Semiconductor component sorting system

A sorting system, semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, sorting, etc., can solve problems such as time extension, test tray T transportation, etc., to prevent delays, prevent waste, and improve ease and configuration. The effect of degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, preferred embodiments of the semiconductor device sorting system of the present invention will be described in detail with reference to the accompanying drawings.

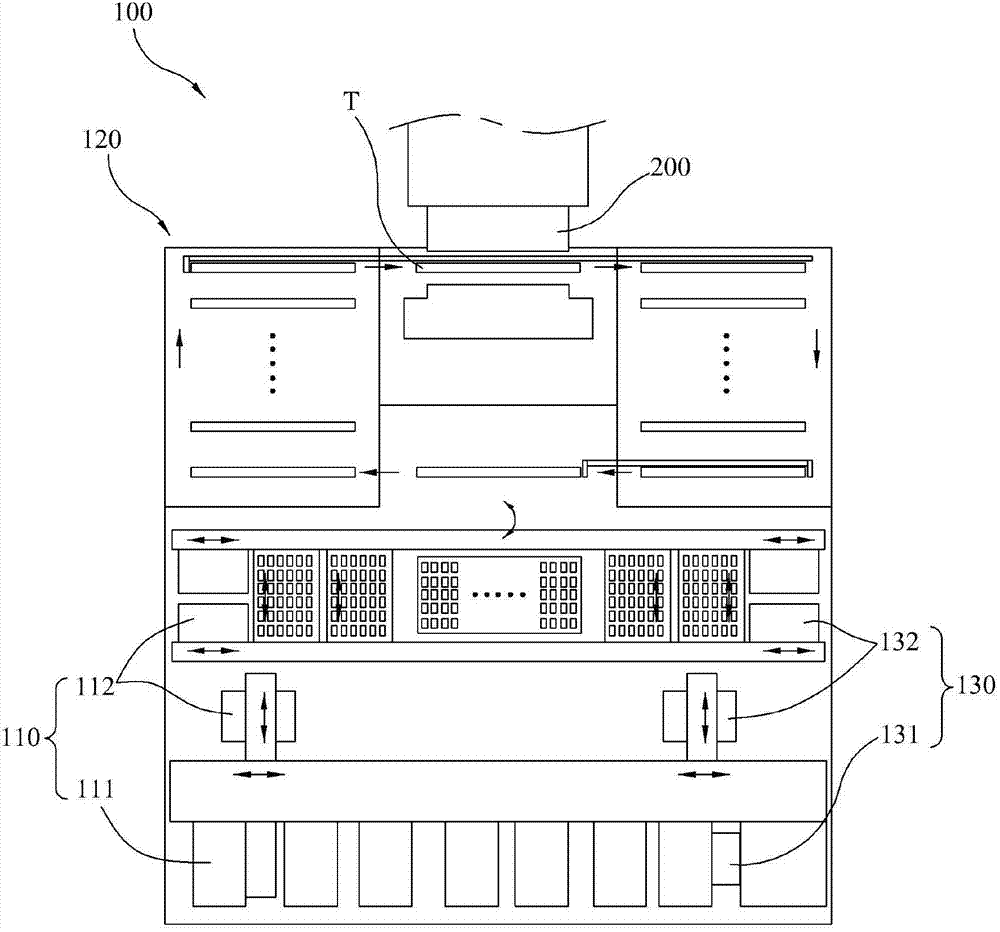

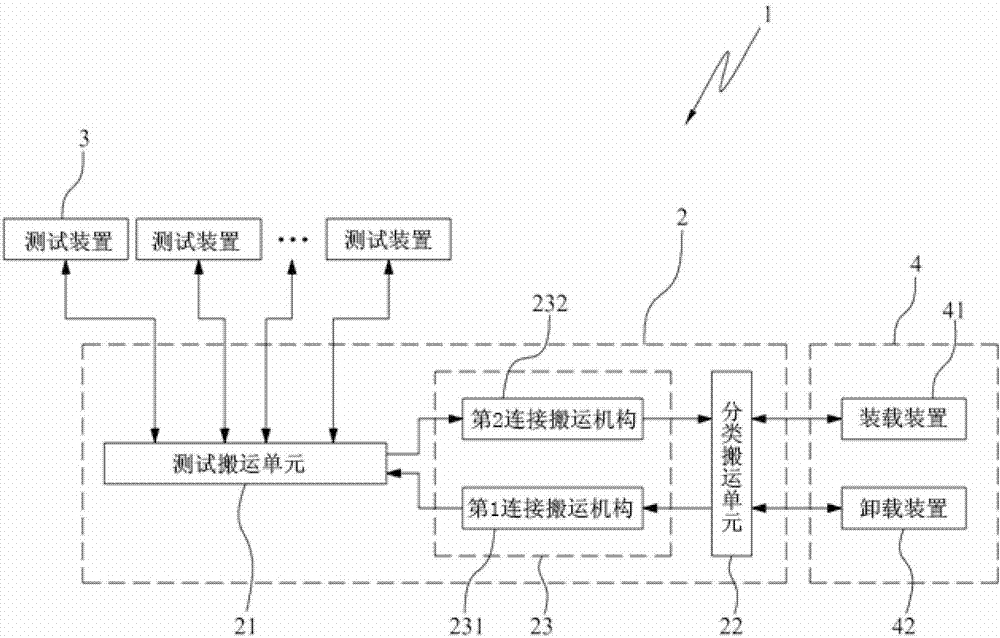

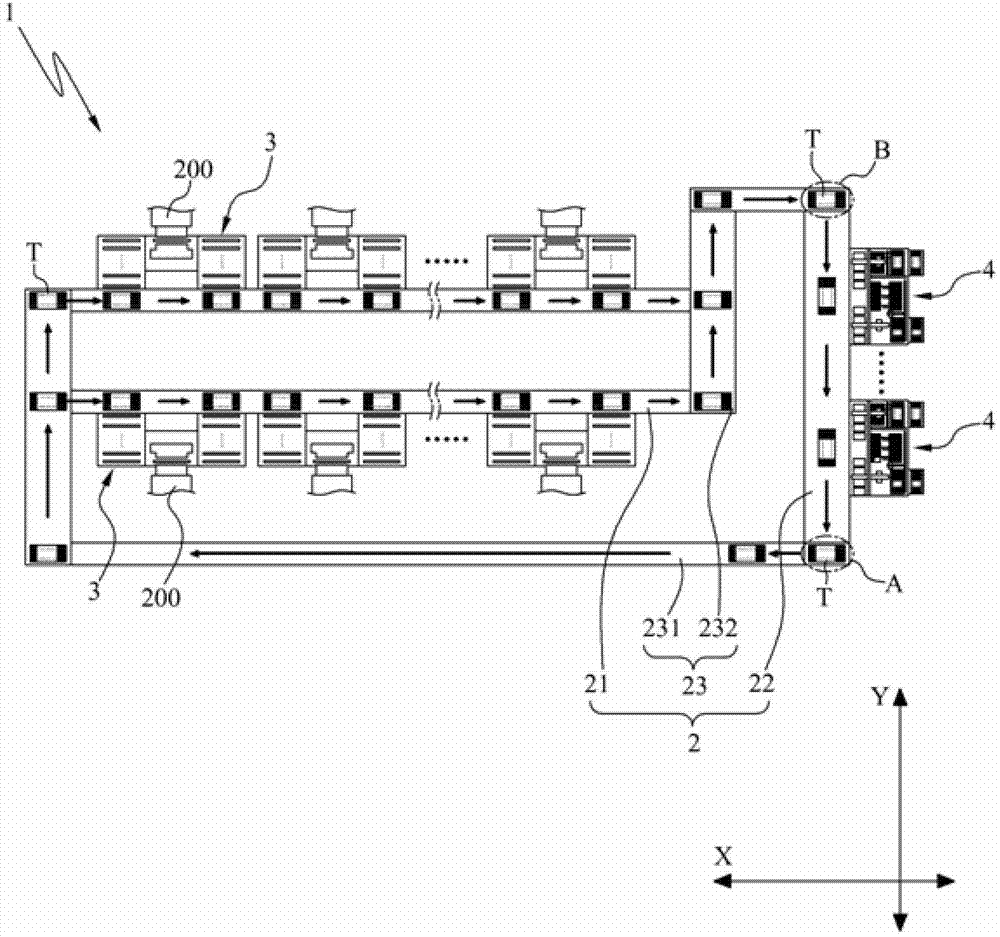

[0047] refer to figure 2 and image 3 , the semiconductor component sorting system 1 of the present invention includes: a transport device 2 for transporting the test tray T, a test device 3 for performing a test process to connect the semiconductor components accommodated in the test tray T to the test equipment 200, and the above-mentioned The testing device 3 is separated from the sorting device 4 provided.

[0048]The above-mentioned sorting device 4 executes a loading step of storing semiconductor elements to be tested in the test tray T and an unloading step of separating the tested semiconductor elements from the test tray T. As shown in FIG. The semiconductor component sorting system 1 of the present invention includes N (N is an integer greater than 0) sorting devices 4 and M (M is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com