Method for judging breaking strength of coating fabric membrane material

A technology of coated fabrics and judgment methods, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of large differences between prediction results and test results, and achieve the effect of simple method, convenient operation, and accurate prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Use the coated fabric membrane material, and cut the coated fabric membrane material into a strip-shaped test piece, with a length of 1000mm and a width of 50mm;

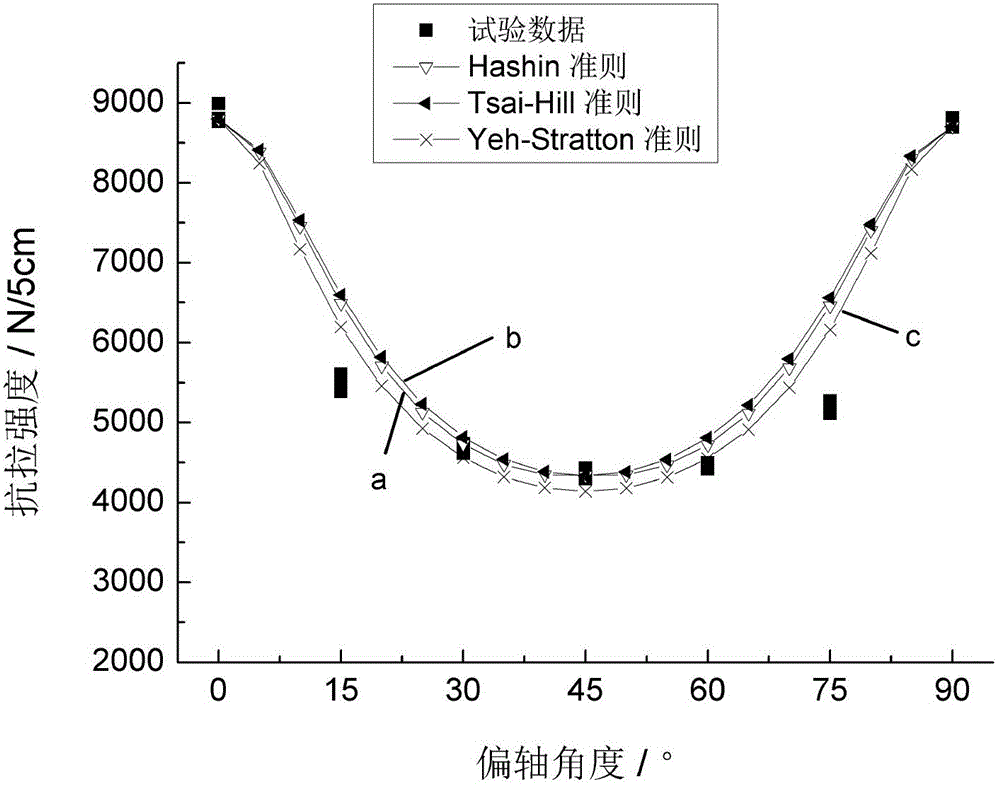

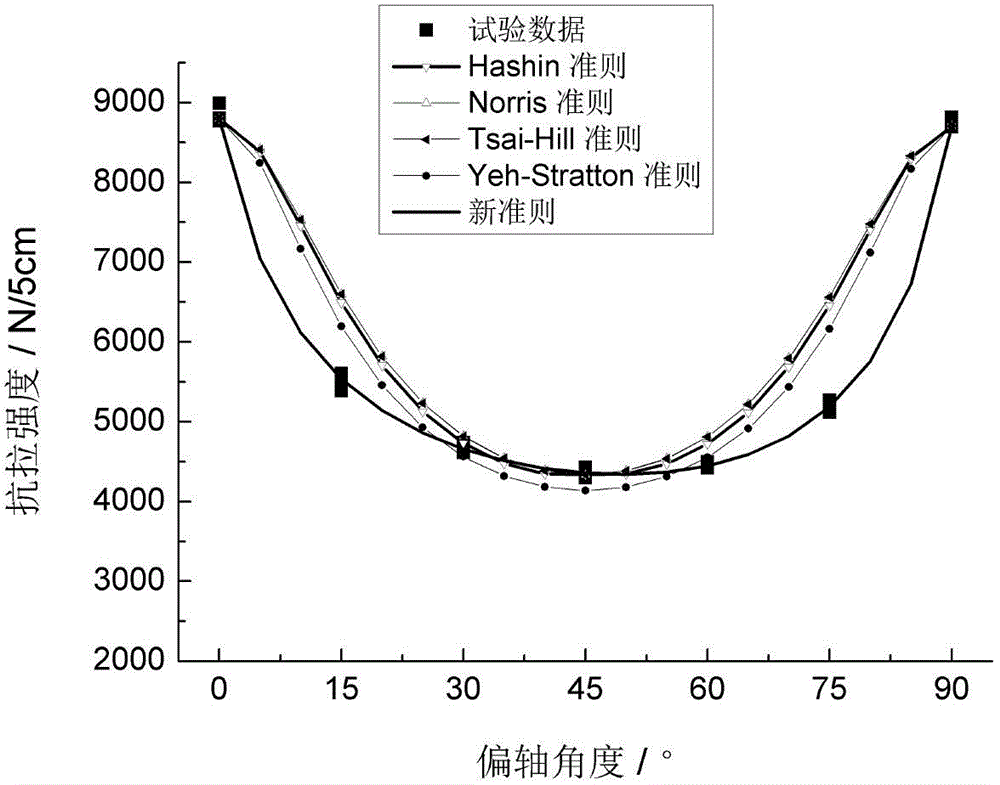

[0035] (2) According to the traditional off-axis tensile test method, use a conventional material tensile testing machine to conduct two sets of