Accelerated corrosion test device capable of simulating marine atmospheric environment

An accelerated corrosion test, marine and atmospheric technology, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

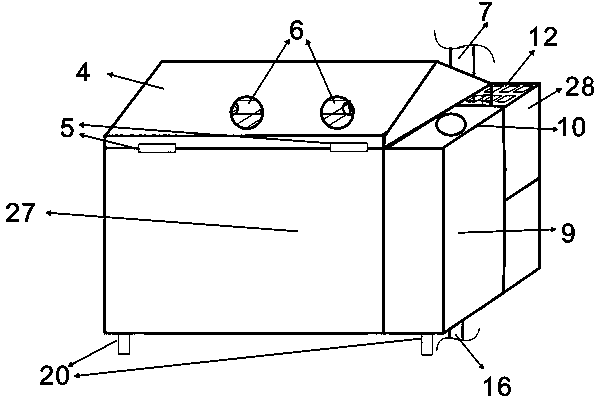

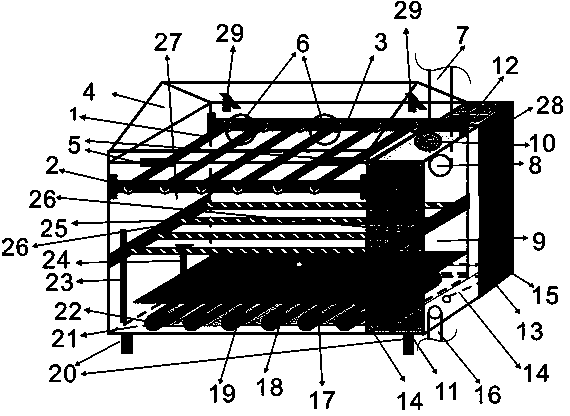

[0022] The invention relates to an accelerated corrosion box for simulating marine atmospheric corrosion, which mainly consists of a main body 27 of the accelerated corrosion box, a cover 4 of the accelerated corrosion box, a liquid storage tank 9 , a control panel 12 and a power distribution cabinet 28 .

[0023] The salt spray test in the present invention can be carried out with reference to ASTM B117-97—Standard Practice for Operating Salt Spray Apparatus, GB10125-1997 "Artificial Atmosphere Corrosion Test-Salt Spray Test" and other equivalent standards.

[0024] The test chamber is composed of the main body 27 of the accelerated corrosion chamber, the lid 4 of the accelerated corrosion chamber, the liquid storage tank 9, the solution delivery system, the exhaust system, the control panel 12, the power distribution cabinet 28 and the adjustable feet 20, and the salt spray system It is composed of infusion conduit 14, compressed air inlet 15, gas conduit 17, and nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com