Recovery method of hexane in the production process of high density polyethylene

A high-density polyethylene, production process technology, applied in the direction of organic chemistry, fractional condensation purification/separation, etc., can solve the problems of hexane material loss, hexane pollution of the environment, etc., to reduce the amount of N2, solve environmental pollution, good technology effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

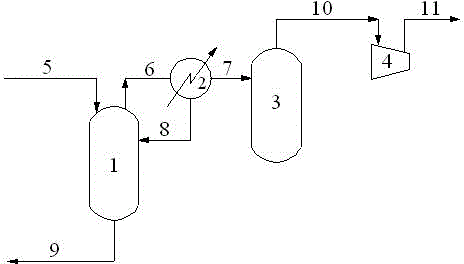

[0019] use figure 2 In the shown process, the operating temperature of the hexane exhaust gas of the hexane condenser is reduced from 35°C to -8°C; the operating pressure is 0.01 MPaG. The operating temperature of the catalyst preparation tank is 35°C; the operating pressure is 0.01 MPaG. The operating temperature of the compressor suction tank is -8°C; the operating pressure is 0.001MPaG; the operating temperature of the gas compressor is -8°C rising to 90°C; the operating pressure is increased from 0.001MPaG to 0.40MPaG. The present invention utilizes the existing compressor suction tank and gas compressor equipment to directly send the hexane exhaust gas to the hexane condenser for condensation, the liquid phase of the condensed part is returned to the catalyst preparation tank for reuse, and the hexane of the uncondensed part is discharged The process flow that the suction tank of the air feed compressor is pressurized and then enters the drying gas system, which reduces...

Embodiment 2

[0021] Same as [Example 1], using figure 2 In the process, only the operating conditions were changed, and the operating temperature of the hexane exhaust gas of the hexane condenser was reduced from 38°C to -6°C; the operating pressure was 0.012MPaG. The operating temperature of the catalyst preparation tank is 38° C.; the operating pressure is 0.012 MPaG. The operating temperature of the compressor suction tank is -6°C; the operating pressure is 0.002MPaG; the operating temperature of the gas compressor is -6°C rising to 90°C; the operating pressure is increased from 0.002MPaG to 0.40MPaG. The present invention utilizes the existing compressor suction tank and gas compressor equipment to directly send the hexane exhaust gas to the hexane condenser for condensation, the liquid phase of the condensed part is returned to the catalyst preparation tank for reuse, and the uncondensed hexane exhaust gas The technological process of sending the compressor suction tank to pressuriz...

Embodiment 3

[0023] Same as [Example 1], using figure 2 In the process, only the operating conditions were changed, and the operating temperature of the hexane exhaust gas of the hexane condenser was reduced from 45°C to -5°C; the operating pressure was 0.015MPaG. The operating temperature of the catalyst preparation tank is 45°C; the operating pressure is 0.015MPaG. The operating temperature of the compressor suction tank is -5°C; the operating pressure is 0.003MPaG; the operating temperature of the gas compressor is -5°C rising to 90°C; the operating pressure is increased from 0.003MPaG to 0.40MPaG. The present invention utilizes the existing compressor suction tank and gas compressor equipment to directly send the hexane exhaust gas to the hexane condenser for condensation, the liquid phase of the condensed part is returned to the catalyst preparation tank for reuse, and the hexane of the uncondensed part is discharged The process flow that the suction tank of the air feed compressor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com