Automatic spray cooling device for centrifugal casting mold cylinder

An automatic spraying and cooling device technology, applied in the field of metallurgical centrifugal casting, can solve the problems of shortening the life of the casting mold, increasing the degree of chilling, and damaging the mold cylinder, achieving a high degree of automation, preventing local overheating, and improving casting quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

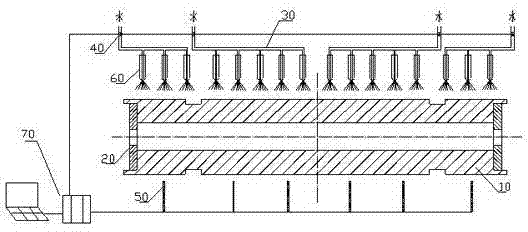

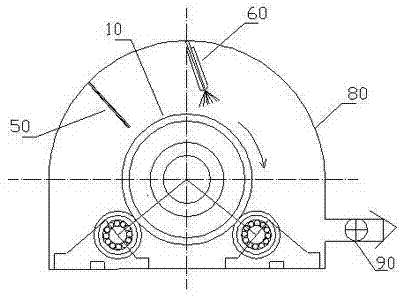

[0014] An automatic spray cooling device for a centrifugal casting mold cylinder, which is provided with a mold cylinder 10 and end caps 20 installed at both ends of the mold cylinder 10, and 4 sets of water collecting pipes 30 are arranged on the mold cylinder 10 to detect the temperature of the mold cylinder 10 The infrared thermometer 50 is arranged on the steam guide hood 80, and the lower part of the water collecting pipe 30 is equipped with a shower head 60, and the program analysis controller 70 for controlling the water flow solenoid valve 40 is arranged on the steam guide cover 80, An induced draft fan 90 capable of discharging steam is provided at the air outlet of the steam guiding cover 80 .

[0015] Each section of the cylinder 10 of the present invention can realize the real-time monitoring of temperature through the infrared thermometer 50 and the program analysis controller 70, and automatically adjust the spray flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com