Cyanide-containing orange-yellow azo dye

A technology of orange-yellow azo dyes, applied in azo dyes, organic dyes, reactive dyes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The specific structure of Embodiment 1 is as follows:

[0035]

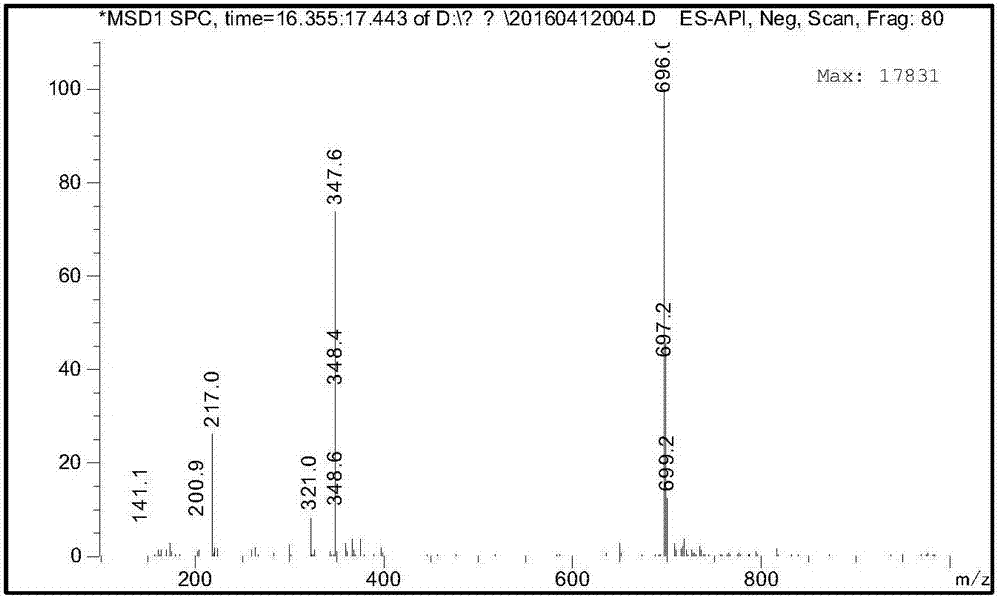

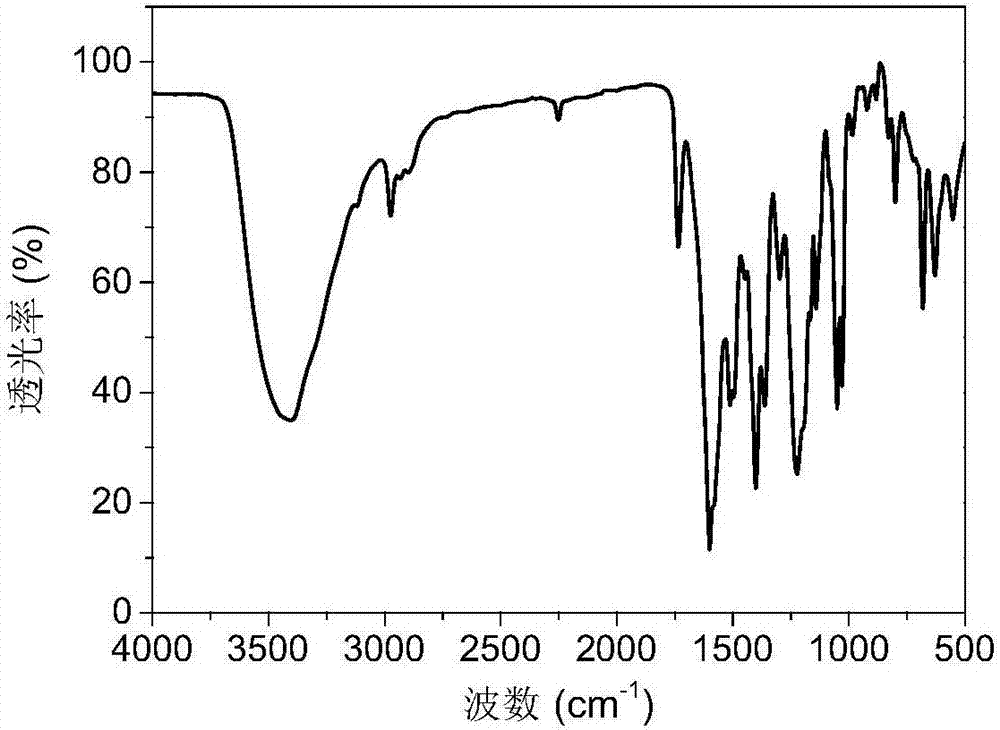

[0036] Condensation reaction of cyanuric chloride: Add 1.90g cyanuric chloride (0.0103mol) and 20g small ice cubes in a 250mL beaker, and beat for 30min to milky. The aqueous solution (0.01mol, 98%) containing 3.11g m-phenylenediamine-4,6-bissulfonic acid was slowly added dropwise to the above-mentioned beating solution, and reacted at 0~5℃, using 10% Na 2 CO 3 The pH value of the solution is adjusted to be 4~5, and the end point of the reaction is detected by TLC (the developing solvent is isobutanol: n-propanol: ethyl acetate: water = 2:4:1:3, v / v, the R of the product f Value is 0.74), after the reaction is completed, add 0.75g glycine (0.01mol), raise the temperature to 20~30℃, use 10% Na 2 CO 3 The pH value of the solution is controlled between 6 and 7, after 3 to 4 hours of reaction, TLC detects the end of the reaction (developing solvent is n-butanol: isopropanol: ethyl acetate: water = 2:4:1:3, v / v , R...

