Testing device and testing method for water tightness of cable

A test device, water tightness technology, applied in liquid tightness measurement using liquid/vacuum degree, by measuring the increase and deceleration rate of the fluid, by detecting the appearance of the fluid at the leak point, etc., it can solve the problem of unable to detect the cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

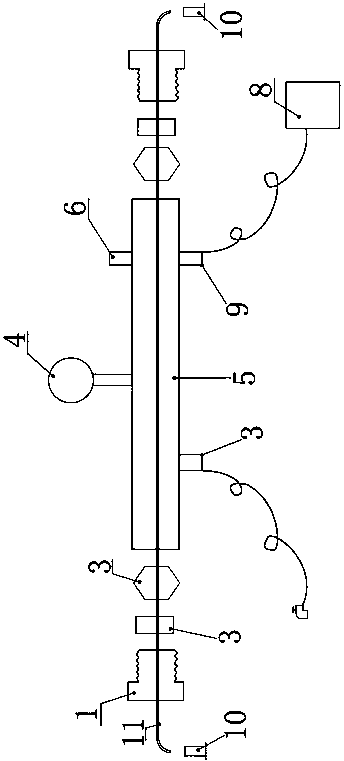

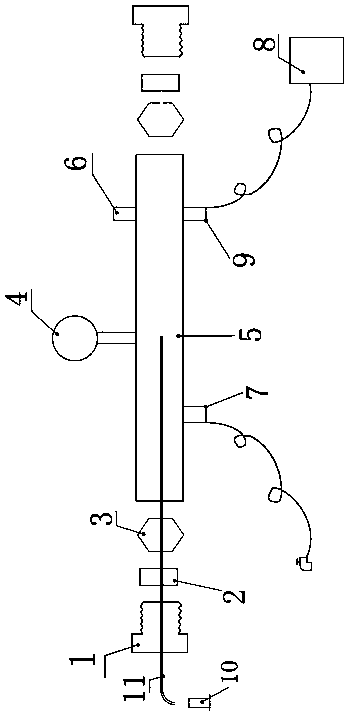

[0023] Such as figure 1 , 2 As shown, a cable watertightness test device includes a fastening nut 1, a sealing rubber ring 2, a flange 3, a pressure gauge 4, a pressure chamber 5, a pressure relief valve 6, a water source interface 7, a pressure device 8, and a pressure interface 9 , measuring cylinder 10, the pressure chamber 5 is a tubular body, and the pipe body of the pressure chamber 5 is respectively provided with a pressure gauge 4, a pressure relief valve 6, a water source interface 7, and a pressure interface 9, respectively on the two ends of the pressure chamber 5 pipe body A flange 3 is screwed and fixed, and the fastening nut 1 with a wire passing hole or the fastening nut 1 without a wire passing hole is screwed to the flange 3 at one end of the pressure chamber 5 through a sealing rubber ring 2. The fastening nut 1 of the wire hole or the fastening nut 1 without the wire hole is screwed to the flange 3 at the other end of the pressure chamber 5 through the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com