LED (Light Emitting Diode) packaging structure and process

An LED packaging and process technology, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of low light output and low adhesion of LED chips, shorten the baking and curing time, improve production efficiency, and save production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the drawings.

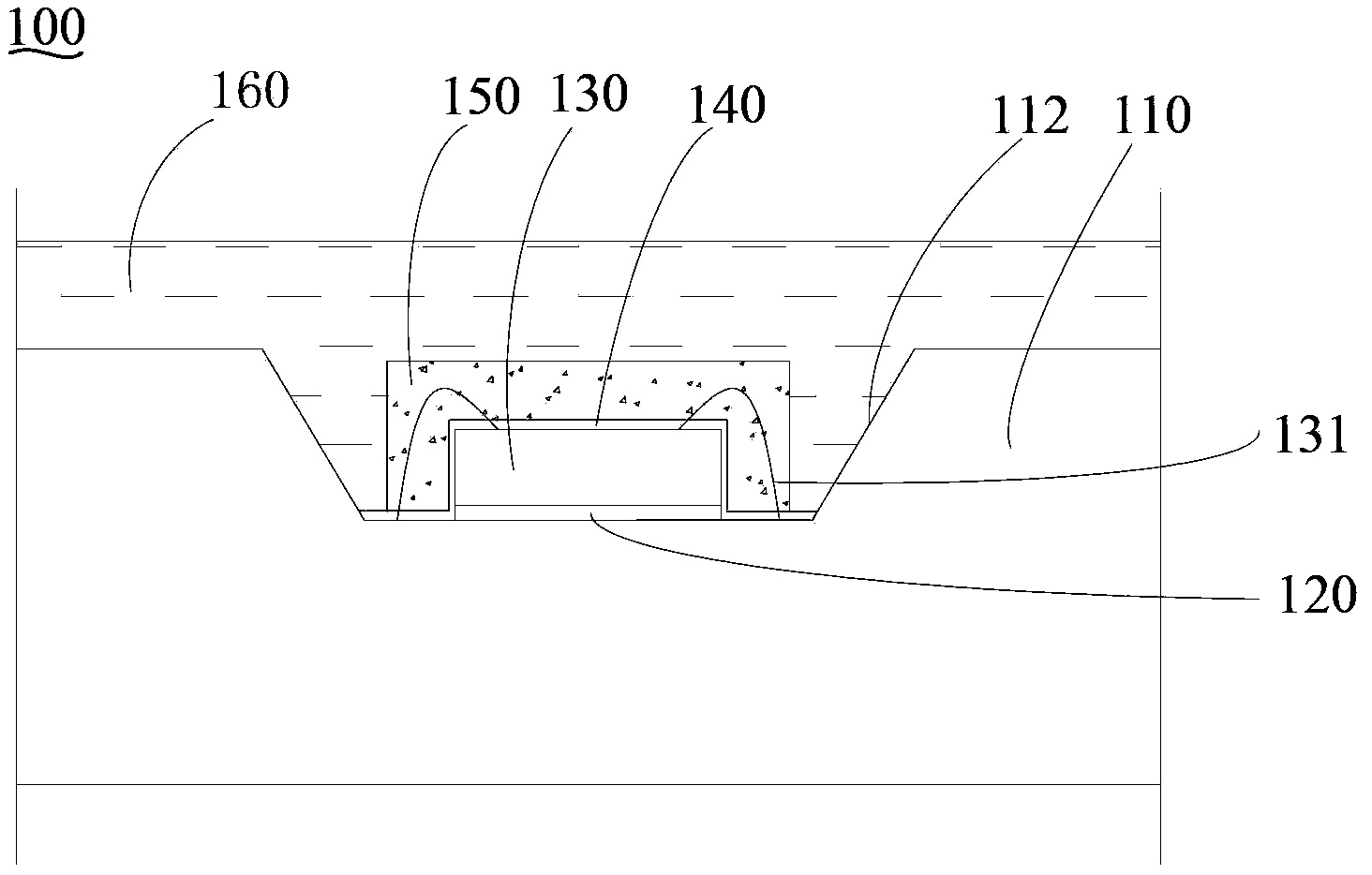

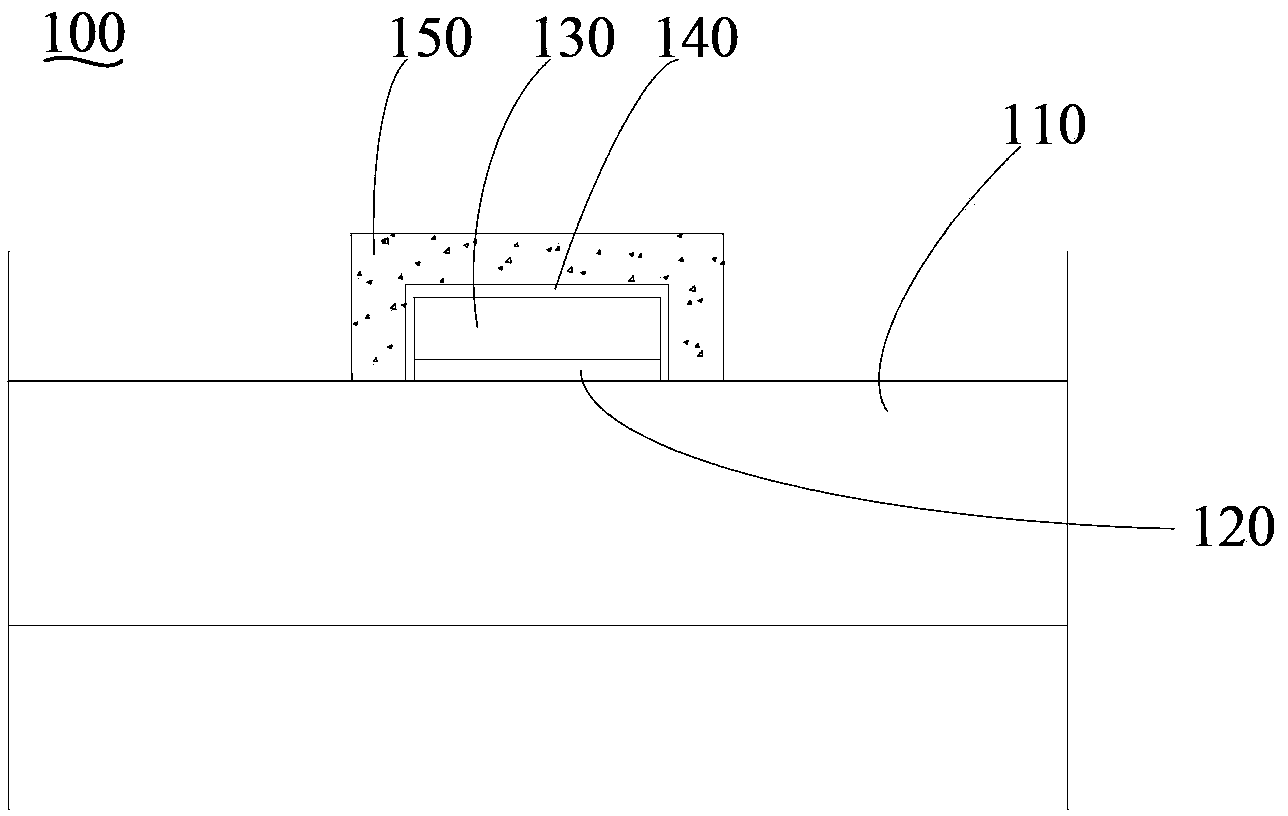

[0036] See figure 1 , An LED packaging structure 100 includes a bracket 110, a die bonding layer 120, an LED chip 130, a primer layer 140, an elastic fluorescent glue layer 150, and a packaging glue layer 160.

[0037] The bracket 110 is provided with a bowl and cup structure 112. The bottom of the bowl structure 112 is a die bonding area. The bowl-cup structure 112 can improve the light-emitting effect of the LED packaging structure 100 to a certain extent, and when the LED packaging structure 100 needs to be filled with packaging glue, the bowl-cup structure 112 is convenient for filling with packaging glue.

