Heat balance monitoring method for coal-fired power plant

A coal-fired power plant, heat balance technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of tension deviation of belt scales, inability to monitor thermal balance status, lack of space layout conditions for coal feeder platforms, etc., and achieve strong applicability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

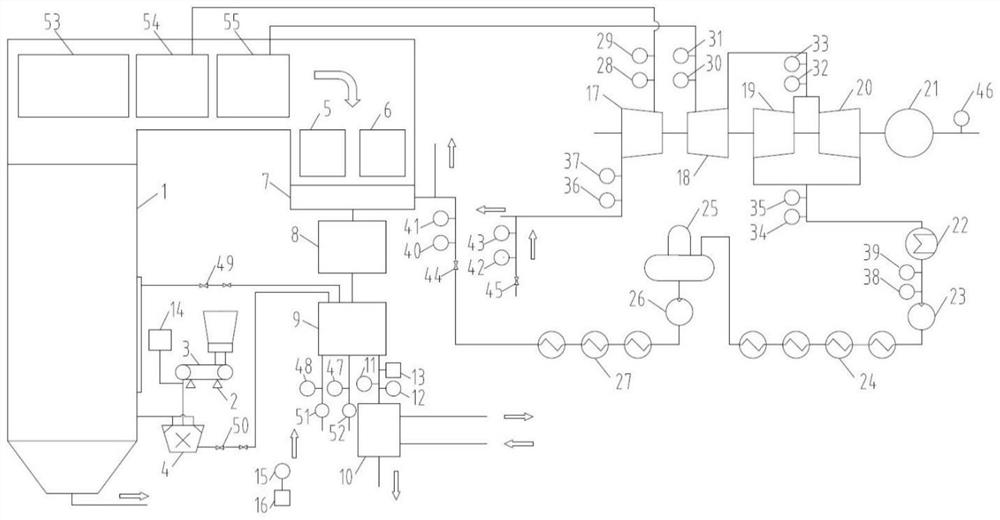

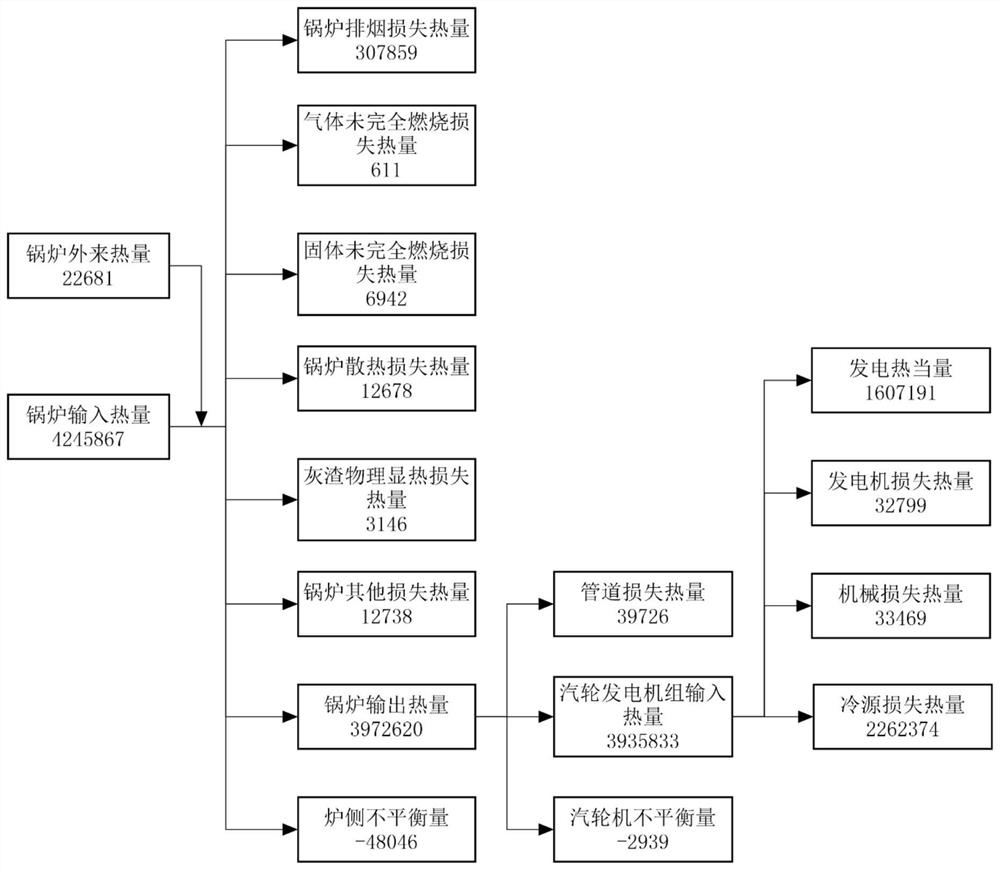

[0210] as figure 1 A certain subcritical 350MW unit shown is an example, and the thermal balance detection method of the present invention is specifically described, including the following steps:

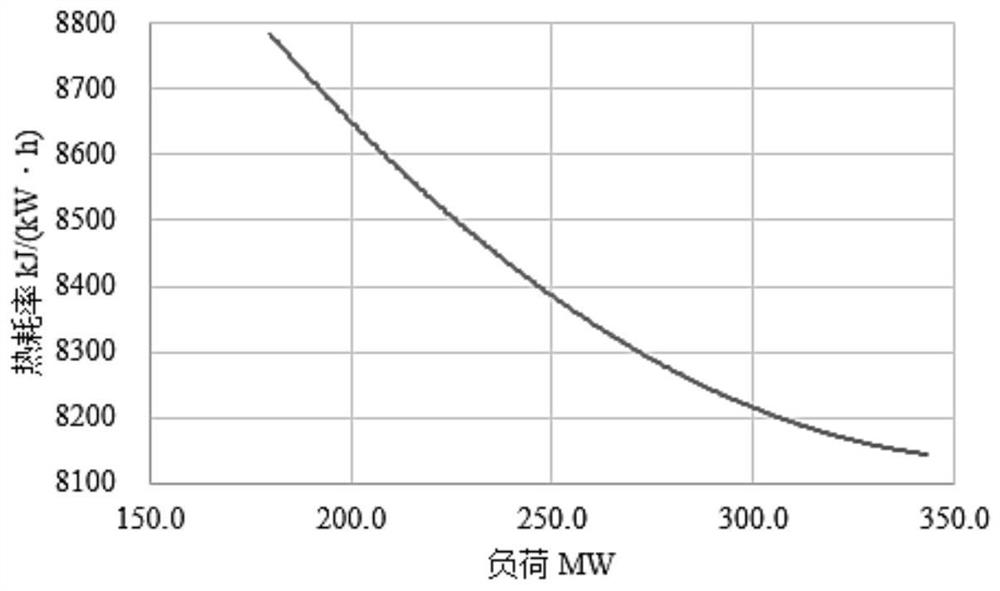

[0211] S1: Based on the DCS / SIS system, collect a set of unit load, evaporation, power generation, exhaust gas oxygen, exhaust gas temperature, exhaust gas CO, fly ash combustibles, and air temperature at the inlet of the air preheater every five minutes , The data of the atmospheric environment humidity, as shown in Table 1, determine a load range with 5% of the rated load 350MW as the range, the obtained load range is shown in Table 2, and perform statistical sorting to count the operation of each load range Hour;

[0212] S2: According to the statistical data, calculate the boiler efficiency η of each load interval, the specific results are shown in Table 1,

[0213] Calculate the weighted thermal efficiency η of a single unit gl :

[0214] n gl =(60441*92.60%+72536*92.42%+...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com