Functional circuit test system and method for printed circuit board assembly

A technology for functional testing and testing systems, applied in electronic circuit testing, measuring devices, measuring electrical variables, etc., can solve problems such as long testing time, low manual testing efficiency, empty welding or wrong parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

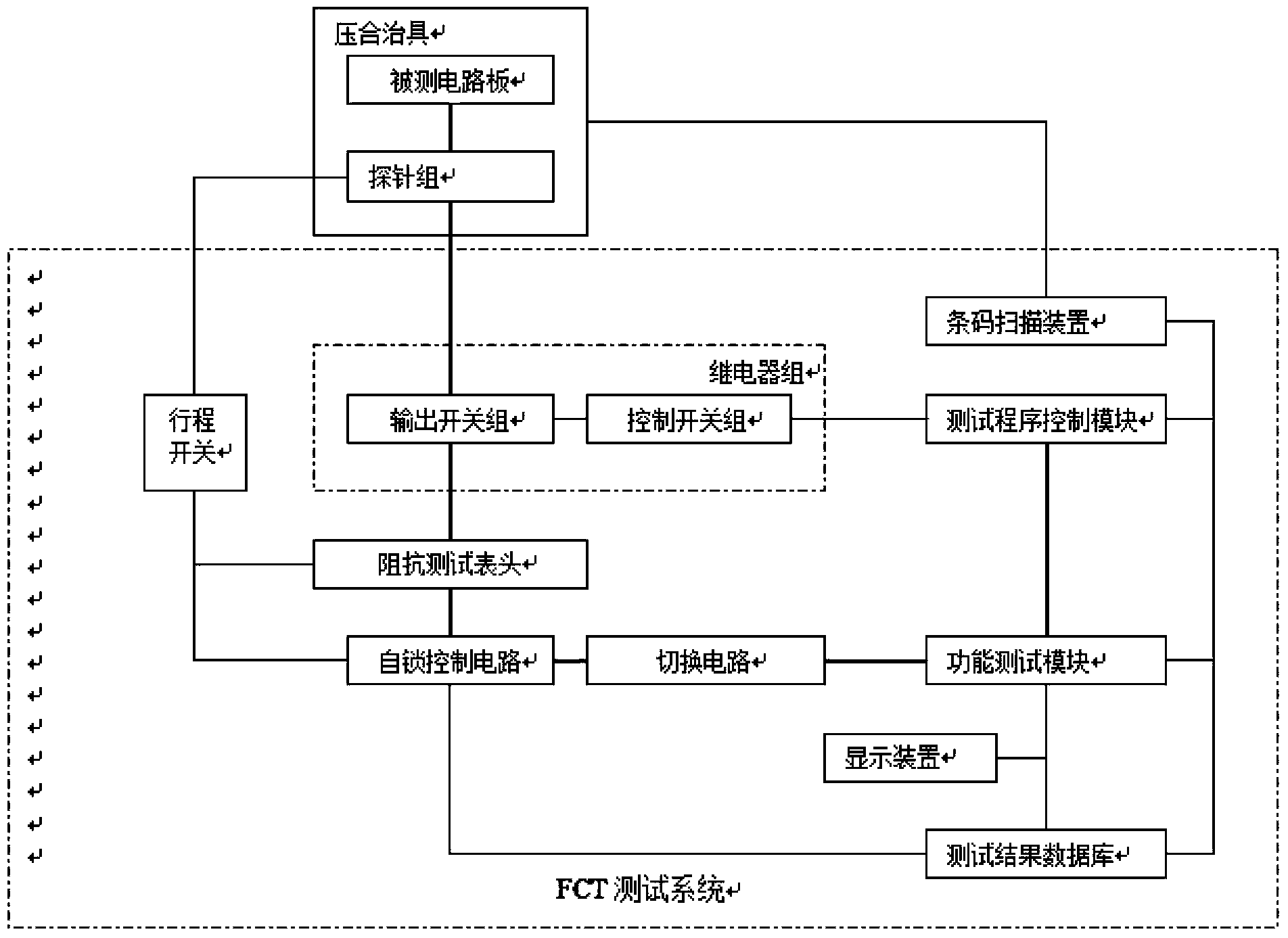

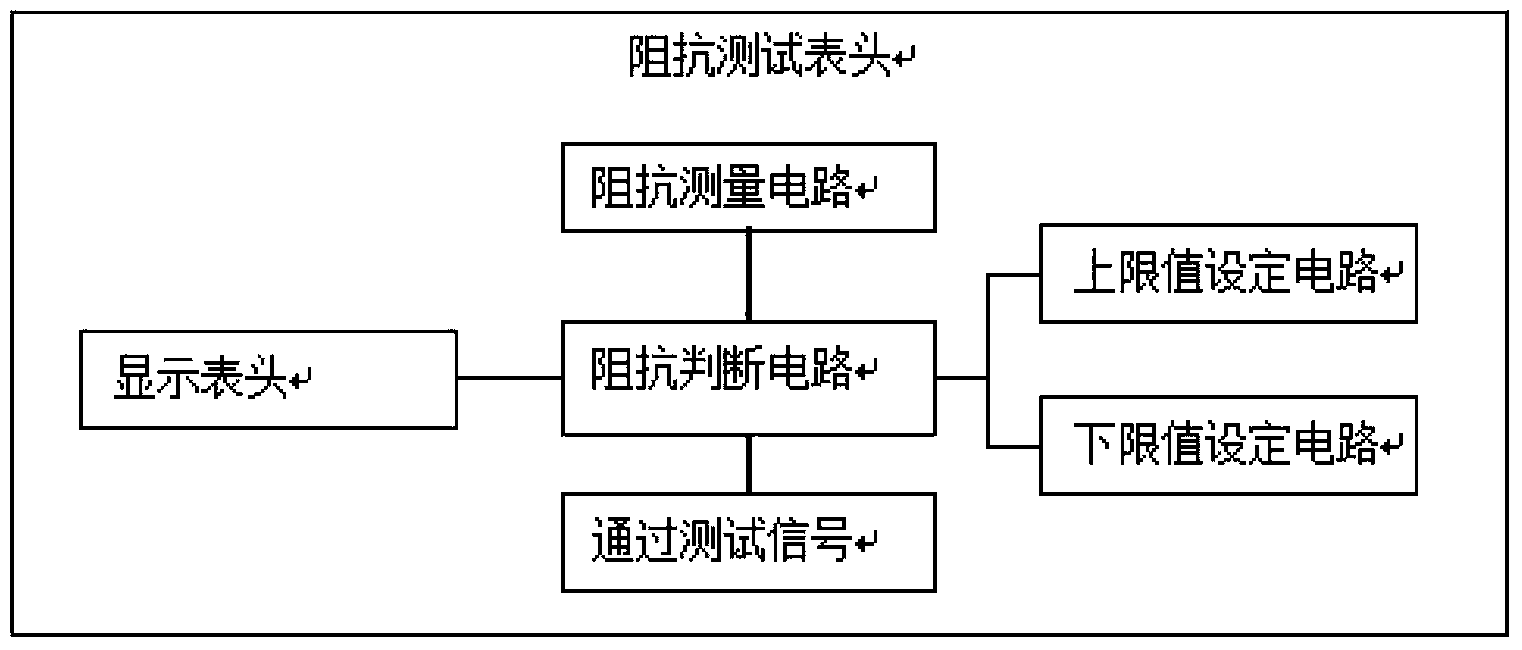

