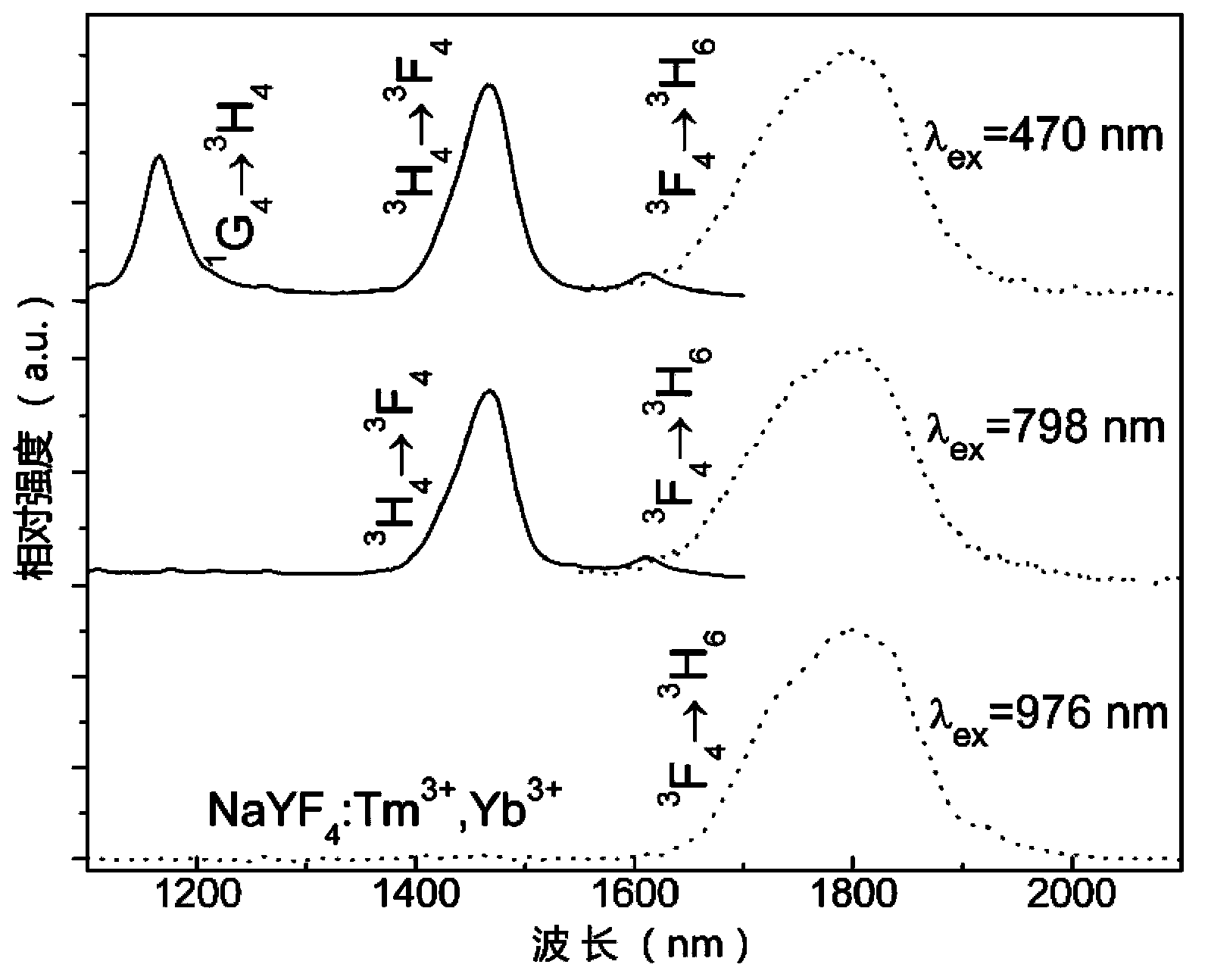

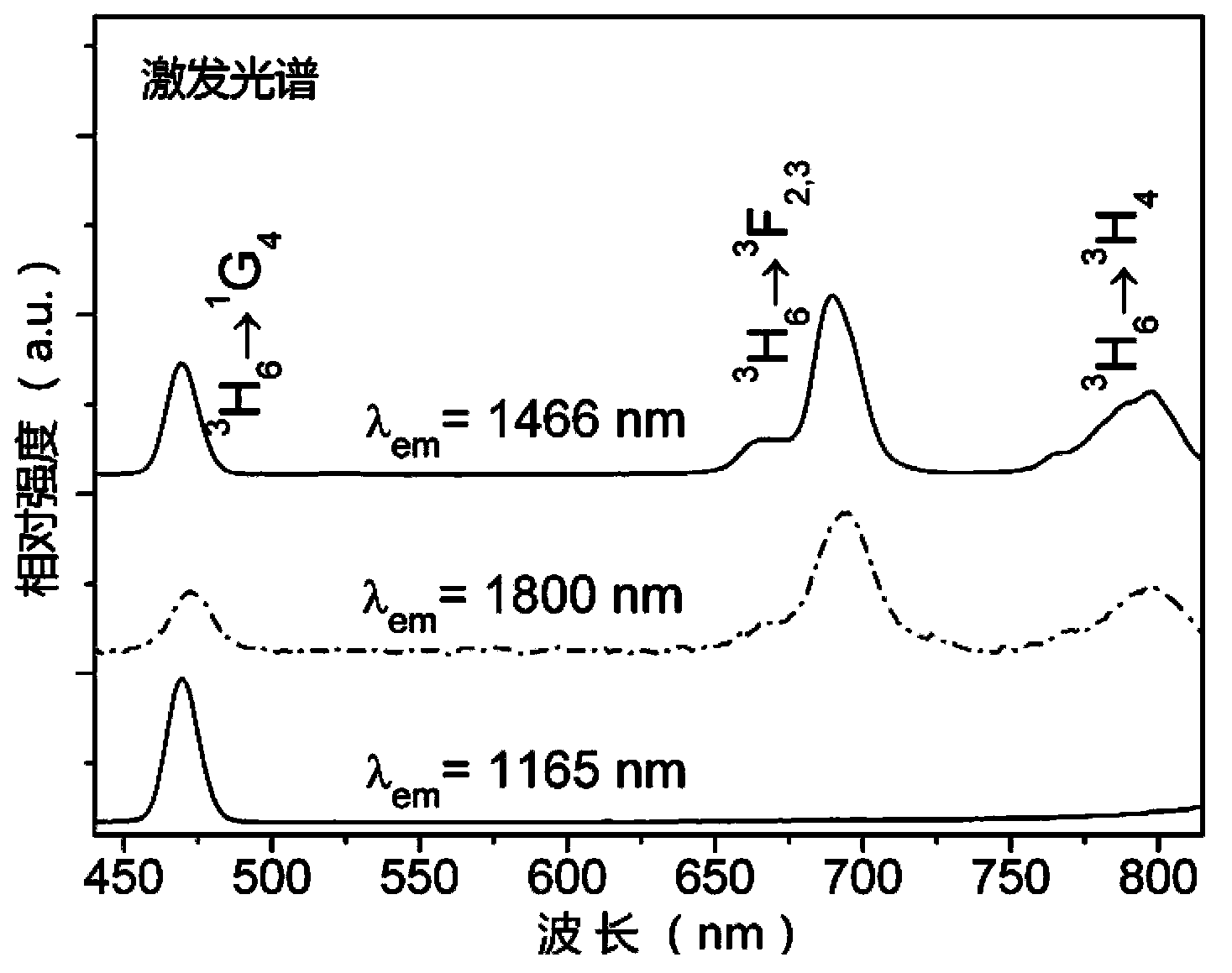

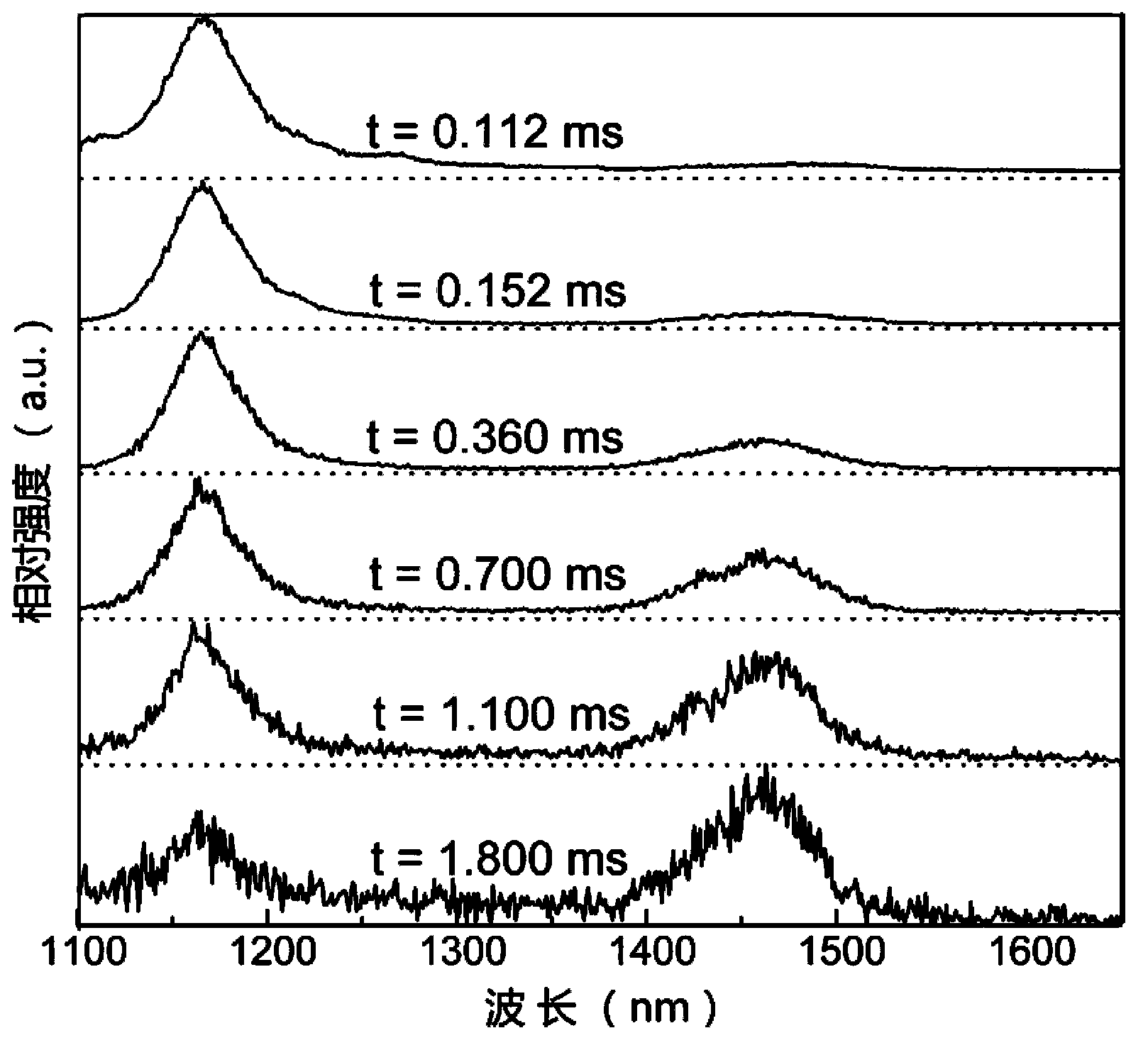

Tm<3+>-doped three-photon infrared quantum cutting material and preparation method thereof

A quantum tailoring, infrared technology, applied in luminescent materials, chemical instruments and methods, photovoltaic power generation and other directions, can solve the problem of rare reports of rare earth ion single-doped system infrared quantum tailoring materials, and achieve the effect of improving low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Prepare four copies of the following samples: Accurately weigh 0.5589g of yttrium oxide (Y 2 o 3 ) and 0.0096g thulium oxide (Tm 2 o 3 ), dissolved in an appropriate amount of hot concentrated nitric acid, and prepared to a concentration of 0.05mol.L -1 Y(NO 3 ) 3 solution and Tm(NO 3 ) 3 solution; then accurately weigh 0.2100g sodium fluoride (NaF) and 0.5668g ammonium bifluoride (NH 4 HF 2 ), all dissolved in an appropriate amount of deionized aqueous solution to obtain NaF and NH 4 HF 2 mixed solution; under the uniform mixing effect of magnetic stirring, the prepared Y(NO 3 ) 3 and Tm(NO 3 ) 3 Slowly