Wavelength adjusting device

A wavelength adjustment and temperature sensor technology, applied in the field of spectral testing, can solve the problems of inability to meet laser working efficiency and power stability, low control accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

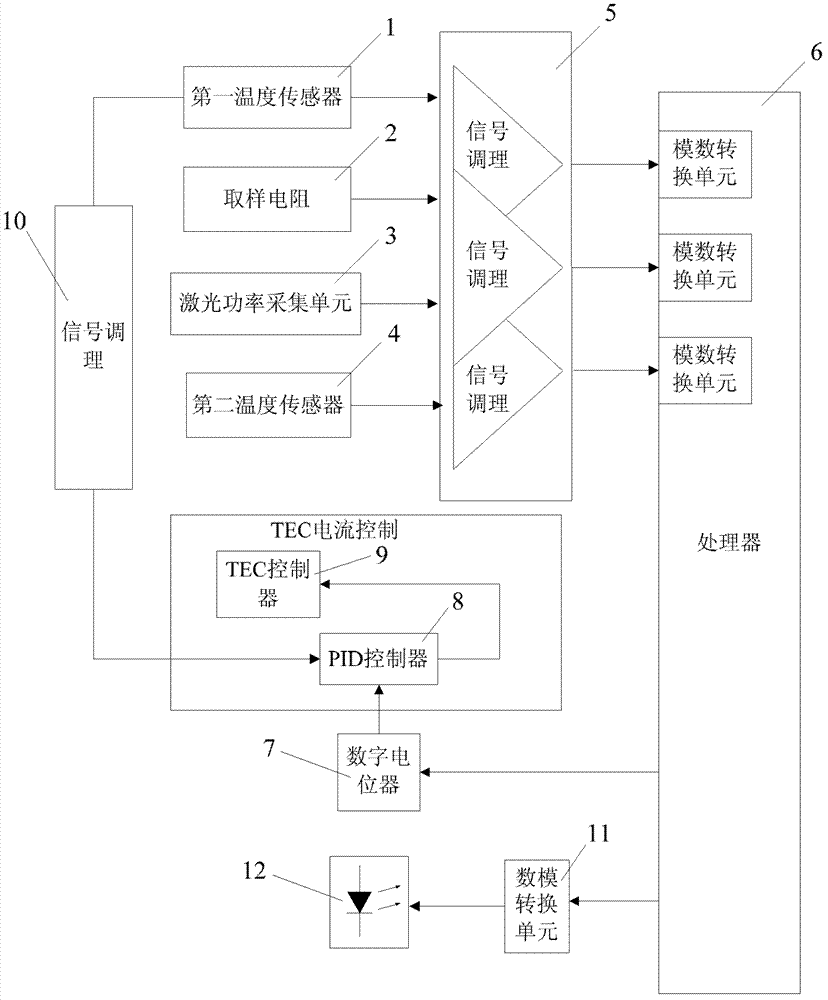

[0007] In order to facilitate a further understanding of the wavelength adjustment device of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

[0008] refer to figure 1 As shown, the wavelength adjustment device of the present invention includes: a first temperature sensor 1, used to collect the temperature of the pump surface; a sampling resistor 2, connected to the input end of the pump power supply, used to collect the pump working current; a laser The power collection unit 3 is arranged at the laser transmitting end to collect the laser power. The laser power collection unit 3 first decomposes the emitted laser light into an output laser and a detection laser through a beam splitter, and then cooperates with a photoelectric conversion unit to receive the laser power. The above detection laser is converted into an electrical signal output; a second temperature sensor 4 is used to collect the externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com