Embodiment 2

[0040] The specific structure of Embodiment 2 is as follows:

[0041]

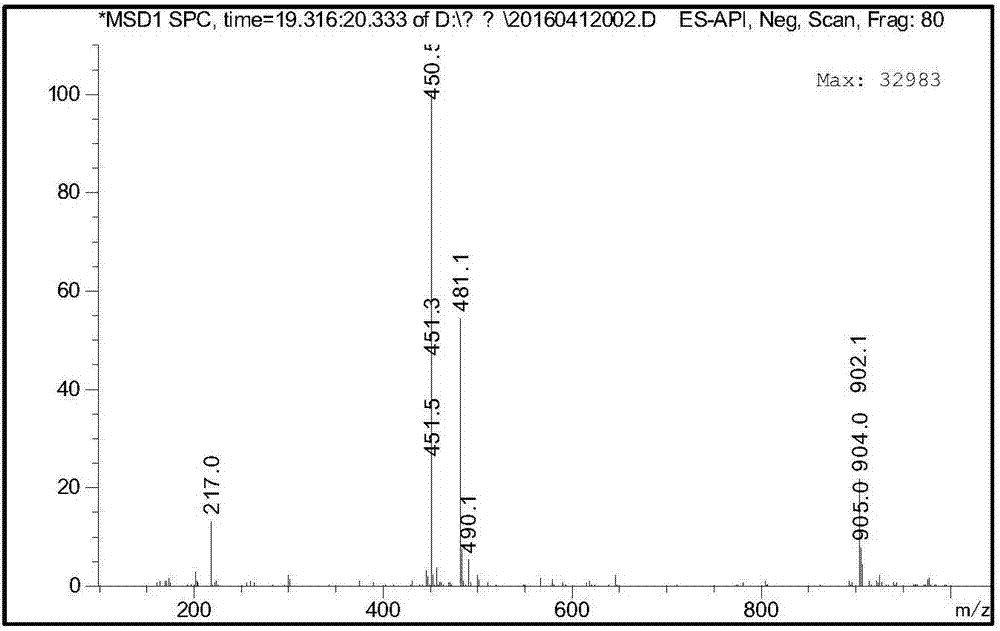

[0042] Condensation reaction of cyanuric chloride: Add 1.90g cyanuric chloride (0.0103mol) and 20g small ice cubes in a 250mL beaker, and beat for 30min to milky. The aqueous solution (0.01mol, 98%) containing 3.11g m-phenylenediamine-4,6-bissulfonic acid was slowly added dropwise to the above-mentioned beating solution, and reacted at 0~5℃, using 10% Na 2 CO 3 The pH value of the solution is adjusted to 4~5, and the end point of the reaction is detected by TLC (the developing solvent is isobutanol: n-propanol: ethyl acetate: water = 2:4:1:3, v / v, the R of the product f Value is 0.74), after the reaction is completed, add 0.89g alanine (0.01mol), raise the temperature to 20~30℃, use 10% Na 2 CO 3 The pH value of the solution is controlled between 6 and 7, after 3 to 4 hours of reaction, the end of the reaction is detected by TLC (developing solvent is n-butanol: isopropanol: ethyl acetate: water = 2:4:1:3, v / v ...

Embodiment 3

[0046] The specific structure of Embodiment 3 is as follows:

[0047]

[0048] Condensation reaction of cyanuric chloride: Add 1.90g cyanuric chloride (0.0103mol) and 20g small ice cubes in a 250mL beaker, and beat for 30min to milky. The aqueous solution (0.01mol, 98%) containing 3.11g m-phenylenediamine-4,6-bissulfonic acid was slowly added dropwise to the above-mentioned beating solution, and reacted at 0~5℃, using 10% Na 2 CO 3 The pH value of the solution is adjusted to 4~5, and the end point of the reaction is detected by TLC (the developing solvent is isobutanol: n-propanol: ethyl acetate: water = 2:4:1:3, v / v, the R of the product f Value is 0.74), after the reaction is completed, add 1.17g valine (0.01mol), raise the temperature to 20~30℃, use 10% Na 2 CO 3 The pH value of the solution is controlled between 6 and 7, after 3 to 4 hours of reaction, TLC detects the end of the reaction (developing solvent is n-butanol: isopropanol: ethyl acetate: water = 2:4:1:3, v / v );

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com