Shaft seal of nuclear grade centrifugal fan

A centrifugal fan and shaft sealing technology, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of running wear and heating, poor gas sealing, grease outflow, etc., and achieves longer life, less wear and tear. Effect of heat generation and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

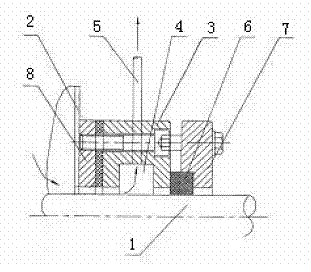

[0011] Such as figure 1 The shown shaft seal of a nuclear-grade centrifugal fan includes a transmission shaft 1 and a fan volute 2, and the right side of the fan volute 2 is provided with a diversion return cavity 4 wrapped by a diversion return cavity shell 3, The fan volute 2 and the flow return chamber 4 and the drive shaft 1 are in clearance fit, and one end of the return air pipe 5 is also connected to the flow return air chamber 4, and the other end of the return air pipe 5 is connected to the air inlet , the right end of the diversion return air cavity 4 is provided with a sealing packing 6, the sealing packing 6 is closely matched with the transmission shaft 1, a sealing cover 7 is installed on the sealing packing 6, and the sealing cover 7 is also connected with the diversion return air cavity housing 3 Fixedly connected, the fan volute 2 is also equipped with a reinforcing plate 8 on the side connected to the diversion return air cavity housing 3, and the reinforcing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com