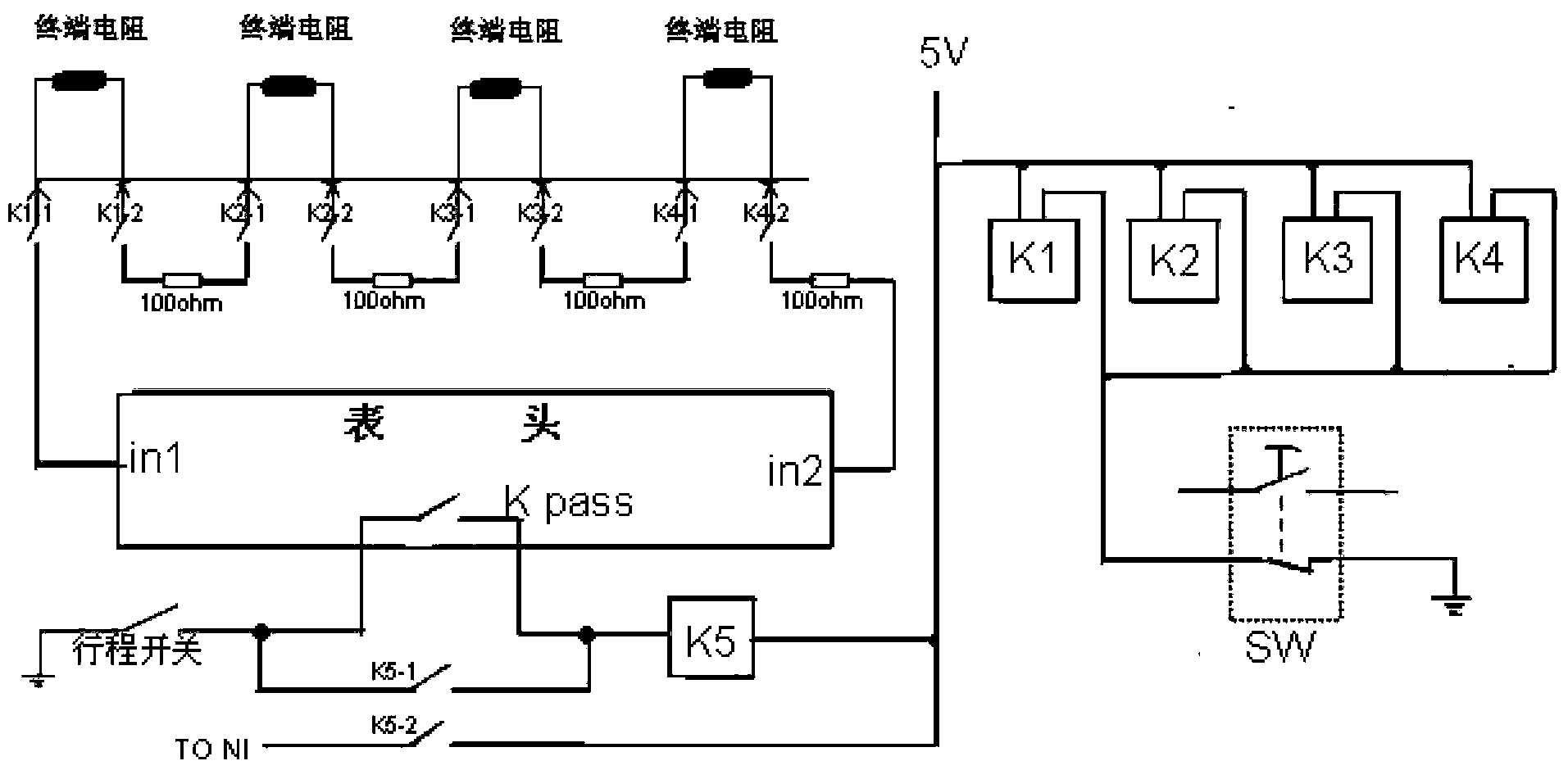

[0032] Such as figure 1 As shown, it is a functional test system for a circuit board in accordance with an embodiment of the present invention. The system includes a functional test module, including a probe set, and a press-fit fixture for testing a circuit board under test. The system Also includes: impedance test meter head, relay group, travel switch, self-locking control circuit, switching circuit, wherein,

[0033] The travel switch and the self-locking control circuit are respectively directly connected to the impedance test meter head;

[0034] The self-locking control circuit is connected to the switching circuit, and the switching circuit is connected to the functional testing module;

[0035] The travel switch is connected to the probe set of the press-fit fixture, and is used to determine whether the tested circuit board and the probe set of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com