tensile tests, select one set of cutting direction and fiber direction to form an angle θ of 45 degrees, and another set of cutting direction and fiber direction The direction is at an angle θ of 30 degrees, and the tensile force F is applied along the cutting direction of the material until it is destroyed during the test;

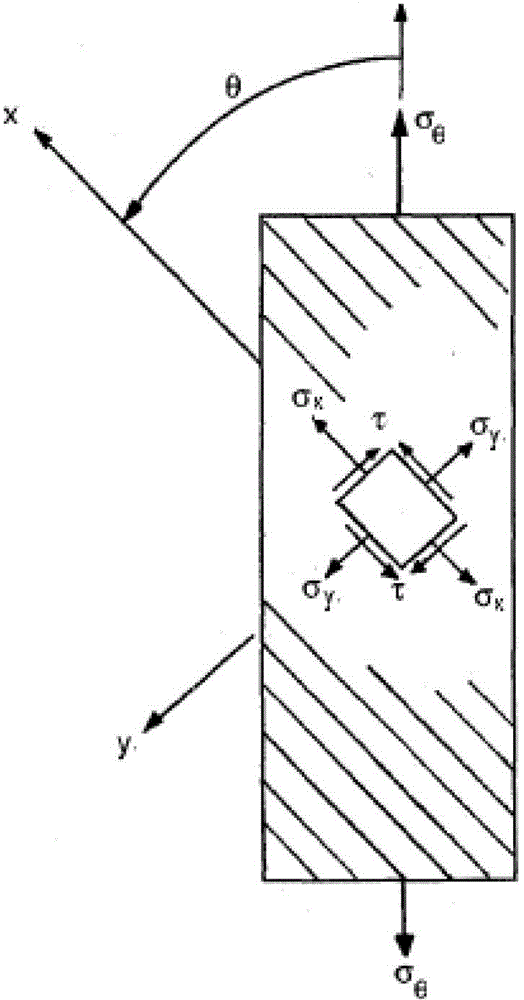

[0036] (3) When the tensile force F is gradually increased until the coated fabric membrane material is damaged, the normal stress and shear stress of the coated fabric material are as follows: figure 1 As shown, at this time, the normal stress and shear stress of the two main axis directions of the coated fabric membrane material, namely t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com