glass to make two pieces of 5μm liquid crystal cells.

[0059] The nematic liquid crystal used in the wide viewing angle wave plate is produced by Jiangsu Hecheng Display Technology Co., Ltd., model: HAG603200-000.

[0060] The liquid crystal is poured into a 5μm liquid crystal cell by capillary action, heated until clear, and then slowly cooled to room temperature, so that the liquid crystal molecules in the liquid crystal cell are arranged in an orderly manner. Bond two liquid crystal cells to form a λ / 2 wide viewing angle wave plate. It is required that the glass surfaces of B face inward, and ensure that the orientation direction of the glass surfaces of A is consistent.

[0061] Place the completed wide viewing angle wave plate b...

Embodiment 2

[0066] Prepare four pieces of ITO glass (obtained through commercial channels) for orientation treatment: two of them have a pretilt angle of 2° (A), and the other two have a pretilt angle of 88° (B). Lay one piece of glass A and one piece of B glass to make two pieces of 5μm liquid crystal cells.

[0067] The polymerizable nematic liquid crystal and photoinitiator used in the wide viewing angle wave plate are produced by Jiangsu Hecheng Display Technology Co., Ltd., and the models are WAWP005-01 and IE184. Wherein the photoinitiator content accounts for 0.1% by weight of the mixture. Heat and stir the mixture until it becomes clear and then stir evenly at room temperature. During the stirring process, the mixture needs to be protected from light, or operated under yellow light.

[0068] The liquid crystal is poured into a 5μm liquid crystal cell by capillary action, heated until clear, and then slowly cooled to room temperature, so that the liquid crystal molecules in the li...

Embodiment 3

[0075] Prepare two pieces of ITO glass (obtained through commercial channels) for orientation treatment: the pretilt angle is 1°. Lay two pieces of glass together to make a 10 μm antiparallel friction box.

[0076] The polymerizable nematic liquid crystal and photoinitiator used in the wide viewing angle wave plate are produced by Jiangsu Hecheng Display Technology Co., Ltd., and the models are WAWP005-01 and IE184. Wherein the photoinitiator content accounts for 0.1% by weight of the mixture. Heat and stir the mixture until it becomes clear and then stir evenly at room temperature. During the stirring process, the mixture needs to be protected from light, or operated under yellow light.

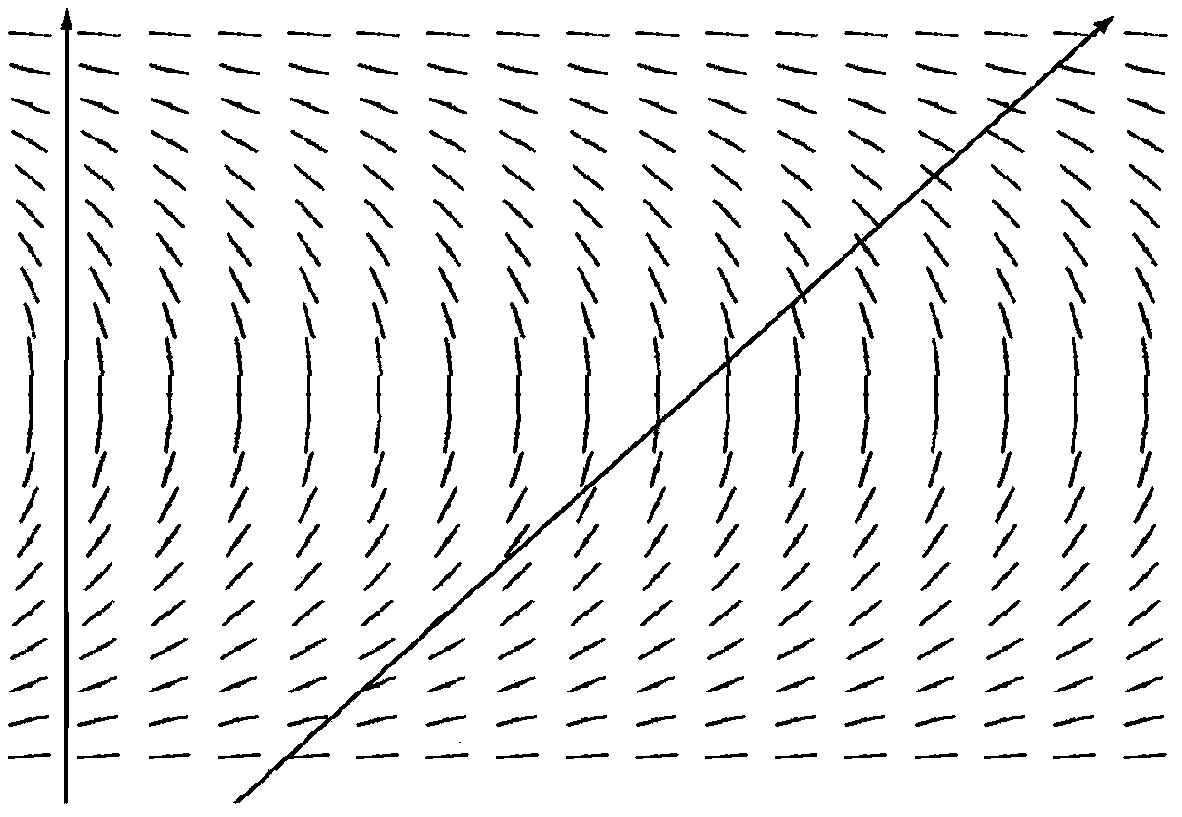

[0077] The liquid crystal is poured into a 10μm liquid crystal cell by capillary action, heated until clear, and then slowly cooled to room temperature, so that the liquid crystal molecules in the liquid crystal cell are arranged in an orderly manner. Apply a voltage of 1.3v and 1000Hz to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pretilt | aaaaa | aaaaa |

| Pretilt | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com