Movable distributing device

A material distributing device and mobile technology, which is applied in the fields of material yard equipment machinery, mineral processing, and sintering, can solve the problems that the mobile material distributing device cannot be used, the feeding equipment has high power, and cannot work normally, so as to achieve small vibration and transformation The effect of small amount of engineering and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

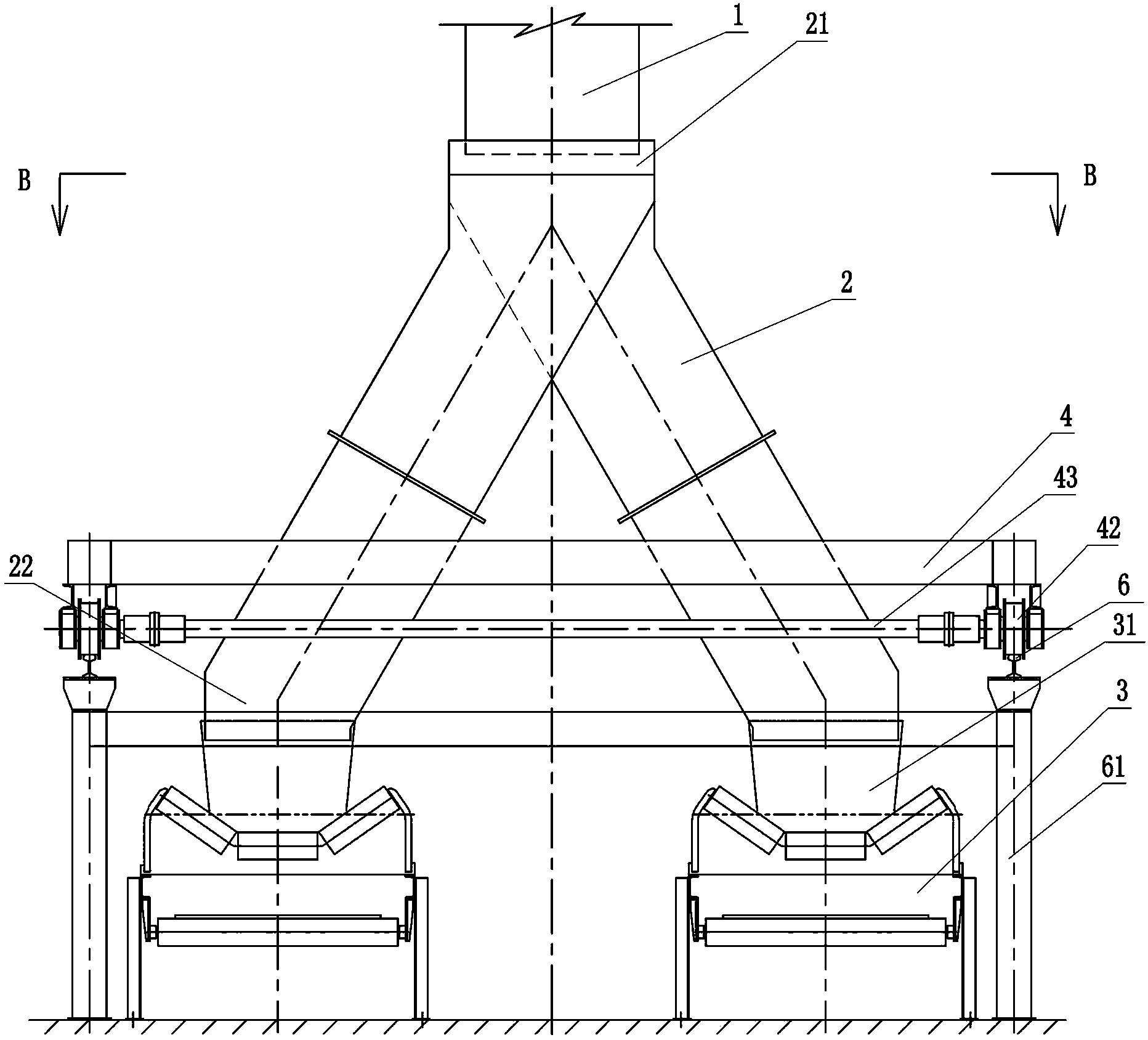

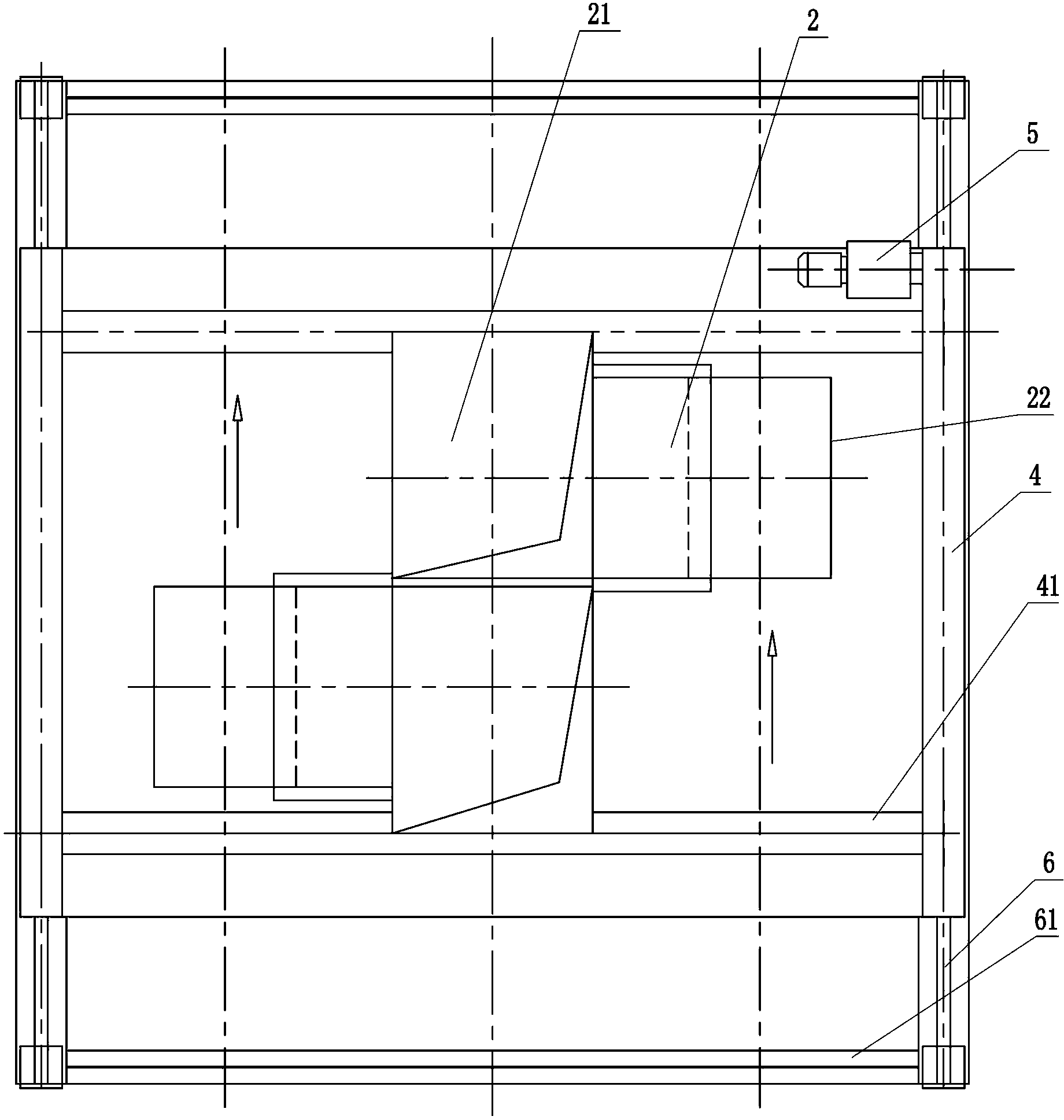

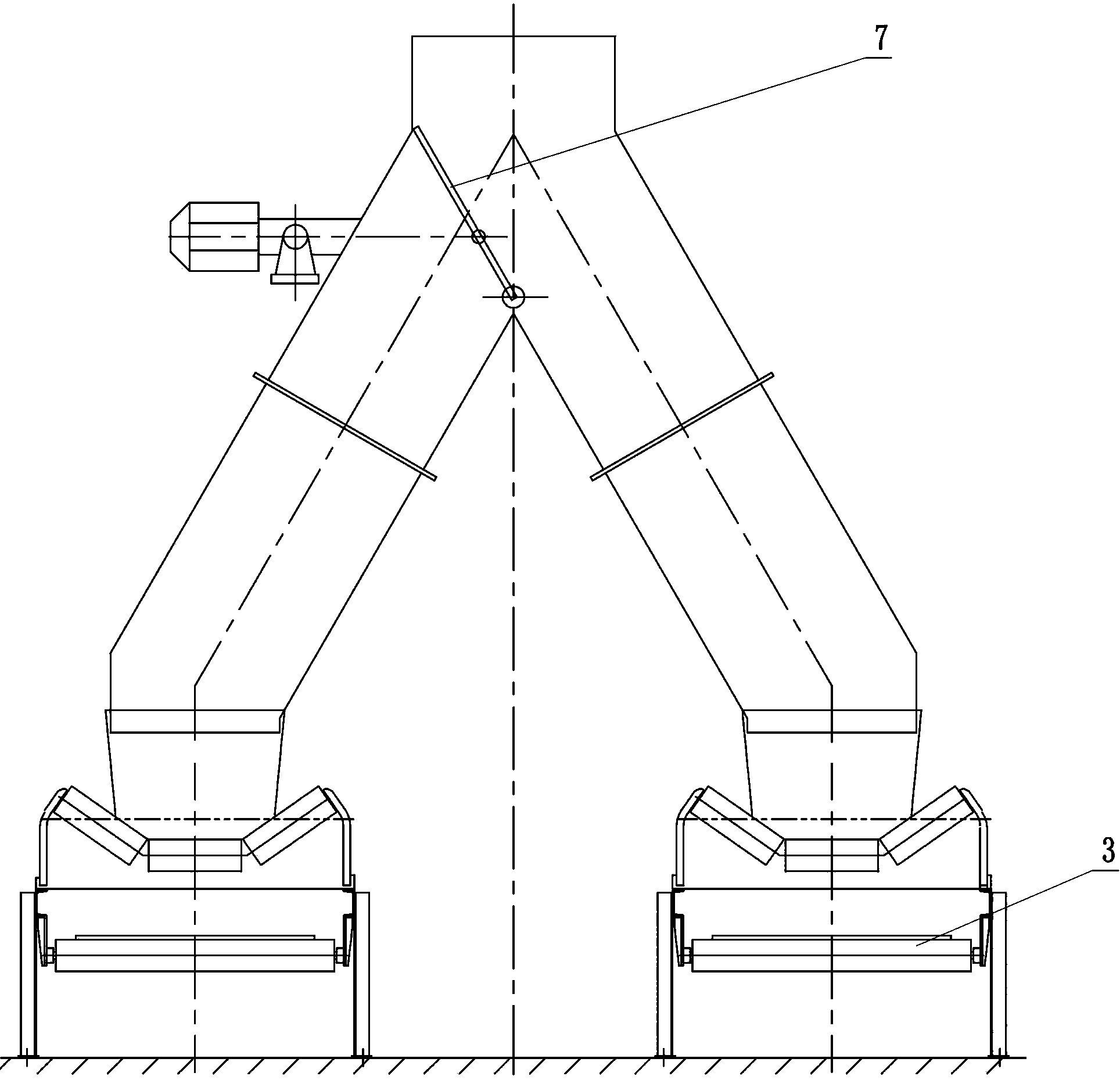

[0026] Such as figure 1 , figure 2 As shown, the mobile distributing device of this embodiment includes a fixed funnel 1, a mobile funnel group and a discharge mechanism 3, the fixed funnel 1 is fixedly connected with the feeding equipment, and the mobile funnel group is formed by connecting more than two mobile funnels 2, The discharging mechanism 3 corresponds to the quantity of the moving funnel 2 . The feeding ports 21 of the moving funnels 2 in the moving funnel group are arranged along the discharging direction of the discharging mechanism 3 , and the discharging ports 22 of each moving funnel 2 are connected with a corresponding discharging mechanism 3 . The moving funnel set is equipped with a driving mechanism for driving the moving funnel set to mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com