A Rapid Settling Overflow Tower Structure

A water tower, fast technology, applied in the direction of the settling tank, etc., can solve the problems of difficult sludge treatment and transportation, waste of time and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

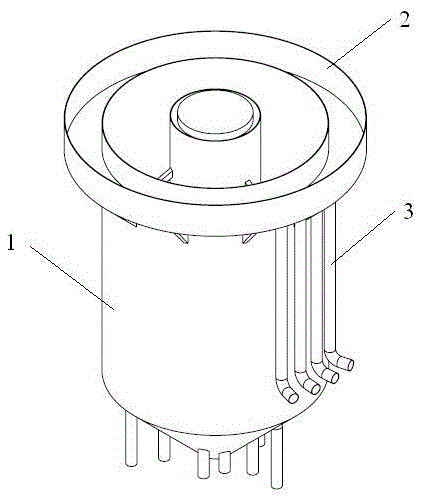

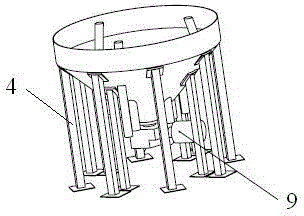

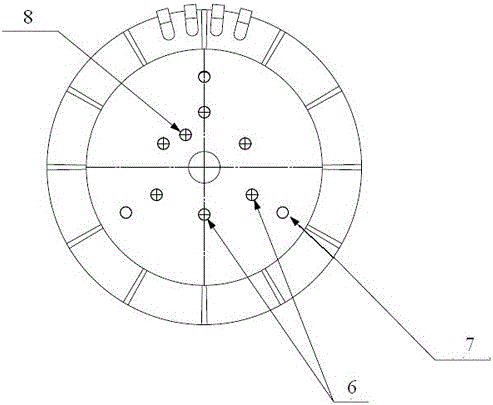

[0023] Such as figure 1 Shown, a kind of rapid sedimentation overflow tower structure, comprises a barrel body 1 of upper opening, and the bottom of barrel body 1 is fixed with bottom fixing bracket 4, and described barrel body 1 has the barrel bottom that a structure is conical, in described cone The mud outlet pipe 6, the sewage discharge pipe 8 and the mud inlet pipe 7 are connected on the bottom of the shaped barrel, the mud inlet end of the mud inlet pipe 7 is arranged at the bottom of the tapered barrel, and the mud outlet end of the mud inlet pipe 7 is stretched into In the barrel body 1 and higher than the arrangement of the barrel body edge at the top of the barrel body 1, a net cover and a top cover are provided above the mud outlet end of the mud inlet pipe 7;

[0024] The barrel also includes a stirring device, which is arranged at the center of the bottom of the barrel 1;

[0025] It also includes a clear water tank 2, which is arranged around the outer edge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com