Tool for cleaning wire rope

A technology for cleaning tools and wire ropes, applied in cleaning methods and utensils, cleaning methods using tools, cleaning flexible objects, etc., can solve problems such as increased viscosity and inability to cope with ropes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

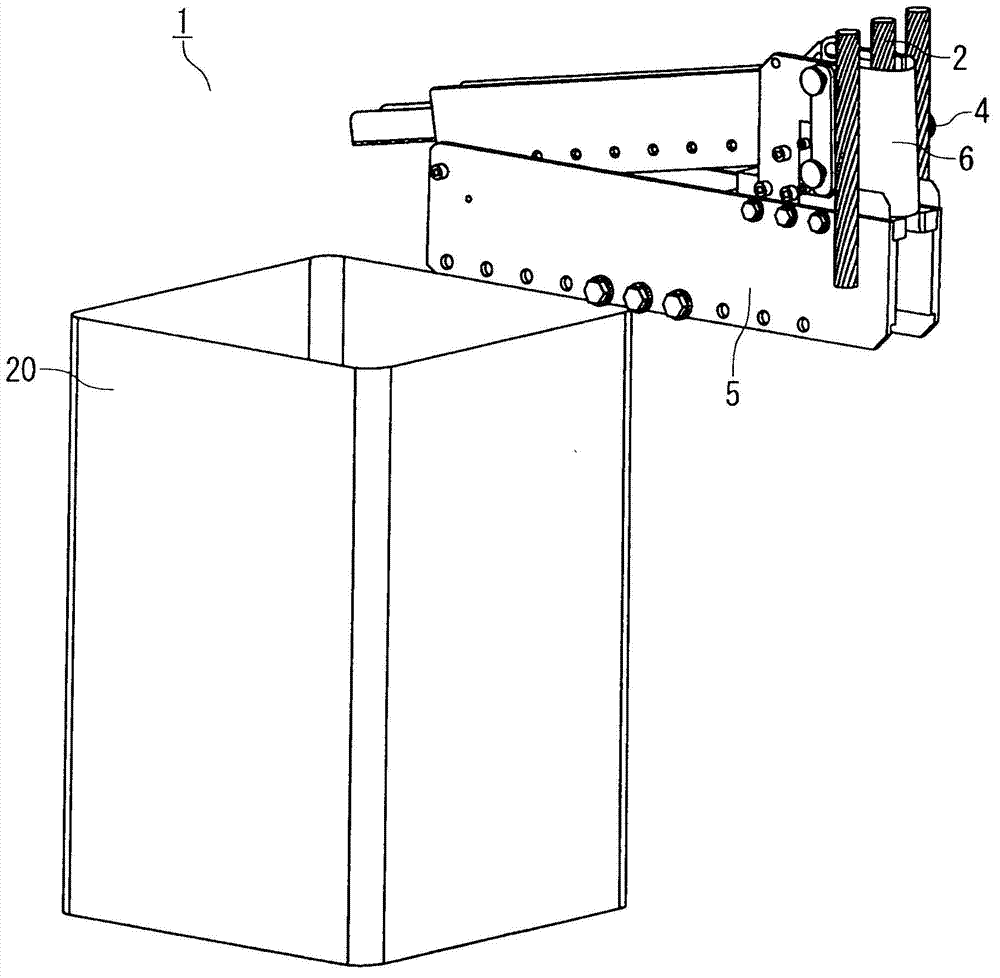

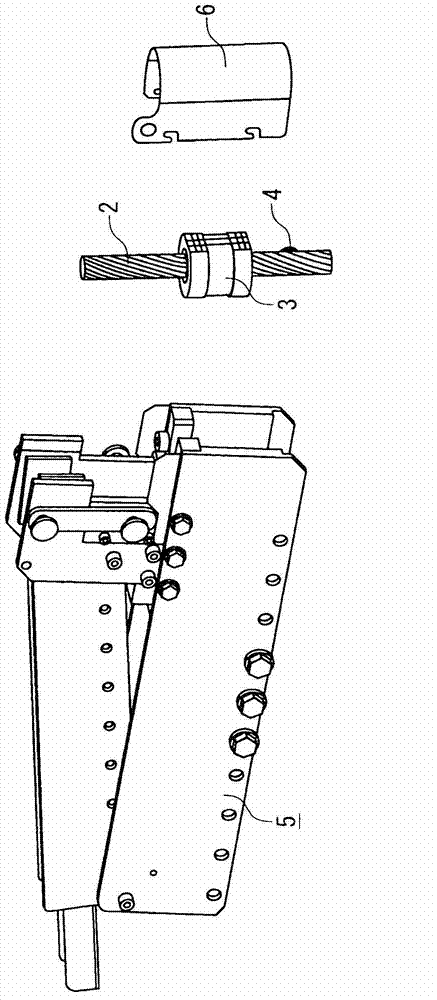

[0026] Embodiment 1 relates to a wire rope cleaning tool. The wire rope cleaning tool is composed of a wiper assembly, a rotary support member, a scraper, and a cover. The wiper assembly is composed of a resin wiper, a metal plate, and upper and lower reinforcement members. The resin The wiper has an inner surface that imitates the twisting of a steel wire rope, and is cut by a face offset from the center by a certain distance and parallel to the central axis of the steel wire rope; The inner peripheral shape of the upper and lower reinforcing members fixes the resin wiper and the metal plate by compressing the resin wiper and the metal plate in the up-down and center directions, and is cut off by a surface offset from the center by a certain distance; the rotation support The member supports the rotation of the wiper assembly; the scraper scrapes the grease attached to the wire rope.

[0027] Below, based on a perspective view of a wire rope cleaning tool figure 1 , as the ...

Embodiment approach 2

[0071] The wire rope cleaning tool of the second embodiment is a wire rope cleaning tool in which a cover plate is provided on the scraper of the wire rope cleaning tool of the first embodiment.

