Connecting-rod-type underactuated robot finger mechanism with all-rotational joints

A technology of robot fingers and rotating joints, applied in the field of anthropomorphic robots, can solve the difficulty and high cost of designing, assembling, manufacturing and maintaining the second knuckle, the difficulty in manufacturing and maintaining the slip joint, and the design size limit of the slip joint, etc. problems, to achieve the effect of easy production and maintenance, good adaptability and flexibility, and easy production and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

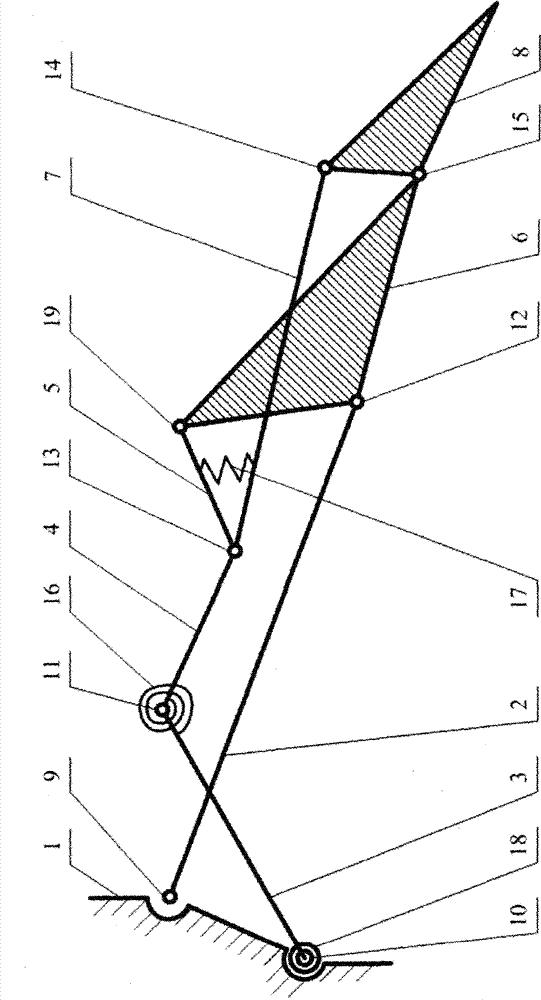

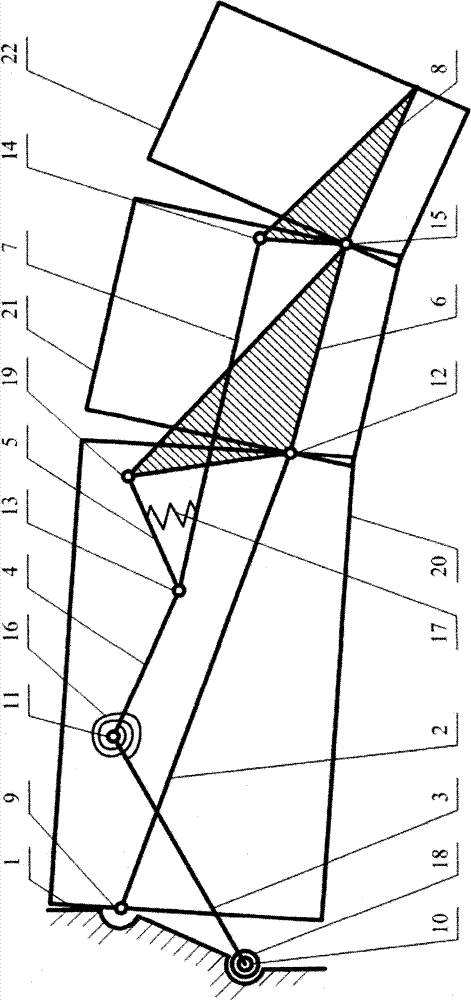

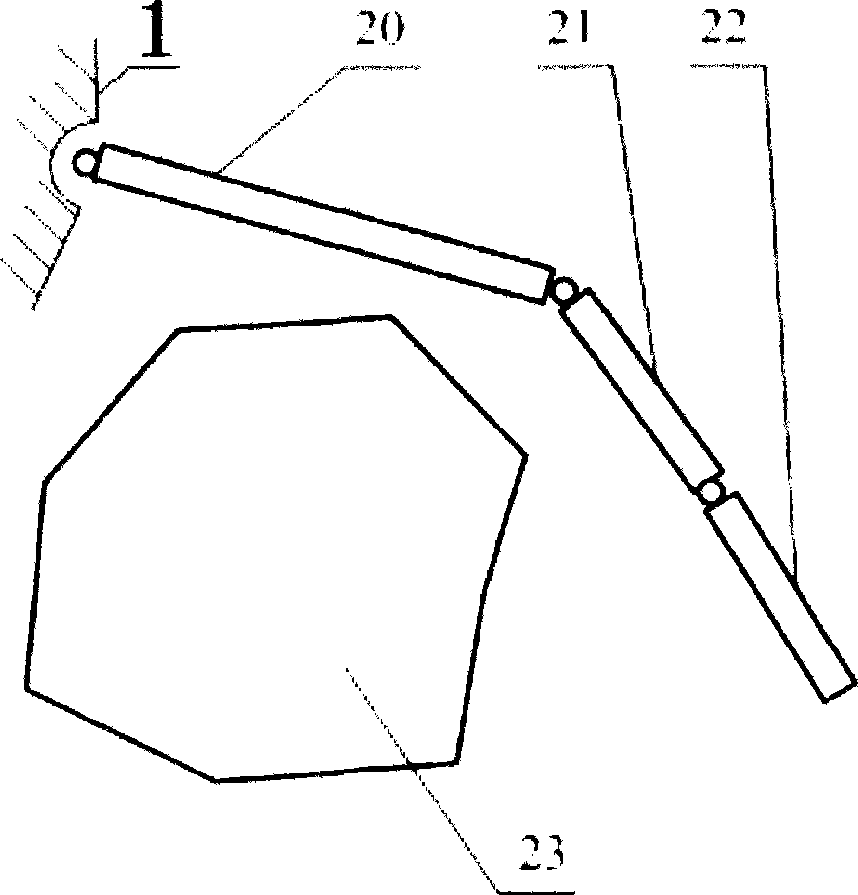

[0033] As shown in the figure, the full-rotation joint link type underactuated robot finger mechanism of the present invention includes a first connecting rod 1 (or base) and a drive motor and a reducer 18, and the upper part of the first connecting rod 1 is hinged to a forward and downward The protruding second connecting rod 2, the lower part of the first connecting rod 1 is hinged to a third connecting rod 3 protruding forward and upward driven by the motor and reducer 18, and the end of the third connecting rod 3 is hinged The fourth connecting rod 4 protruding forward and downward, the main return spring 16 is equipped between the third connecting rod 3 and the fourth connecting rod 4; the ends of the fourth connecting rod 4 are respectively hinged and extend forward and upward The fifth connecting rod 5 and the seventh connecting rod 7 protruding forward and downward, a secondary return spring 17 is fitted between the fifth connecting rod 5 and the seventh connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com