Combined type shield tunneling machine

A shield machine and compound technology, applied to mining equipment, earthwork drilling, tunnels, etc., can solve the problems of reducing construction efficiency, increasing tool change frequency, shortening service life, etc., to improve construction efficiency, simplify configuration, extend The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

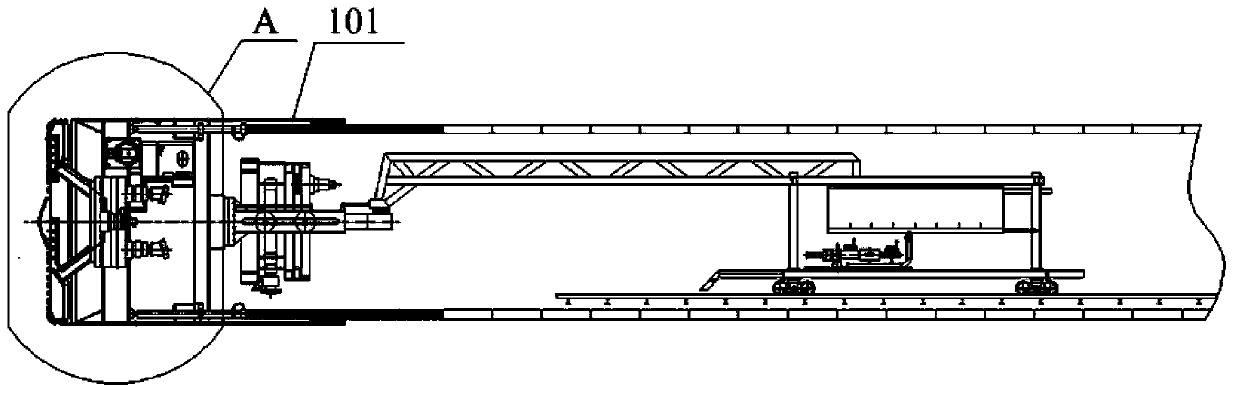

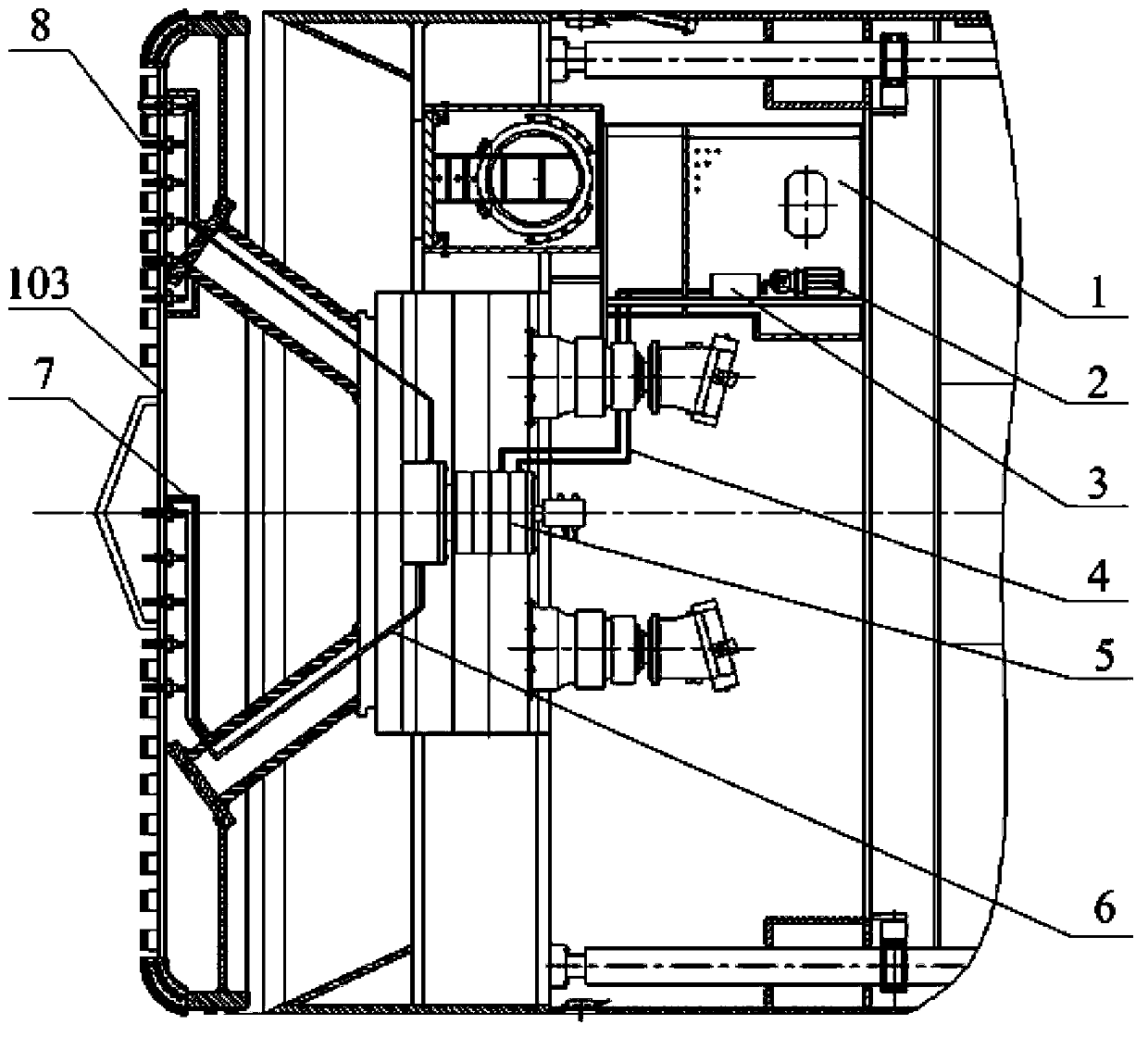

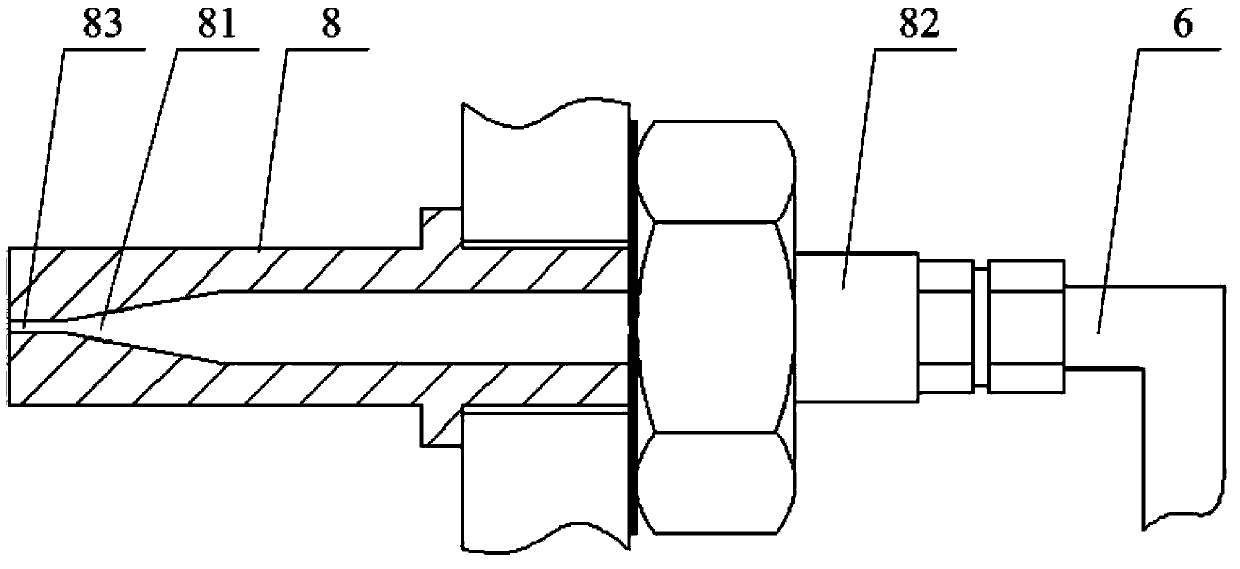

[0041] Please refer to Figure 1 to Figure 4 , figure 1 It is a structural schematic diagram of a compound shield machine with a high-pressure fluid jet grooving device according to the first embodiment of the present invention; figure 2 for figure 1 The enlarged schematic diagram of area A in the middle; image 3 It is a schematic diagram of the nozzle structure in the first embodiment of the present invention; Figure 4 Schematic diagram of the high-pressure fluid jet grooving trajectory.

[0042] The high-pressure fluid jet slotting device is arranged at the front of the shield body 101 for jetting high-pressure fluid to the front of the shield body 101 in the same direction as the shield body 101 advances.

[0043] The high-pressure fluid jet grooving device provided in this embodiment includes a liquid storage tank 1, a pump 2, a booster 3, a first pipeline 4, a central rotary joint 5, a second pipeline 6, a sheath 7 and a nozzle 8, The components are sequentially c...

Embodiment approach 2

[0063] Image 6 It is a partial structural schematic diagram of a composite shield machine with an abrasive high-pressure fluid jet grooving device according to the second embodiment of the present invention; Figure 7 for Image 6 An enlarged schematic view of the structural details of the nozzle and the abrasive supply device in area B of ; Figure 8 for Figure 7 An enlarged schematic view of the structural details of the abrasive suction pipe and the abrasive throttle cock in middle region C; Figure 9 It is a schematic diagram of the nozzle structure in the second embodiment of the present invention.

[0064] This embodiment describes a high-pressure plunger pump directly driven by a drive motor and an abrasive high-pressure fluid jet grooving composite shield machine. The high-pressure fluid is a mixture of high-pressure water and abrasive, and the nozzle is an abrasive with an abrasive mixing function. Mixing nozzle 14.

[0065] Such as Image 6 As shown, the abra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com