[0072] Below, the enlarged view based on the scraper of the wire rope cleaning tool is Figure 15 , the configuration and function of Embodiment 2 of the present invention will be described centering on the difference (cover plate) from the wire rope cleaning tool of Embodiment 1.

[0073] In addition, in Figure 15 In the same way as in Embodiment 1 figure 2 , Figure 11 The same reference numerals are attached to the same or corresponding parts.

[0074] Such as Figure 15 As shown, a cover plate 41 is provided above the vicinity of the overlapping section of the squeegee 7 . In addition, the bottom surface of the scraper 7 and the guide groove 8 , the side wall, and the inner surface of the cover plate 41 are coated with a low coefficient of friction by, for example, Teflon ...

Embodiment approach 3

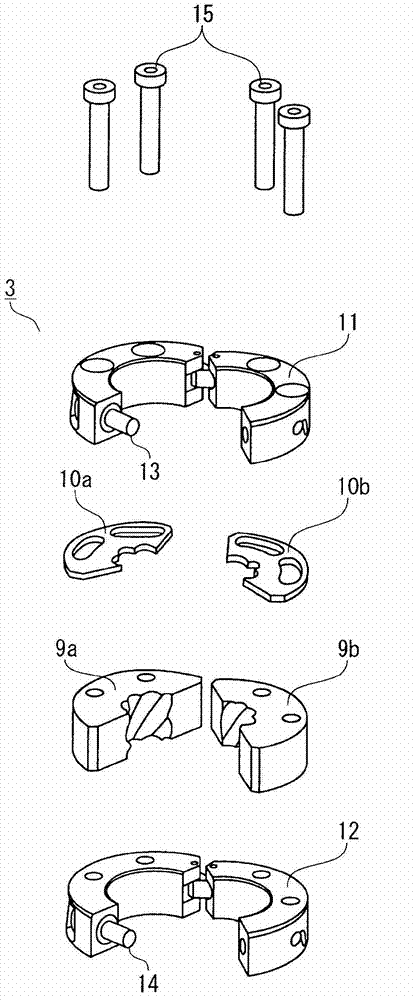

[0079] The wire rope cleaning tool of Embodiment 3 is formed by forming the wiper assembly of Embodiment 1 into such a structure that a resin wiper and a metal plate are sandwiched between annular first and second reinforcement members, and A leaf spring is provided between the inner peripheral sides of the first and second reinforcement members and the outer peripheral side of the resin wiper, and is compressed in vertical and central directions.

[0080] Hereinafter, centering on the wiper assembly, which is the difference from Embodiment 1, based on a perspective view of the components of the wiper assembly, that is, Figure 16 , to describe the structure and function of Embodiment 3 of the present invention.

[0081] The wiper assembly 50 is composed of a pair of resin wipers 51a, 51b (hereinafter collectively referred to as resin wiper 51), a pair of metal plates 52a, 52b (hereinafter collectively referred to as metal plate 52), and The first reinforcement member 53 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com