and completely add NaF and NH to the mixed solution 4 HF 2 In the mixed solution; adjust the pH of the mixed solution to 3 by dropping an appropriate amount of ammonia water to form a precursor suspension. After stirring for 30 minutes, move the formed precursor suspension to a stainless steel reaction kettle with a volume of 50ml and a Teflon liner , th...

Embodiment 2

[0030] Accurately weigh 0.5631g of yttrium oxide (Y 2 o 3 ) and 0.0024g thulium oxide (Tm 2 o 3 ), dissolved in an appropriate amount of hot concentrated nitric acid, and prepared to a concentration of 0.05mol.L -1 Y(NO 3 ) 3 solution and Tm(NO 3 ) 3 solution; then accurately weigh 0.2100g sodium fluoride (NaF) and 0.5668g ammonium bifluoride (NH 4 HF 2 ), all dissolved in an appropriate amount of deionized aqueous solution to obtain NaF and NH 4 HF 2 mixed solution; under the uniform mixing effect of magnetic stirring, the prepared Y(NO 3 ) 3 and Tm(NO 3 ) 3 Slowly and completely add NaF and NH to the mixed solution 4 HF 2 In the mixed solution; adjust the pH of the mixed solution to 2 by dropping an appropriate amount of ammonia water to form a precursor suspension. After stirring for 30 minutes, move the formed precursor suspension to a stainless steel reaction kettle with a volume of 50ml and a Teflon liner , the filling degree is 70%. Crystallize in an ov...

Embodiment 3

[0032] Accurately weigh 0.3952g of yttrium oxide (Y 2 o 3 ) and 0.2894g thulium oxide (Tm 2 o 3 ), dissolved in an appropriate amount of hot concentrated nitric acid, and prepared to a concentration of 0.05mol.L -1 Y(NO 3 ) 3 solution and Tm(NO 3 ) 3 solution; then accurately weigh 0.2100g sodium fluoride (NaF) and 0.5668g ammonium bifluoride (NH 4 HF 2 ), all dissolved in an appropriate amount of deionized aqueous solution to obtain NaF and NH 4 HF 2 mixed solution; under the uniform mixing effect of magnetic stirring, the prepared Y(NO 3 ) 3 and Tm(NO 3 ) 3 Slowly and completely add NaF and NH to the mixed solution 4 HF 2 In the mixed solution; adjust the pH of the mixed solution to 6 by dropping an appropriate amount of ammonia water to form a precursor suspension. After stirring for 30 minutes, move the formed precursor suspension to a stainless steel reaction kettle with a volume of 50ml and a Teflon liner , the filling degree is 85%. Crystallize in an ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com