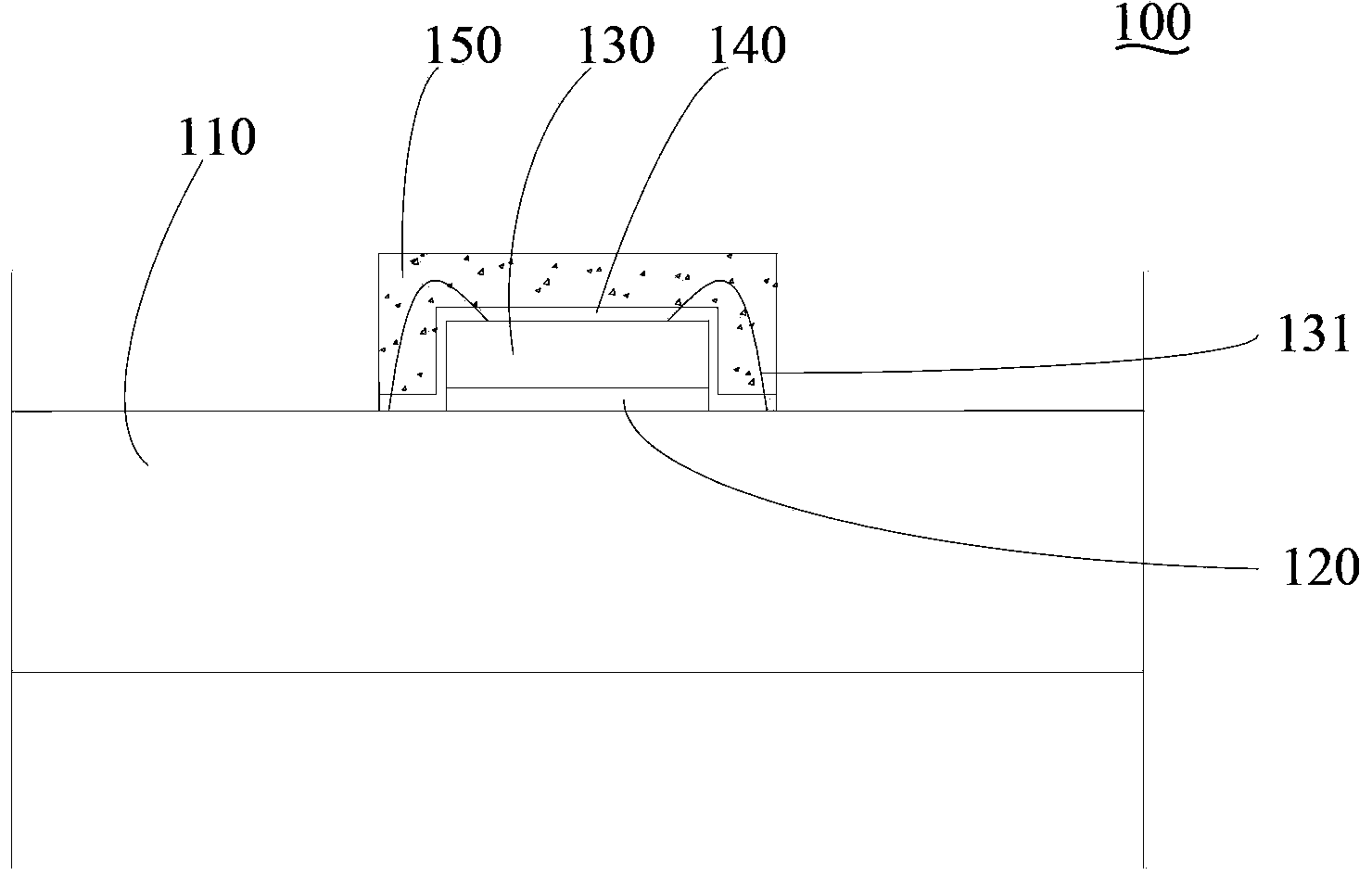

[0038] It can be understood that the bowl structure 112 can be omitted. See figure 2 , The surface of the support 110 is provided with a die bonding area.

[0039] The die bonding layer 120 is coated on the surface of the die bonding zone. The die bonding layer 120 is used to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com